Numerical-control machine tool

A CNC machine tool, machine tool technology, applied in the direction of metal processing machinery parts, large fixed members, maintenance and safety accessories, etc., can solve the problems that affect the machine tool, useless, etc., achieve high processing accuracy, avoid the reduction of processing accuracy, and high precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

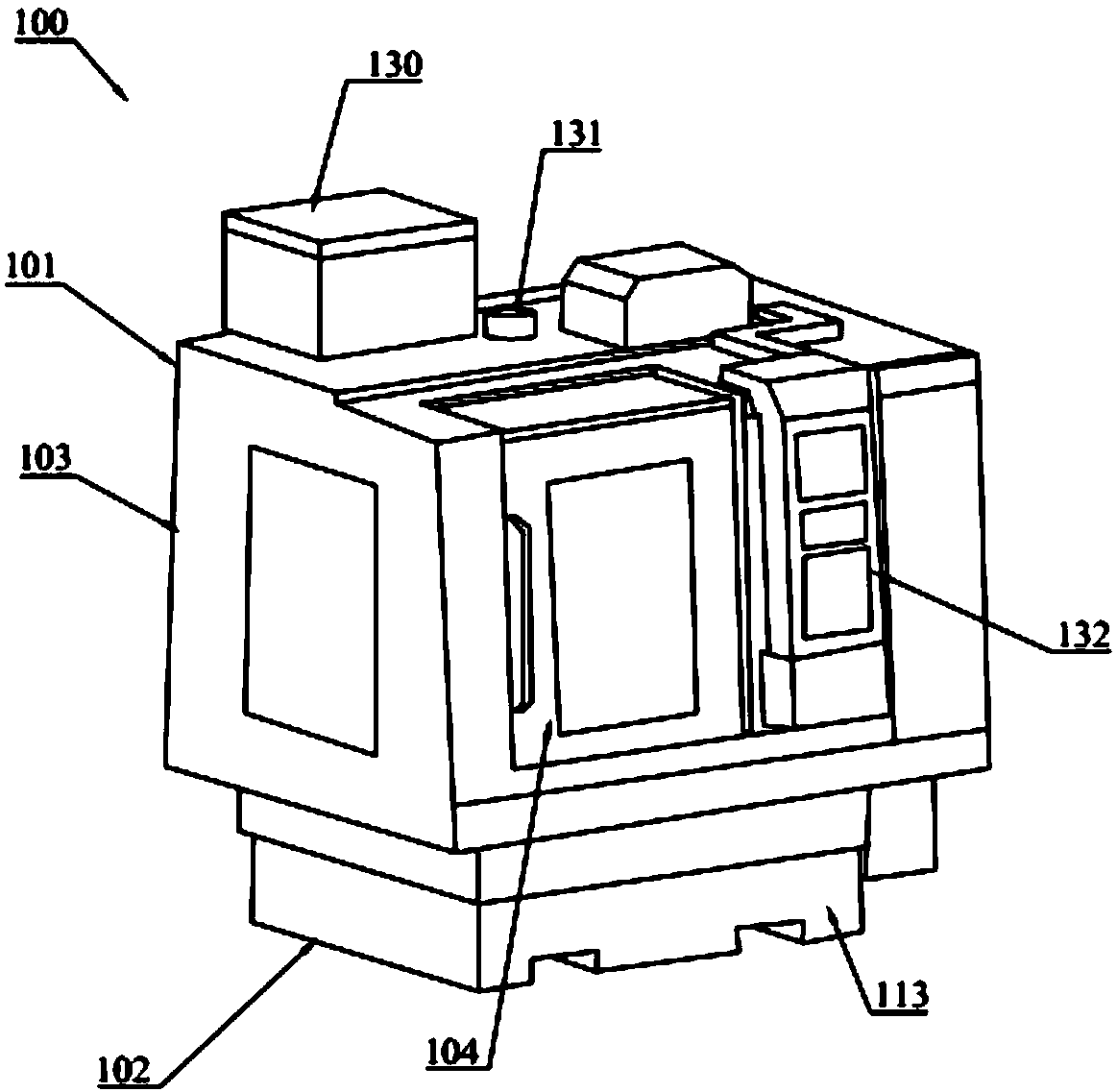

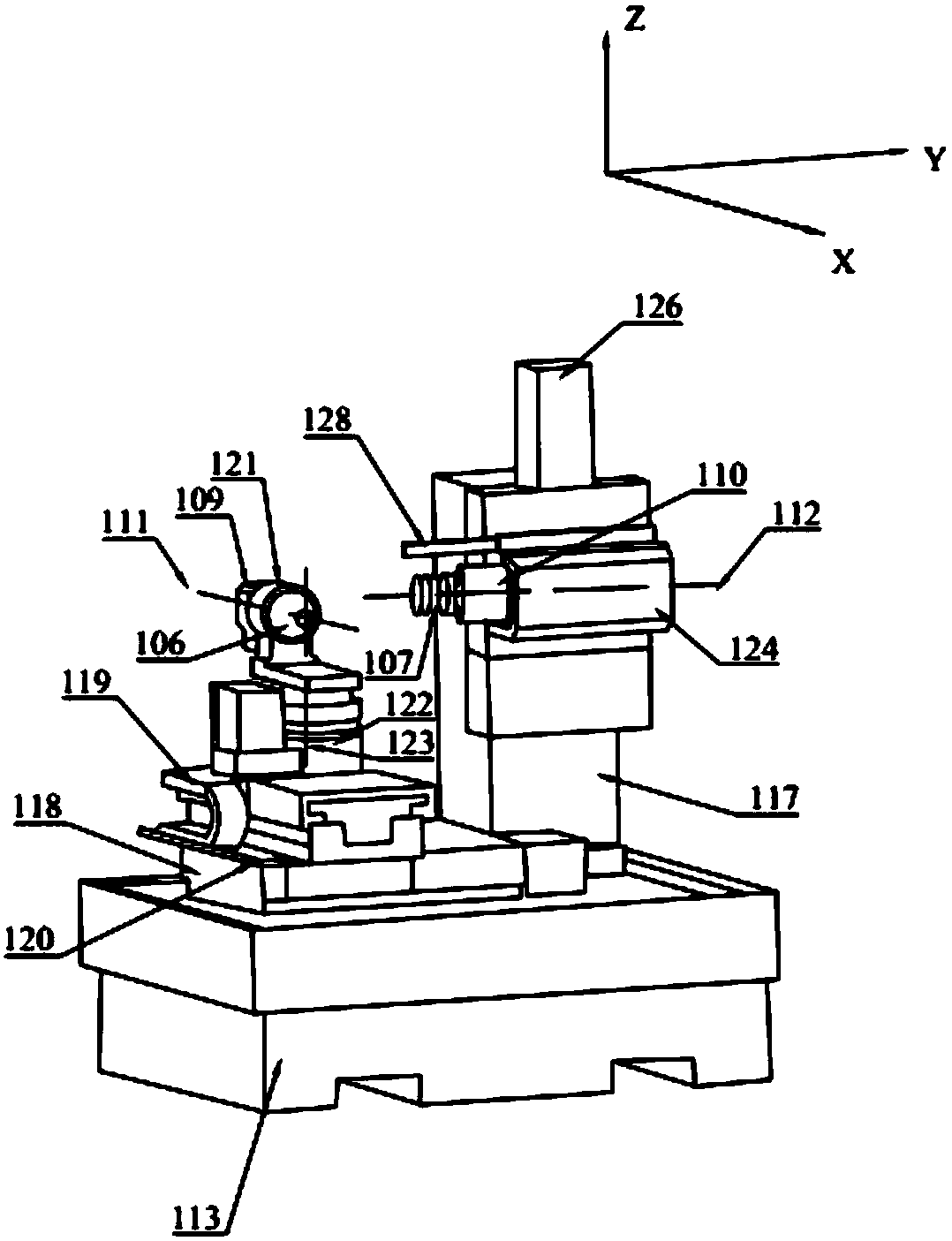

