Wolfberry fruit extract without low-melting-point impurities and preparation method thereof

A technology of wolfberry extract and low melting point, which is applied in the directions of medical preparations, pharmaceutical formulas, plant raw materials, etc. containing active ingredients, to achieve the effect of benefiting human health, benefiting interests and great application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

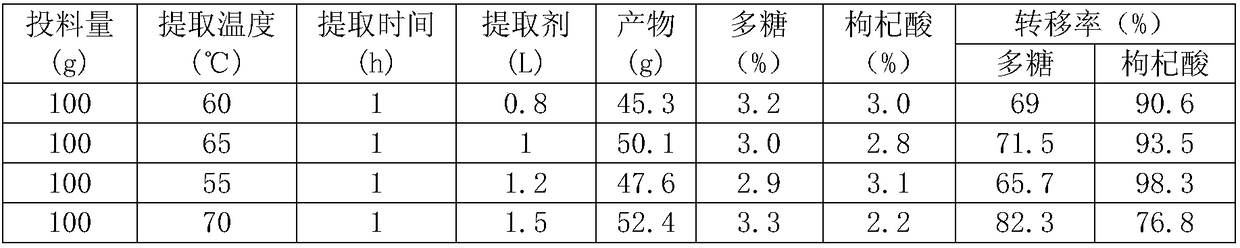

Image

Examples

Embodiment 1

[0033] Take 5 kg of dried wolfberry fruit produced in Ningxia, rinse with reverse osmosis drinking pure water to remove floating dust. Use reverse osmosis drinking pure water to extract, the dosage is 50kg each time, after beating, statically extract for 1 hour, and the extraction temperature is 60°C. The material liquid extracted by immersion is filtered in situ. The combined extracts were filtered with a 0.1 μm fine filter membrane. The collected filtrate is concentrated in vacuum, (QN-300 spherical vacuum concentration), the vacuum concentration parameter is -0.093~-0.098 MPa 50~60. Concentrate to 6805g of solid content 35% liquid. Mix the concentrated feed solution evenly with 12kg of neutral chromatographic alumina (100-200 mesh), and send it to a digital blast drying oven for drying. The equipment model is GZX-9140MBE. The dry matter is pulverized in an equipment model of XL20B withholding and swinging pulverizer, and all pass through a 40-mesh sieve. Collect the sie...

Embodiment 2

[0036]Weigh 5 kg of dried fruit of Lycium barbarum produced in Ningxia, rinse with reverse osmosis drinking pure water to remove floating dust. Use reverse osmosis drinking pure water to extract, the dosage is 50kg each time, after beating, statically extract for 1 hour, and the extraction temperature is 60°C. The material liquid extracted by immersion is filtered in situ. The combined extracts were filtered with a 0.1 μm fine filter membrane. The collected filtrate is concentrated in vacuum, and the vacuum concentration condition is -0.093~-0.098 MPa 50~60. Concentrate to 7235g of solid content 34% liquid. Evenly mix the concentrated feed solution with 7.5kg of neutral chromatography silica gel (100-200 mesh), send it into a blast oven and dry it at 40°C for 48 hours, take out the dried material and pulverize it and pass it through a 40-mesh sieve. Collect the sieved material and add 63 kg of 85% ethanol and mix well to drive away the air bubbles to form a slurry. The slur...

Embodiment 3

[0039] Weigh 5 kg of dried fruit of Lycium barbarum produced in Ningxia, rinse with reverse osmosis drinking pure water to remove floating dust. Use reverse osmosis drinking pure water to extract, the dosage is 50kg each time, after beating, statically extract for 1 hour, and the extraction temperature is 60°C. The material liquid extracted by immersion is filtered in situ. The combined extracts were filtered with a 0.1 μm fine filter membrane. The collected filtrate is concentrated in vacuum, and the vacuum concentration condition is -0.093~-0.098 MPa 50~60. Concentrate to 6768g of solid content 36.2%. Evenly mix the concentrated feed liquid with 24.5kg of log fiber powder, send it into a blast oven and dry it at 40°C for 48 hours, take out the dried material and pulverize it and pass it through a 40-mesh sieve. Collect the sieved material and add 162 kg of 82% isopropanol and mix well to drive off the air bubbles to form a slurry, and pour the slurry into a chromatography...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com