Surface oxygen vacancy ultrathin bismuth oxychloride nanosheet and preparation method thereof

A technology of bismuth oxychloride and surface oxygen, applied in chemical instruments and methods, inorganic chemistry, bismuth compounds, etc., can solve the problems of inability to form defects on the crystal surface, low utilization rate of visible light, small specific surface area, etc., and achieve low cost and excellent performance Photoelectrochemical activity, mild conditions and controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The invention provides a preparation method of ultra-thin bismuth oxychloride nanosheets with oxygen vacancies on the surface, comprising the following steps:

[0042] S1: Take bismuth nitrate pentahydrate, polyvinylpyrrolidone, mannitol, and water, and stir until the solution is clear and transparent;

[0043] S2: Add KCl solution to the mixed solution, and stir to obtain the first mixed system;

[0044] S3: Add triethylamine dropwise to the first mixed system, and stir to obtain the second mixed system;

[0045] S4: heating the second mixed system with water;

[0046] S5: After the second mixed system is cooled, centrifuge, remove the supernatant, and keep the precipitate;

[0047] S6: wash the precipitate with water first, and then with ethanol;

[0048] S7: put the washed precipitate in ethanol and sonicate;

[0049] S8: centrifuging and drying the precipitate to obtain ultrathin bismuth oxychloride nanosheets with oxygen vacancies on the surface.

[0050] As m...

Embodiment 1

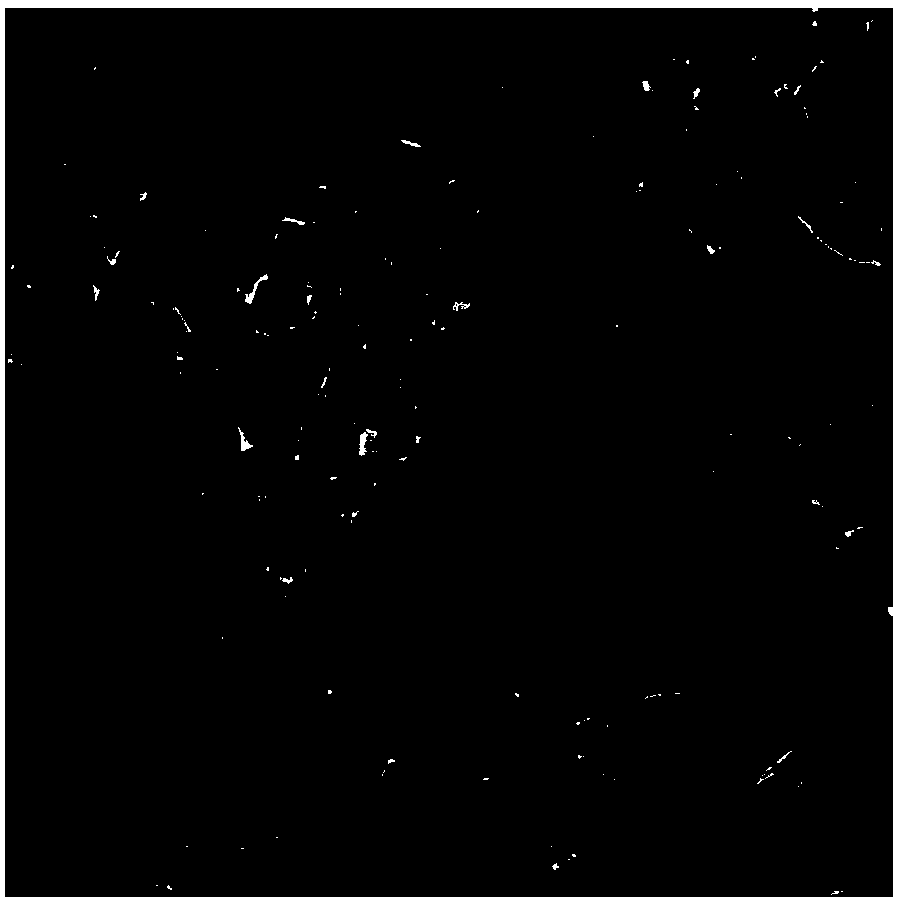

[0064] Add 0.4850g Bi(NO 3 ) 3 ·5H 2 0, 0.4000g polyvinylpyrrolidone, 0.4550g mannitol, be dissolved in 25mL deionized water, keep stirring, dissolve to obtain a clear and transparent solution; add 2mL saturated KCl solution dropwise to this mixed liquor solution, stop stirring after dropping 10min; The mixed solution was transferred to a hydrothermal reaction kettle so that the mixed solution reached 80% of the kettle volume, and then the system was hydrothermally treated at 160° C. for 3 hours. After the reaction kettle was cooled to room temperature, centrifuged to obtain a white sample, took the precipitate, washed the precipitate four times with deionized water (centrifuged at 10000rmp / min for 10min with a high-speed centrifuge), and finally dried it with a lyophilizer to obtain a thicker sample. BiOCl slab sample. The TEM image of the prepared BiOCl thick slices can be found in figure 1 .

