A kind of refractory brick for blast furnace slag high temperature carbonization electric furnace and preparation method thereof

A technology of high-temperature carbonization and refractory bricks, which is applied in the field of refractory materials, can solve the problems of fast erosion, no slag hanging, and low service life, and achieve excellent chemical stability and wear resistance, improve high temperature resistance, and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

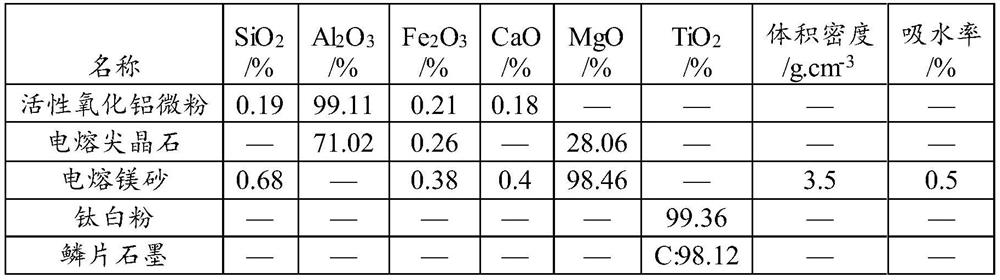

Image

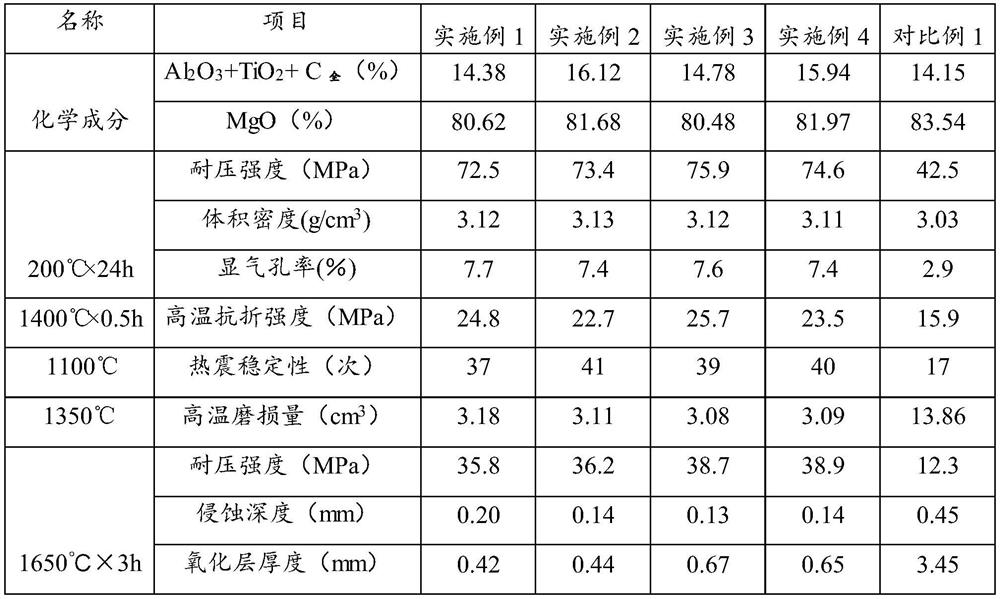

Examples

preparation example Construction

[0061] The present invention also provides a method for preparing refractory bricks for high-temperature carbonization of blast furnace slag, comprising the following steps:

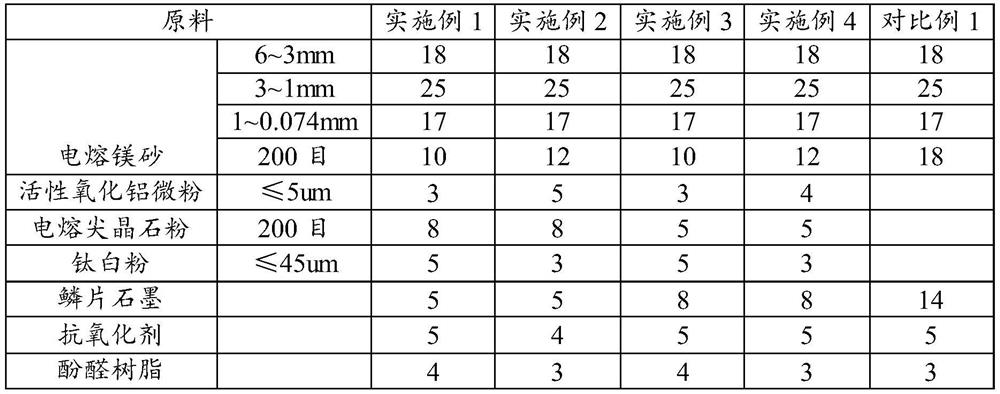

[0062] A) In terms of mass fraction, 10-12% of 200-mesh fused magnesia, 3-5% of 5 μm activated alumina micropowder, 5-8% of 200-mesh fused spinel powder, 3-5% of ≤ Mix 45μm titanium dioxide, 4-5% antioxidant and 3-4% phenolic resin, and discharge it for later use;

[0063] B) Add 15-20% of 6-3mm fused magnesia, 20-30% of 3-1mm fused magnesia and 15-20% of 1-0.074mm fused magnesia to the mixture in step A) Mixing in the medium for 2-3 minutes, then adding an organic binder, then adding 5-8% flake graphite, mixing and milling for 5-10 minutes, and discharging;

[0064] C) making bricks from the mixed material in the step B), curing naturally for more than 24 hours, and drying to obtain refractory bricks for high-temperature carbonization of blast furnace slag.

[0065] In the present invention, the types...

Embodiment 1

[0074] The present embodiment adopts the raw material proportioning in table 2;

[0075] Put the fine powder other than flake graphite into the pre-mixer in proportion and mix it for 10 minutes, then discharge it for later use;

[0076] Then pour the three kinds of magnesia granular aggregates into the high-speed mixer in proportion, after mixing for 2 minutes, add an organic binder to wet the aggregate, continue mixing for 2 minutes, add flake graphite and mix for 3 minutes, and finally add The pre-mixed mixed powder is fully mixed and milled for 5 minutes, and the bricks are made with a brick press of more than 630 tons. The finished bricks are naturally cured for more than 24 hours, dried at 180°C for more than 24 hours, sorted and packaged.

Embodiment 2

[0078] The present embodiment adopts the raw material proportioning in table 2;

[0079] Put the fine powder other than flake graphite into the pre-mixer in proportion and mix it for 12 minutes, then discharge it for later use;

[0080] Then pour the three kinds of magnesia granular aggregates into the high-speed mixer in proportion, and after mixing for 3 minutes, add an organic binder to wet the aggregate, continue mixing for 3 minutes, add flake graphite and mix for 4 minutes, and finally add The pre-mixed mixed powder is fully mixed and milled for 7 minutes, and the bricks are made with a brick press of more than 630 tons. The finished bricks are naturally cured for more than 24 hours, dried at 200°C for more than 24 hours, sorted and packaged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com