Filler for high-efficiency anti-clogging bioretention system

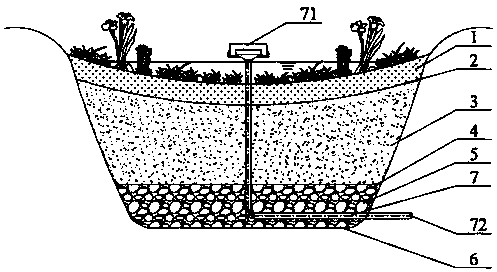

A bioretention and anti-clogging technology, applied in biological water/sewage treatment, granular microbial carrier treatment, water pollutants, etc. Filling soil is prone to blockage and other problems, so as to achieve the effects of water retention capacity, non-toxic and tasteless, improved removal capacity, and improved percolation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of biological ceramsite is as follows:

[0020] (1) Preparation of biological ceramsite shell:

[0021] S1. Use municipal dry sludge, ferric chloride, fly ash and clay to mix to obtain powder, ferric chloride is 1.0% of the weight of municipal dry sludge, and fly ash is 120% of the weight of municipal dry sludge. The clay is 50% of the weight of the municipal dry sludge, and the particle size of the powder is less than or equal to 0.09mm; the polystyrene foam particles are used as the template, the polystyrene foam is a sphere, and the particle size of the template is 2~8mm; the water content of the municipal dry sludge The rate is 8.0%;

[0022] S2. dipping a layer of carboxymethyl cellulose solution with a mass concentration of 1.2% on the template;

[0023] S3. Then put the template of S2. into the powder, so that the surface is covered with a layer of powder with a thickness of 0.3~0.5mm;

[0024] S4. Then put the template of S3. into the b...

Embodiment 1~7

[0034] A filler for a bioretention system, the filler includes a filler matrix and bio-ceramic, and the bio-ceramic includes a hollow bio-ceramic shell and a sodium polyacrylate superabsorbent resin filled in the bio-ceramic shell, The biological ceramsite shell is provided with 3 openings, and the filler matrix is formed by mixing cattail matrix soil and fine sand. The specific parameters are shown in Table 1.

[0035] Table 1

[0036] serial number

Embodiment 8

[0038] The difference between this example and Example 7 is that the filler matrix also contains 3% iron powder by mass of the matrix.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com