Three-component sound-absorbing cotton capable of generating negative ions and efficiently adsorbing formaldehyde and VOC

A technology for adsorbing formaldehyde and negative ions, which is applied in the field of sound-absorbing materials, can solve the problems of small specific surface area of granular activated carbon, affect the environmental sanitation in the car, and slow adsorption and desorption, so as to achieve obvious removal, good full-frequency sound-absorbing ability, and improve physical fitness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

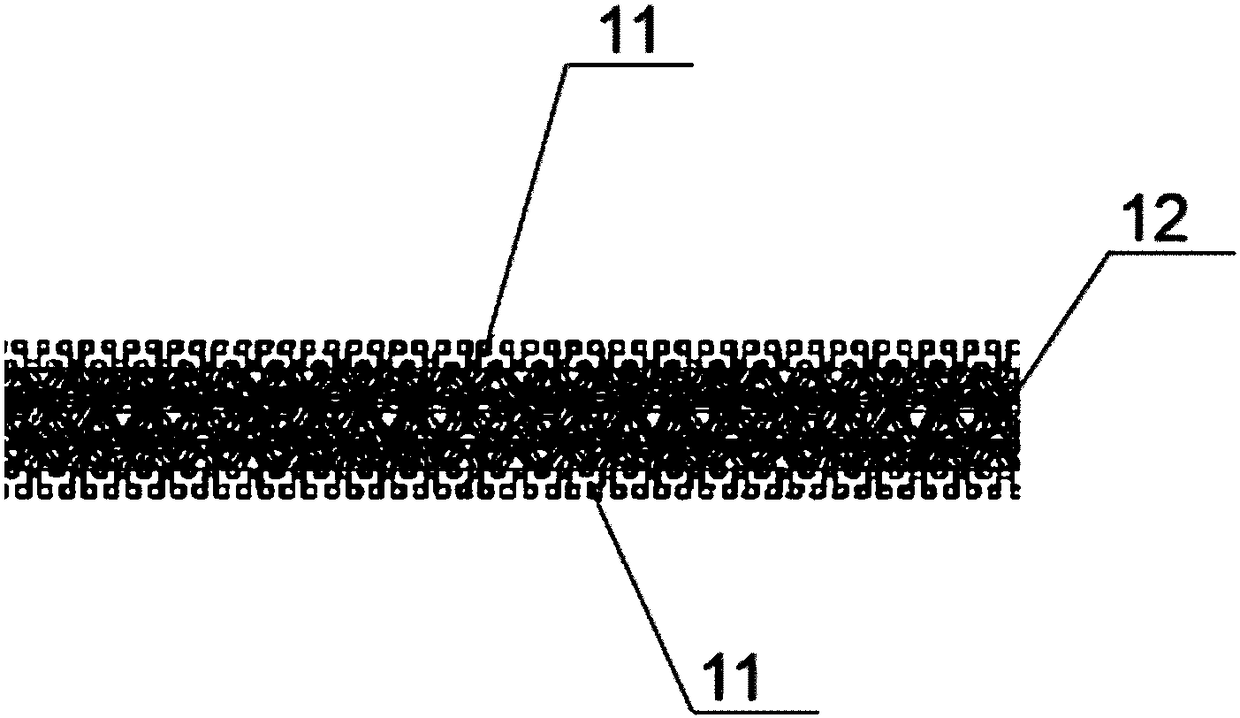

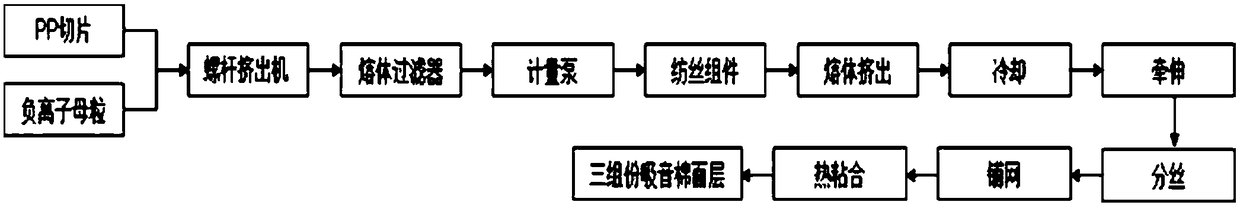

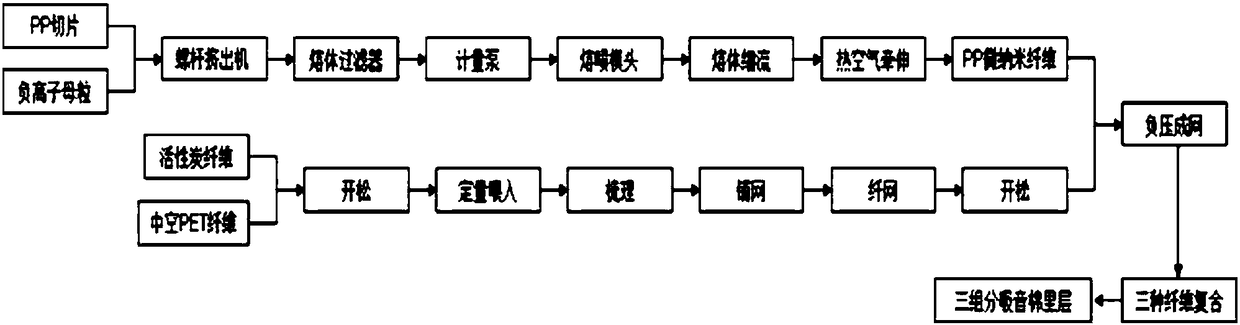

[0025] see Figure 1-Figure 4 , in the embodiment of the present invention, a three-component sound-absorbing cotton that generates negative ions and efficiently absorbs formaldehyde and VOC is composed of a surface layer 11 and a composite layer 12. Both sides of the composite layer 12 cover the surface layer 11, and the surface layer 11 uses PP negative ions Non-woven fabric or aluminum foil or other attachments may also have no surface layer 21 . When the surface layer 11 is made of PP negative ion non-woven fabric, it is made of PP negative ion spun-bonded filaments through thermal bonding and reinforcement, and belongs to the filament web structure, with a thickness of 0.5-1mm.

[0026] The proportion of the PP negative ion non-woven fabric of the surface layer 11: 100 parts of PP chips (melt index 50-80g / 10min, isotacticity 95%), 2 parts of negative ion PP masterbatch, 1 part of cooling masterbatch.

[0027] The proportion of the negative ion PP masterbatch: 100 parts o...

Embodiment 2

