Drawing die applied to high-strength superfine steel wires

A technology of fine steel wire and die, applied in the direction of wire drawing die, etc., can solve the problems of increasing drawing resistance, excessive dry wear of steel wire and die paper, setting many edges and corners, etc., so as to reduce die wear, smooth drawing operation and prolong use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

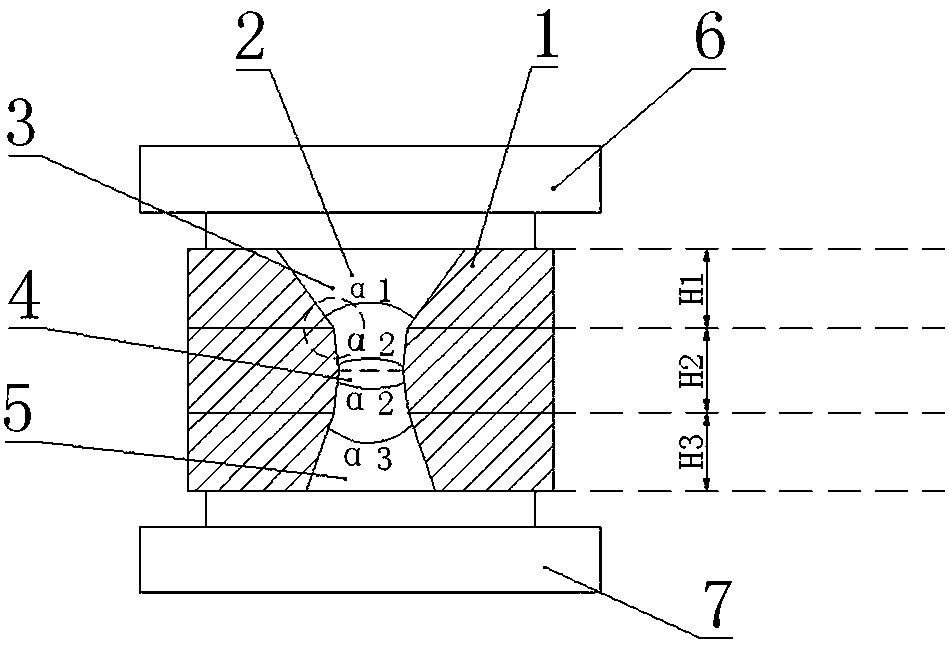

[0025] Such as figure 1 , figure 2 As shown, a drawing die suitable for high-strength ultra-fine steel wire, the drawing die includes a die body 1, and a through hole passing through the die body 1 is opened on the die body 1, the through hole is a drawing through hole 2, and the drawing The through hole 2 is funnel-shaped, and the diameter of the upper and lower parts is larger than that of the middle part.

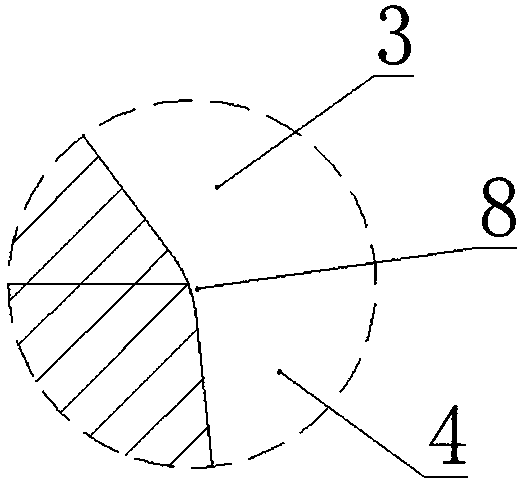

[0026] Such as figure 1 , figure 2 As shown, the hole structure of the drawn through hole 2 is sequentially from top to bottom the entrance area 3, the deformation and sizing area 4 and the exit area 5, the entrance area 3 and the de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com