Effluent pretreatment system for rain and sewage mixed-flow type pump station

A mixed-flow and pretreatment technology, applied in the field of water treatment, can solve problems such as river pollution, achieve obvious technical effects and solve the high pollution load into the river.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

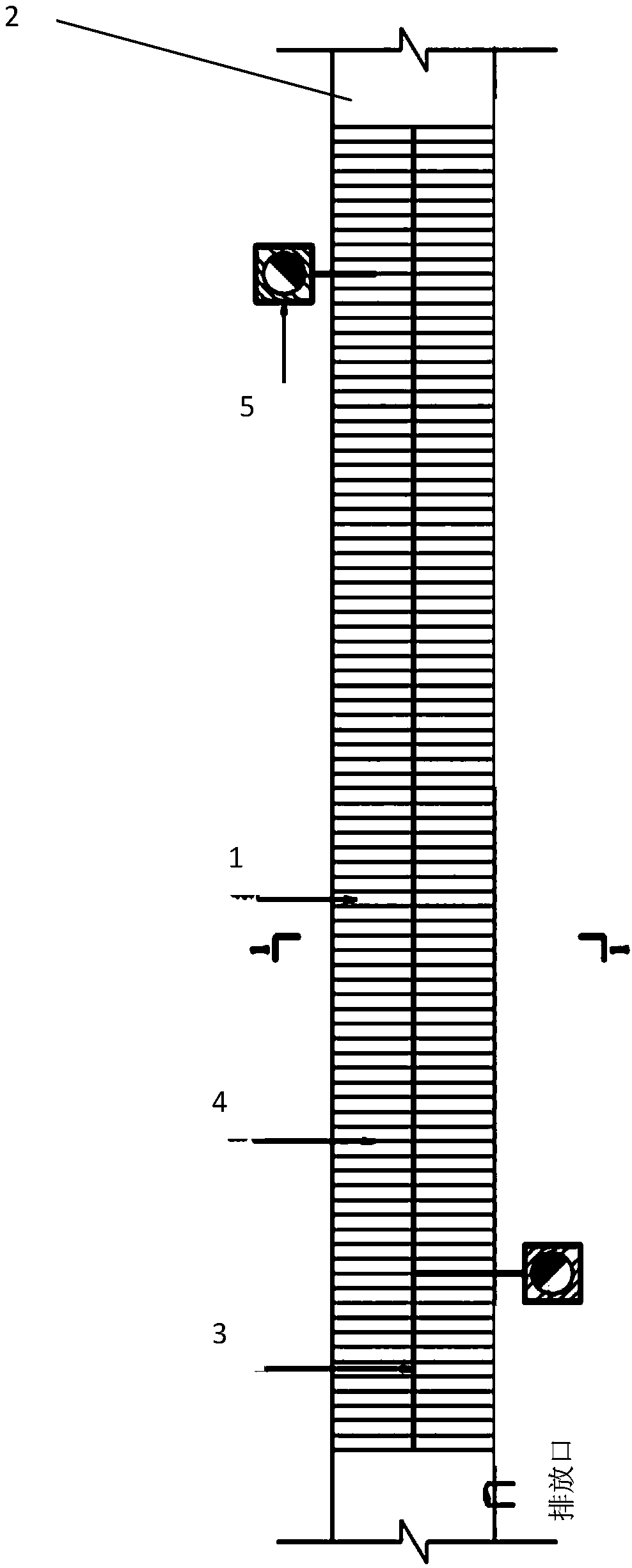

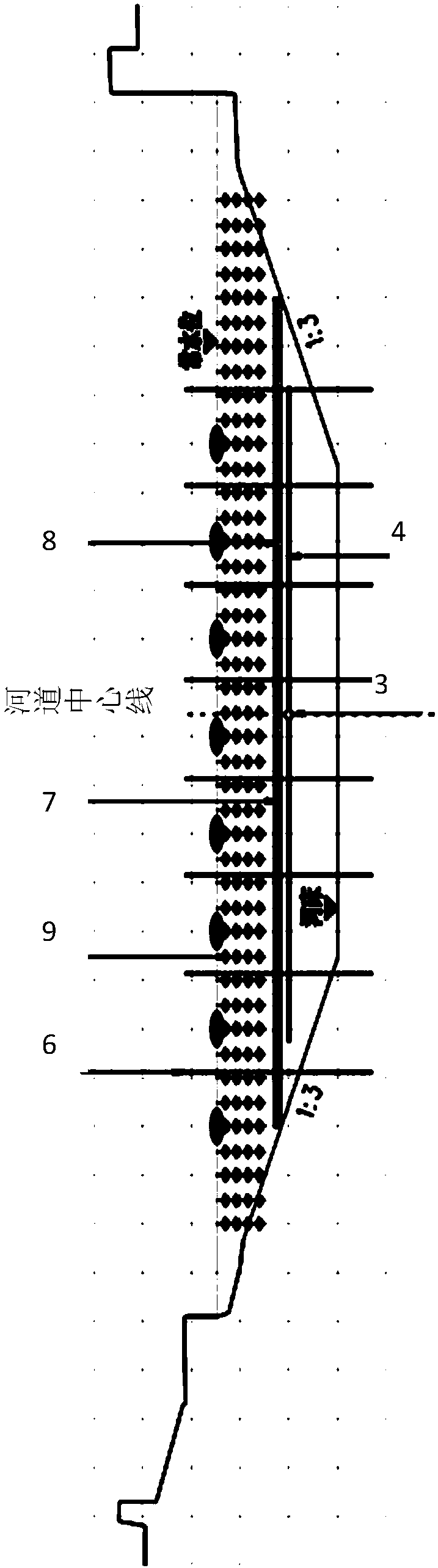

[0017] The present invention provides a rain-sewage mixed-flow pump station effluent pretreatment system, comprising an aeration system 1 and a biological film-hanging system 2, and the biological film-hanging system 2 is arranged above the aeration system 1;

[0018] The aeration system 1 includes at least one aeration device, any aeration device includes a main pipe 3 and more than two branch pipes 4, the branch pipe 4 and the main pipe 3 are vertically arranged, any one of the The main pipes 3 are all connected to a blower 5, the main pipe 3 and the branch pipe 4 are provided with more than two aeration holes, and the main pipe 3 is arranged parallel to the shoreline;

[0019] The bio-film-hanging system 2 includes more than two steel pipes 6, the bottom of the steel pipes 6 are fixedly connected to the river bottom, steel wire ropes are arranged between the steel pipes 6, and the steel wire ropes are perpendicular to the shoreline. The steel wire rope is provided with a ha...

Embodiment 2

[0027] The present invention includes "multi-row pipeline aeration system + biological film-hanging" two-part structure:

[0028] 1. Multi-row pipeline aeration system

[0029] A fixed blower room is set up in the water body, and the air is introduced into the incoming water of the Fangjiang pumping station through pipes to achieve the purpose of increasing DO for the water body. The aeration system adopts multiple rows of parallel aeration pipelines (DN50), which are arranged within 50-100 m of the water body downstream of the river pumping station (it can be adjusted according to the actual amount of river discharge). The aeration pipeline system consists of a DN75 main pipe 3 (parallel to the shoreline, connected by a blower) and multiple DN50 branch pipes 4 (perpendicular to the main pipe 3, and a branch pipe 5 is arranged every 2-3m along the direction of the main pipe 3) , the main aeration aperture is 3~5mm. The aeration pipes are fixed by DN25 hot-dip galvanized stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com