[0033] In the embodiment of the present invention, a three-component sound-absorbing cotton that generates negative ions and efficiently absorbs formaldehyde and VOC is composed of a surface layer 11 and a composite layer 12. Both sides of the composite layer 12 cover the surface layer 11. Spun cloth or aluminum foil. When the surface layer 11 is made of PP negative ion non-woven fabric, it is made of PP negative ion spun-bonded filaments through thermal bonding and reinforcement, and belongs to the filament web structure, with a thickness of 0.5-1 mm.

[0034] The proportion of the PP negative ion non-woven fabric of the surface layer 11: 100 parts of PP chip (melt index 50-80g / 10min, isotacticity 95%), 10 parts of negative ion PP master batch, 2 parts of cooling master batch.

[0035] The proportion of the negative ion PP masterbatch: 100 parts of PP slices (melt index 50-80g / 10min, isotacticity 95%), 20 parts of tourmaline powder with particle size less than 100nm. The pre...

Embodiment 3

[0042] In the embodiment of the present invention, a three-component sound-absorbing cotton that generates negative ions and efficiently absorbs formaldehyde and VOC is composed of a surface layer 11 and a composite layer 12. Both sides of the composite layer 12 cover the surface layer 11. Spun cloth or aluminum foil. When the surface layer 11 is made of PP negative ion non-woven fabric, it is made of PP negative ion spun-bonded filaments through thermal bonding and reinforcement, and belongs to the filament web structure, with a thickness of 0.5-1mm.

[0043] The proportion of the PP negative ion non-woven fabric of the surface layer 11: 100 parts of PP chips (melt index 50-80g / 10min, isotacticity 95%), 5 parts of negative ion PP masterbatch, and 1.5 parts of cooling masterbatch.

[0044] The proportion of the negative ion PP masterbatch: 100 parts of PP slices (melt index 50-80g / 10min, isotacticity 95%), 10 parts of tourmaline powder with particle size less than 100nm. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com