Macrofluid-based microfluidic chip and preparation method thereof

A microfluidic chip and chip control technology, applied in chemical instruments and methods, foam dispersion/prevention, laboratory utensils, etc., can solve the problems of limiting the application of fluidic chips, complex micron structure manufacturing process, etc., and achieve balanced polishability , excellent printing effect, and balanced mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Step 1, Preparation of PLA positive mold of PDMS microfluidic macrofluidic chip

[0041] 1.1 Use 3D printing PLA polysmooth material to prepare the microfluidic macrofluidic chip control layer and the positive mold of the fluidic layer;

[0042] 1.2 Put the positive mold in alcohol spray for surface polishing, control layer for 30 minutes, fluid layer for 3 hours;

[0043] 1.3 Clean the control layer and fluid layer;

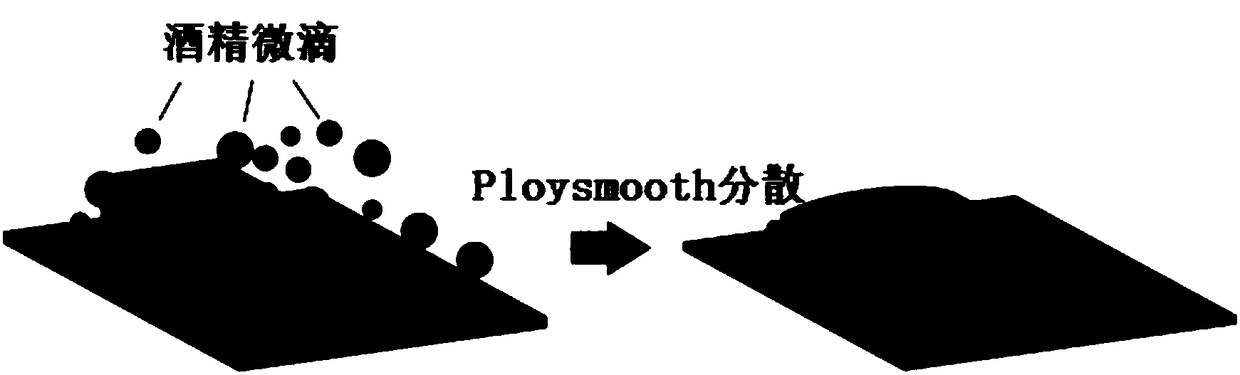

[0044] combine figure 1 , which is a schematic diagram of the 3D printed polysmooth block structure transformed into a smooth arched structure suitable for a fluidic chip pressure valve after alcohol droplet polishing. After 3D printing, the printing material polysmooth has a block structure. After alcohol droplet polishing, the block structure disappears and turns into a smooth arched structure. The surface of the 3D printed model is smoother. This smooth structure is suitable for fluid chips. Use of pressure valves.

