Stirrer and equipment with stirrer

A stirrer and sensor technology, applied in the field of industrial equipment with stirrers, to achieve the effect of ensuring work stability, ensuring effective support, and reducing operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In the following, the present invention will be specifically described through exemplary embodiments. It should be understood that elements, structures and characteristics of one embodiment or example may be beneficially combined in other embodiments without further recitation.

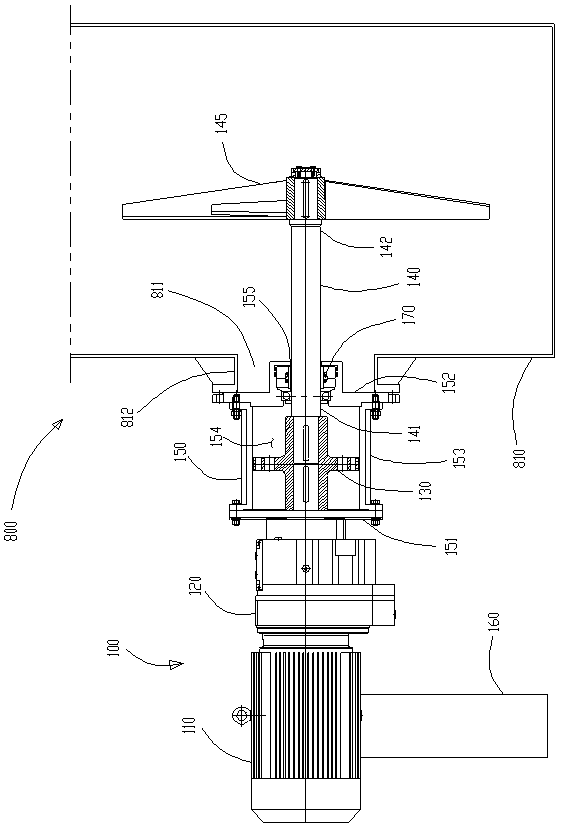

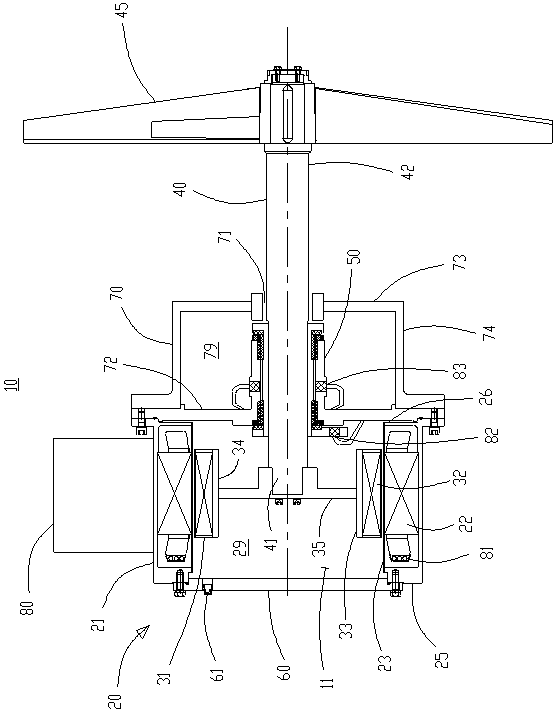

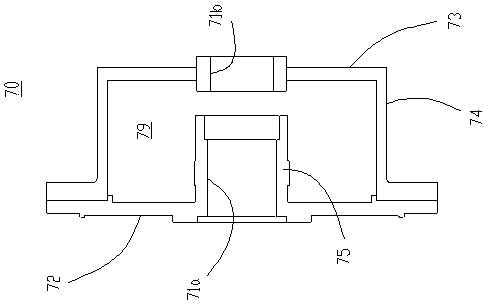

[0028] figure 2 A stirrer 10 according to one embodiment of the invention is shown. Such as figure 2As shown, the stirrer 10 includes a motor 20 , a rotating shaft 40 connected to the motor 20 , and a paddle 45 fixed to an end 42 of the rotating shaft 40 . The motor 20 includes a stator assembly 21 having a ring configuration and a rotor assembly 31 surrounded by the stator assembly 21 and forming a gap with the stator assembly 21 . The stator assembly 21 includes a stator 22 having an annular configuration, and a fully enclosed cover 23 surrounding the stator 22 . The housing 23 thus has an annular configuration similar to that of the stator 22 . The rotor assembly 31 includes a rotor 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com