Laser micro-hole machining cooperative control system and method based on industrial personal computer

A technology of collaborative control and micro-hole processing, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of low processing reliability, processing accuracy and processing efficiency difficult to meet processing requirements, etc., to ensure reliability and reliability. High efficiency, friendly human-computer interface, and high workpiece accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

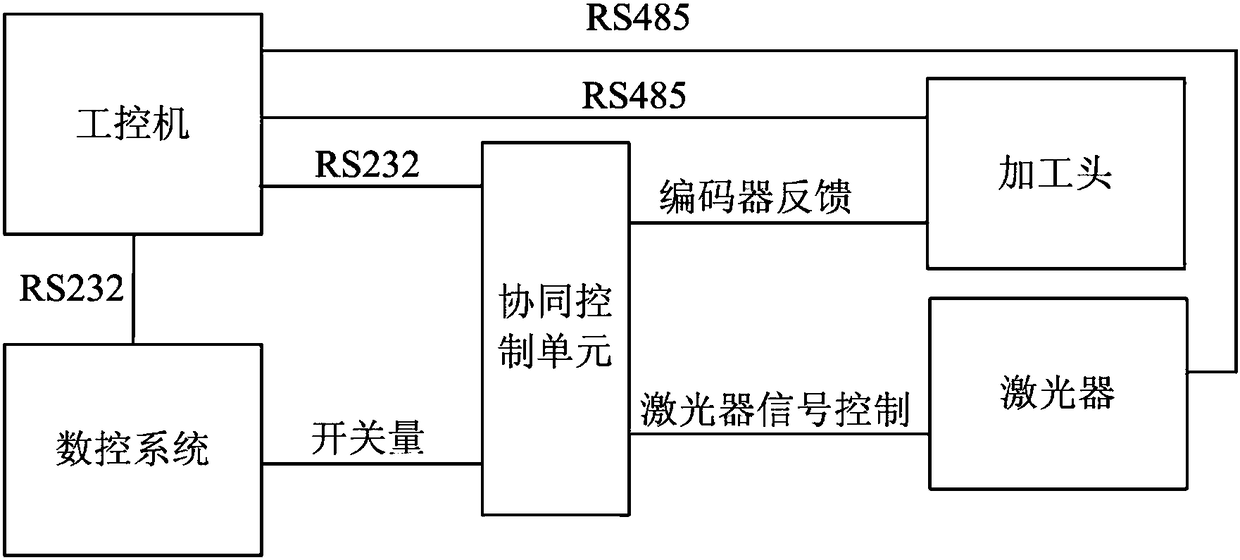

[0036] The structure of the control system of the present invention is as follows: figure 1 As shown, the system control structure is mainly composed of three parts, namely: industrial computer control part, numerical control system part, cooperative control unit part. The specific communication interaction of these three parts is as follows:

[0037] 1) The industrial computer is connected with the cooperative control unit and the numerical control system through the RS232 interface, and receives relevant state parameters from the cooperative control unit and transmits them to the numerical control system; at the same time, it reads the current operating parameters and status information of the processing head; controls the switch of the laser and receives Status information fed back by the laser;

[0038] 2) The industrial computer transmits the hole-making process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com