A method of solid-liquid separation stacking technology for the purification of mineral salt block salt

A solid-liquid separation and salt block technology, which is applied in separation methods, chemical instruments and methods, solid solvent extraction, etc., can solve problems such as increased production costs of salt processing and purification, increased production costs of salt processing and purification, and living environment pollution , to achieve the effect of uncomplicated device, improved purification degree and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

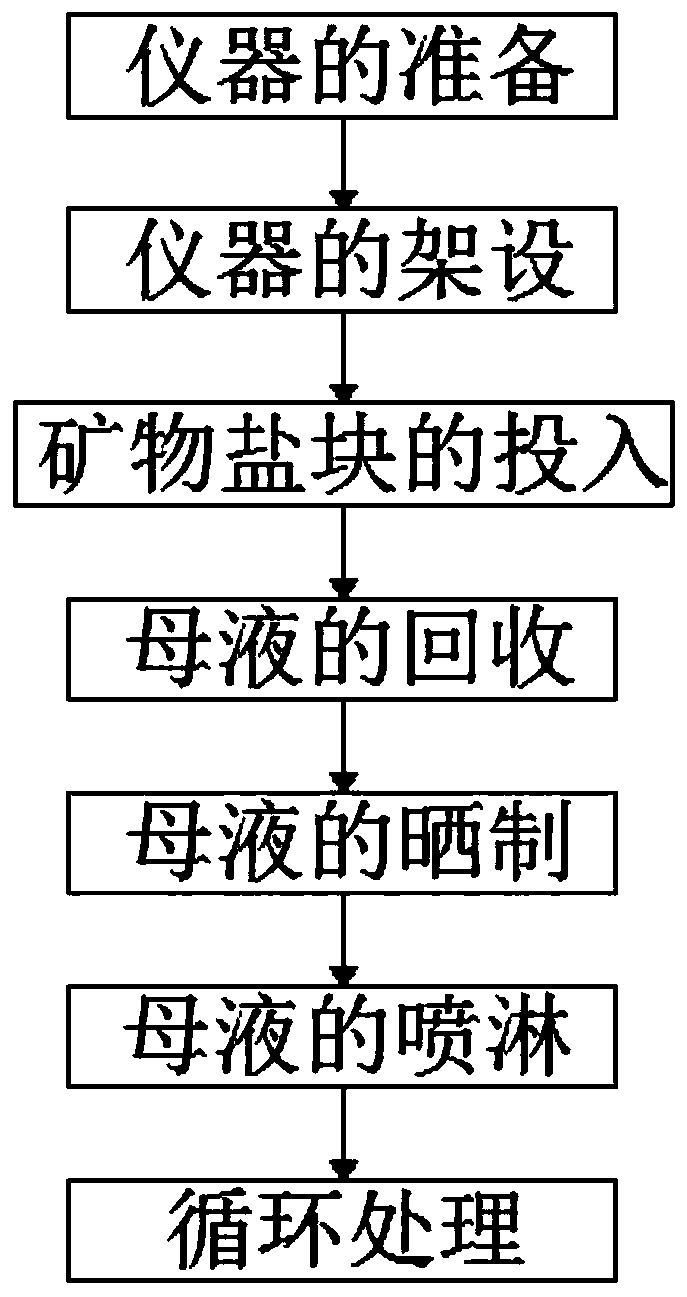

[0036] A method of solid-liquid separation stacking technology for the purification of mineral salt block salt, comprising the following steps:

[0037] 1) Preparation of the instrument: one stacking box, one reflux tank, one water pump, one water inlet pipe, one water delivery pipe, one connecting frame and one nozzle;

[0038] 2) Erection of the instrument;

[0039] 3) input of mineral salt block;

[0040] 4) recovery of mother liquor;

[0041] 5) drying of mother liquor;

[0042] 6) Spraying of mother liquor (brine);

[0043] 7) Loop processing.

[0044] In the present invention, the bottom end of the side of the stacking box is plugged with a through-pipe, and a control valve is installed on the end of the through-pipe located outside the stacking box, and a control handle is movably installed on the control valve. The construction personnel can control the control handle to limit the mother liquor The outflow of the through pipe, and the end of the through pipe locat...

Embodiment 2

[0057] A method of solid-liquid separation stacking technology for the purification of mineral salt block salt, comprising the following steps:

[0058] 1) Preparation of the instrument: one stacking box, one reflux tank, one water pump, one water inlet pipe, one water delivery pipe, one connecting frame and one nozzle;

[0059] 2) Erection of the instrument;

[0060] 3) input of mineral salt block;

[0061] 4) recovery of mother liquor;

[0062] 5) drying of mother liquor;

[0063] 6) Spraying of mother liquor (brine);

[0064] 7) Loop processing.

[0065] In the present invention, the bottom end of the side of the stacking box is plugged with a through-pipe, and a control valve is installed on the end of the through-pipe located outside the stacking box, and a control handle is movably installed on the control valve. The construction personnel can control the control handle to limit the mother liquor The outflow of the through pipe, and the end of the through pipe locat...

Embodiment 3

[0078] A method of solid-liquid separation stacking technology for the purification of mineral salt block salt, comprising the following steps:

[0079] 1) Preparation of the instrument: one stacking box, one reflux tank, one water pump, one water inlet pipe, one water delivery pipe, one connecting frame and one nozzle;

[0080] 2) Erection of the instrument;

[0081] 3) input of mineral salt block;

[0082] 4) recovery of mother liquor;

[0083] 5) drying of mother liquor;

[0084] 6) Spraying of mother liquor (brine);

[0085] 7) Loop processing.

[0086] In the present invention, the bottom end of the side of the stacking box is plugged with a through-pipe, and a control valve is installed on the end of the through-pipe located outside the stacking box, and a control handle is movably installed on the control valve. The construction personnel can control the control handle to limit the mother liquor The outflow of the through pipe, and the end of the through pipe locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com