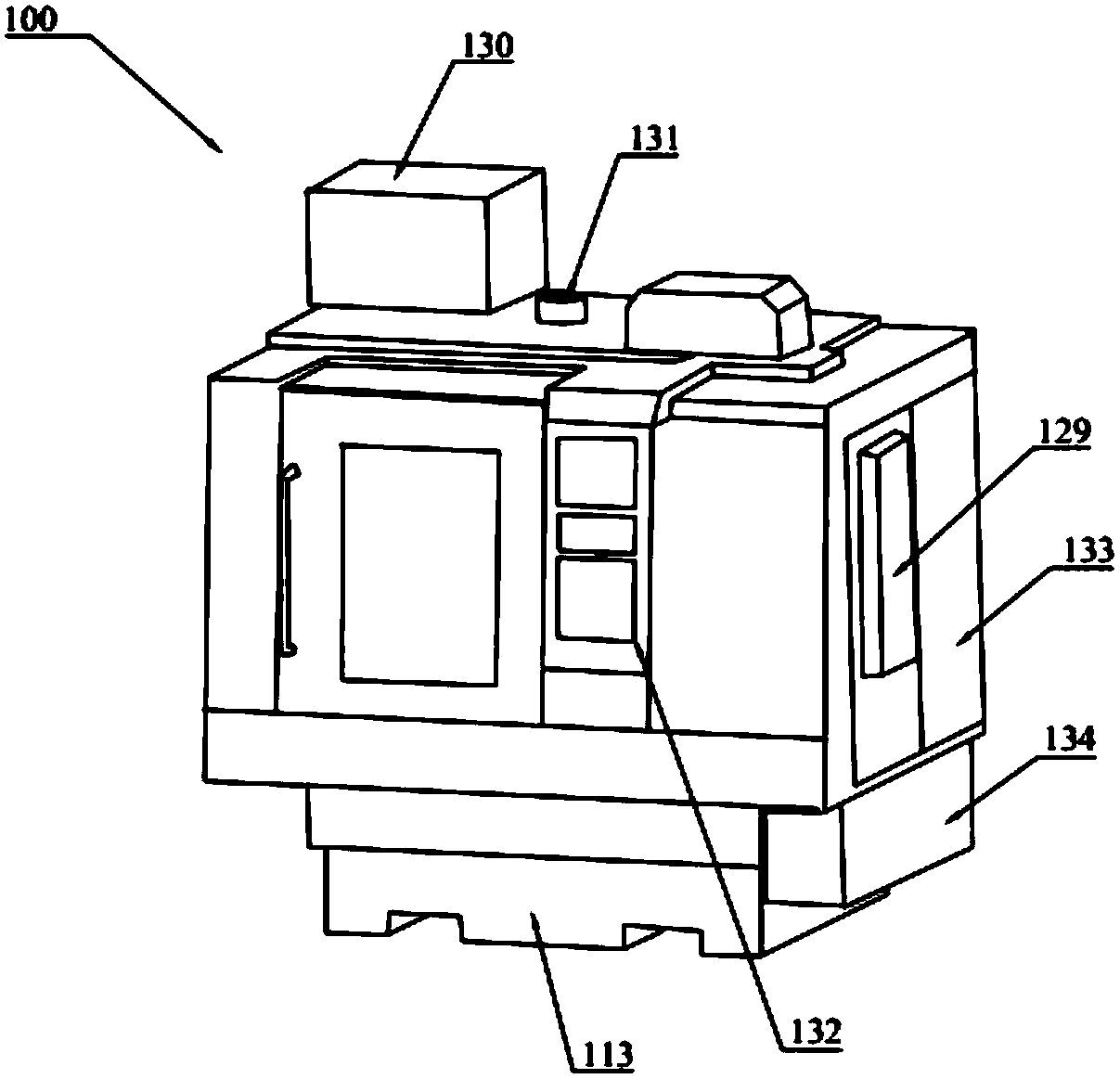

[0021] Such as Figure 1 to Figure 3 As shown, a numerically controlled machine tool 100 includes: a machine tool box 101 and a support member 102 supporting the machine tool box 101; the machine tool box 101 includes a box body 103 and an operating movable door 104; the operating movable door 104 is movably connected to the box body 103; the machine tool box 101 is provided with a working head and a motor that drives the movement of the working head; the supporting part 102 includes: a natural granite base 113, a natural granite column 117 and a natural granite carriage 118; the natural granite base 113 defines mutually perpendicular X-axis, Y Axis and Z axis; natural granite plank 118 is arranged on the top of natural granite base 113 and slides in the plane formed by X axis and Y axis relative to natural granite base 113; Natural grani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com