Water retaining agent and preparation method thereof

A technology of water-retaining agent and initiator, applied in the direction of chemical instruments and methods, applications, organic fertilizers, etc., can solve the problems of difficult formation of water-retaining layer, poor effect of anti-seepage and fertilizer retention, etc., and achieve strong viscoelasticity and convenient Effect of granulation and high water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

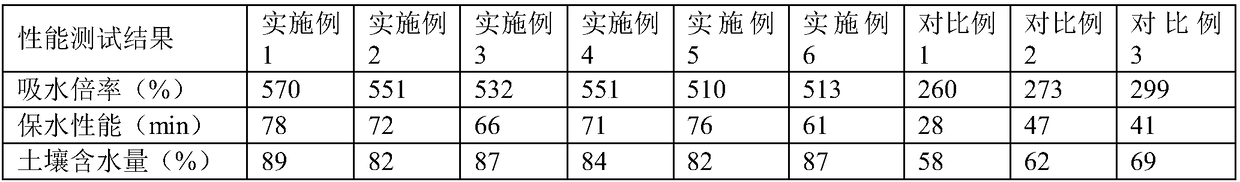

Examples

Embodiment 1

[0028] S1: Add 110 kg of acrylic acid, 80 kg of 1,3-diaminocarbazide, 7 kg of hydrogen peroxide, and 120 kg of water into the autoclave. The temperature of the autoclave is 100°C, the stirring speed is 35r / min, and the uniform stirring is 135 min. The concentration of S2 is 1.2g / L; S2: Add 45kg of potassium chloride and 27kg of potassium dihydrogen sulfate to the autoclave, and stir evenly for 35min;

[0029] S3: Raise the temperature of the high-pressure reactor to 145°C, and the stirring speed to 54r / min, while continuously introducing carbon dioxide, the flow rate of carbon dioxide is 33m 2 / h, slowly drip 22 kg of polyoxyethylene sorbitan trioleate, 22 kg of polyoxyethylene sorbitan laurate, and 12 kg of polyacrylamide into the reaction kettle. After the addition is completed, react for 45 minutes;

[0030] S4: Increase the stirring speed of the autoclave to 66r / min, and stir uniformly for 4.5h. After the stirring is completed, reduce the temperature of the autoclave to room tem...

Embodiment 2

[0032] S1: Add 100kg of acrylic acid, 70kg of 1,3-diaminocarbazide, 5kg of hydrogen peroxide, and 140kg of water into the autoclave. The temperature of the autoclave is 110°C, the stirring speed is 30r / min, and the uniform stirring is 135min. The concentration of S2 is 1.4g / L; S2: Add 40kg of potassium chloride and 25kg of potassium dihydrogen sulfate to the high-pressure reactor, and stir evenly for 30min;

[0033] S3: Raise the temperature of the high-pressure reactor to 140°C, the stirring speed to 58r / min, and the helium gas is continuously introduced at the same time, the flow rate of the helium gas is 36m 2 / h, slowly drip 20 kg of polyoxyethylene sorbitan trioleate, 24 kg of polyoxyethylene sorbitan laurate, and 14 kg of polyacrylamide into the reaction kettle. After the addition is completed, react for 40 minutes;

[0034] S4: Increase the stirring speed of the autoclave to 64r / min, and stir uniformly for 4 hours. After the stirring is completed, reduce the temperature of th...

Embodiment 3

[0036] S1: Add 120kg of acrylic acid, 70kg of 1,3-diaminocarbazide, 5kg of potassium persulfate, and 140kg of water into the autoclave. The temperature of the autoclave is 90℃, the stirring speed is 40r / min, and the uniform stirring is 150min. The concentration is 1g / L;

[0037] S2: Add 40 kg of potassium chloride and 29 kg of potassium dihydrogen sulfate to the high-pressure reaction vessel, and stir evenly for 30 minutes;

[0038] S3: Raise the temperature of the high-pressure reactor to 140°C, and the stirring speed to 58r / min, while continuously introducing carbon dioxide, the flow of carbon dioxide is 30m 2 / h, slowly drip 24 kg of polyoxyethylene sorbitan trioleate, 24 kg of polyoxyethylene sorbitan laurate, and 14 kg of polyacrylamide into the reaction kettle. After the addition is complete, react for 40 minutes;

[0039] S4: Increase the stirring speed of the autoclave to 68r / min, and stir uniformly for 4 hours. After the stirring is completed, reduce the temperature of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com