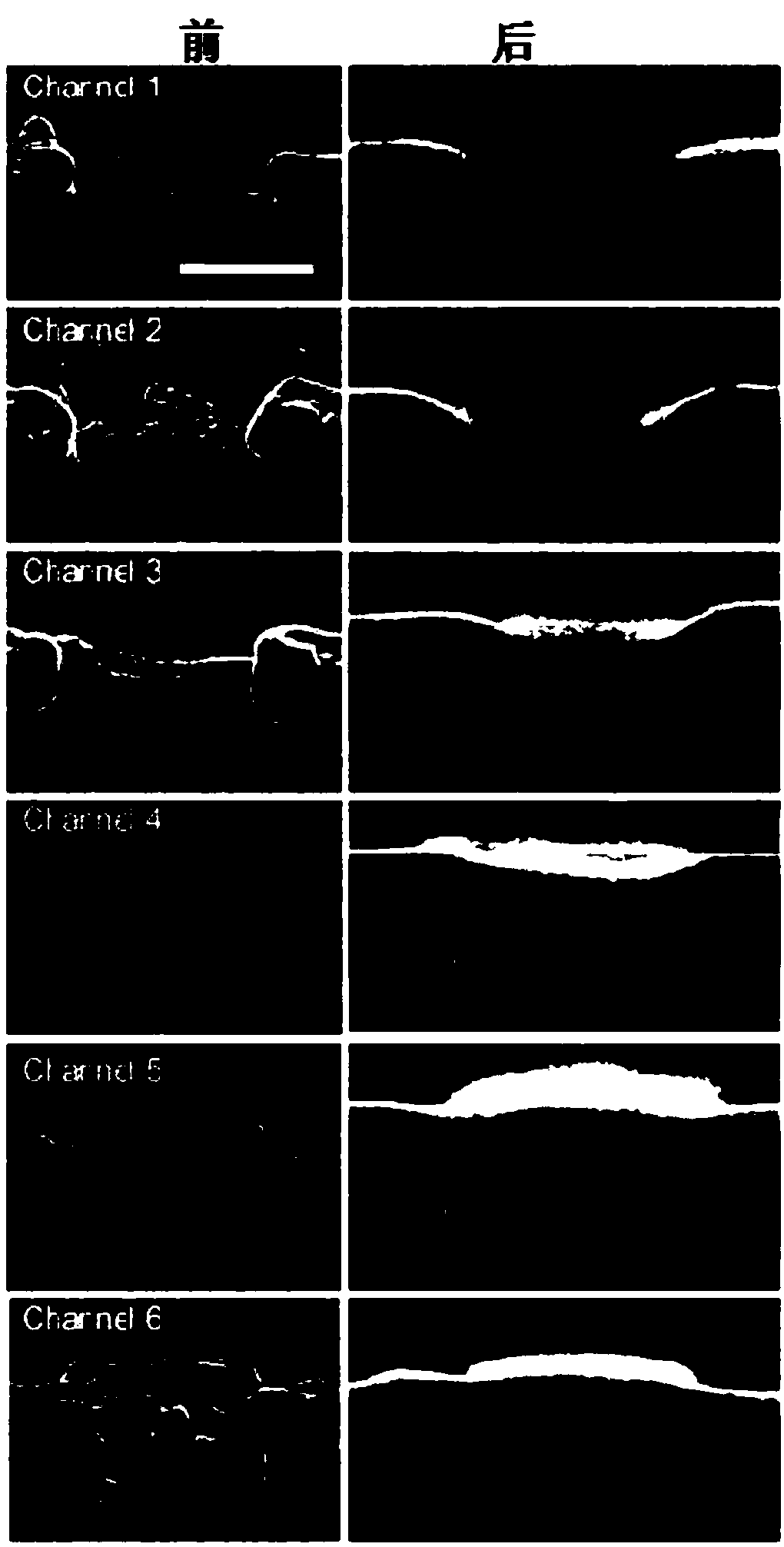

[0045] combine figure 2 , whi...

Embodiment 2

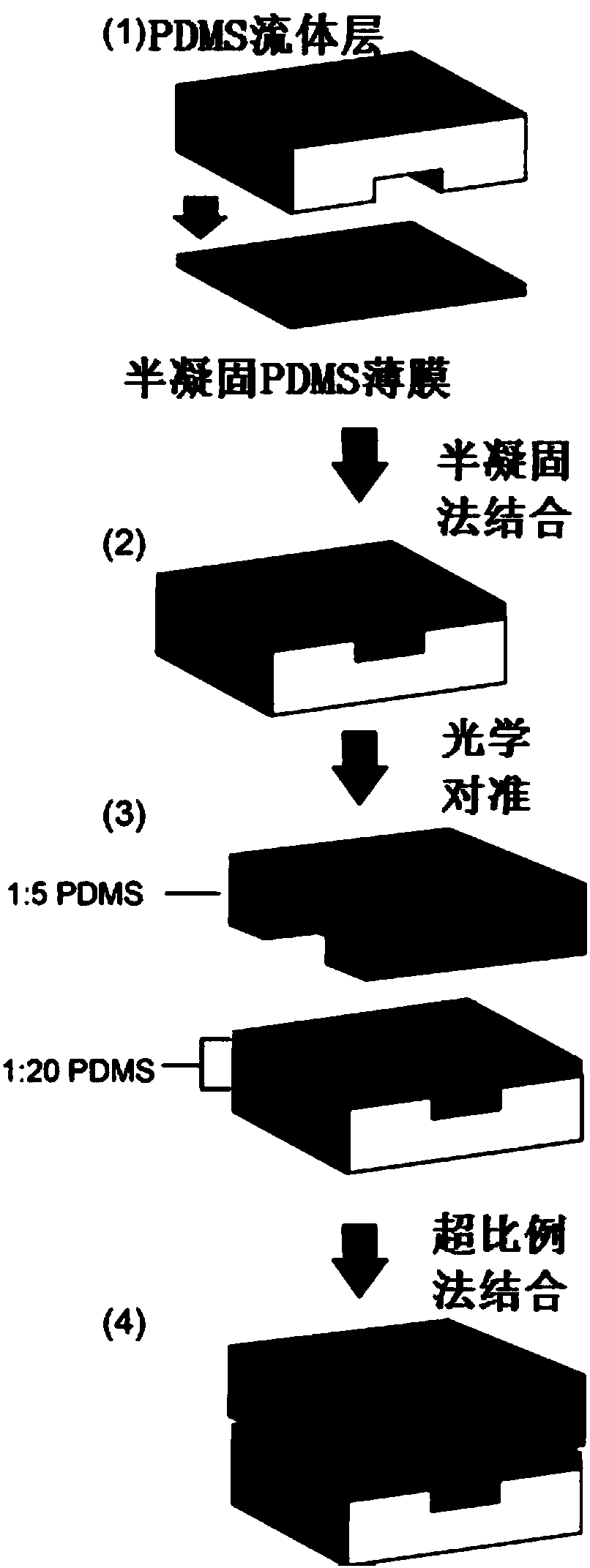

[0059] combine Figure 5 , which is a schematic diagram of the preparation process and application of the PDMS fluidic chip in step 2.

[0060] in Figure 5 (A) Fluid chip preparation process based on 3D printing and polishing technology: 1. Combining the semi-cured PDMS film layer with the fluid control layer; 2. Heating to 80°C for stable bonding; 3. Making different ratios of PDMS and curing agent 4. Using the super-proportional combination method to integrate the different layer structures of the fluid, and complete the chip preparation. Figure 5 (B) A fluid chip with four culture chambers with a diameter of 4.5 mm and a height of 1.5 mm fabricated using this technique. By controlling the switch of the entrance and exit of each culture chamber, different culture environments can be constructed in the 4 culture chambers, so as to carry out complex biological experiments on cell nucleus biological tissues. The related functions are demonstrated by using food coloring age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com