Embodiment 2

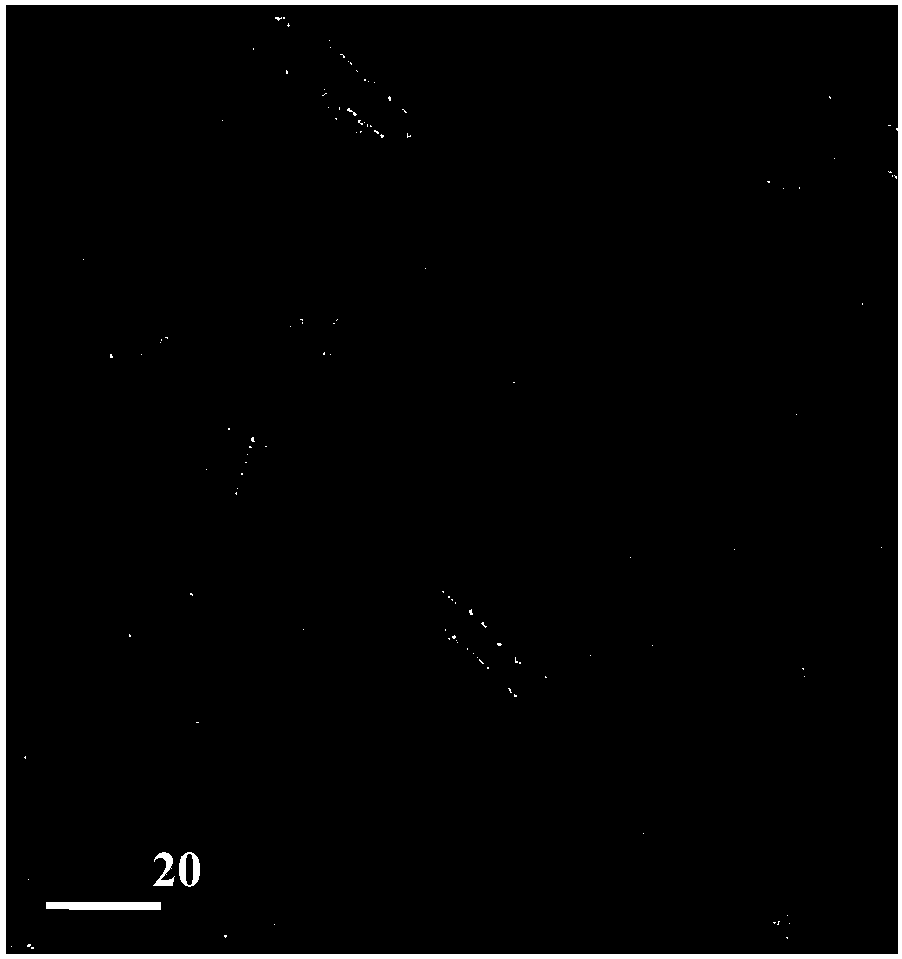

[0066] see figure 2 , add 0.4850g Bi(NO 3 ) 3 ·5H 2 0, 0.4000g polyvinylpyrrolidone, 0.4550g mannitol, be dissolved in 25mL deionized water, keep stirring, dissolve to obtain a clear and transparent solution; add 2mL saturated KCl solution dropwise to this mixed liquor solution, stop stirring after dropping 10min; The mixed solution was transferred to a hydrothermal reaction kettle so that the mixed solution reached 80% of the kettle volume, and then the system was hydrothermally reacted at 160° C. for 3 hours. After the reactor was cooled to room temperature, the obtained white sample was centrifuged and washed with deionized water for four times (centrifuged at a speed of 10000rmp / min for 10min in a high-speed centrifuge). The following intermittent ultrasound 5h. After ultrasonication, centrifuge at a speed of 500rmp / min for 10min in a low-speed centrifuge; take the centrifuge and centrifuge at a speed of 10000rmp / min for 10min in a high-speed centrifuge, and dry the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com