Oily sludge treatment machine

A processing machine and sludge technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of huge equipment investment, secondary air pollution, complicated operation, etc., and achieve high drying efficiency, easy operation and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

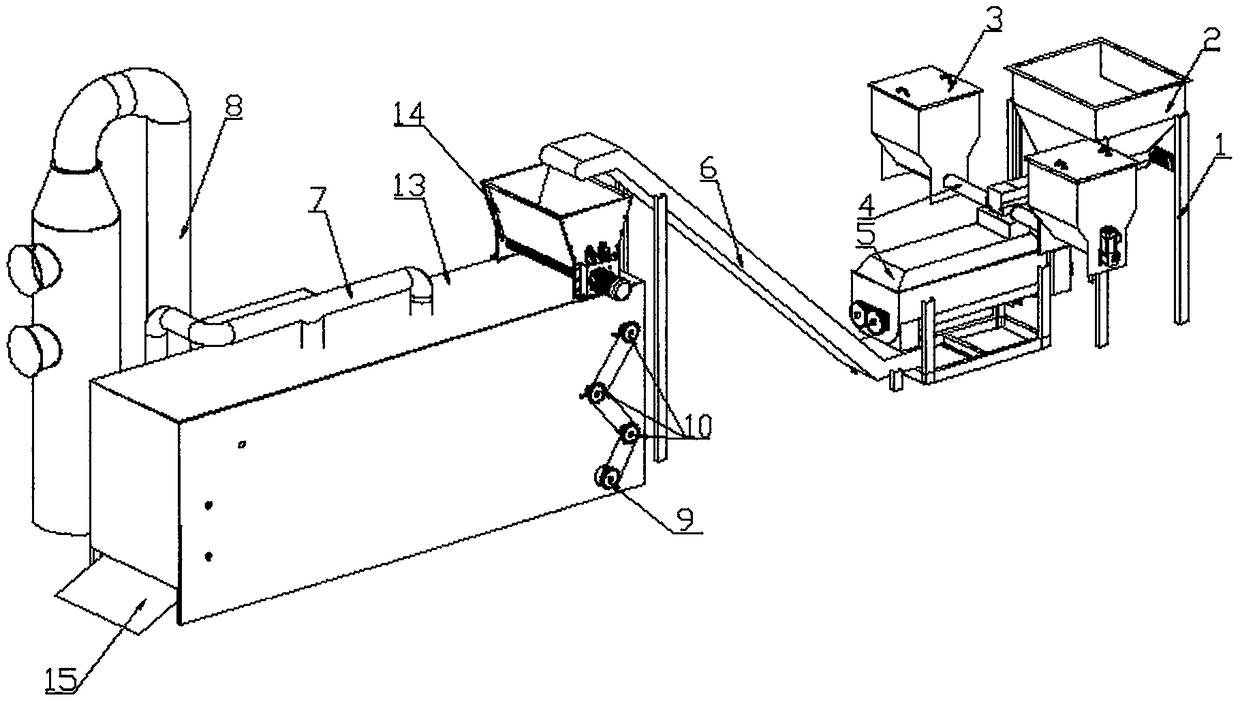

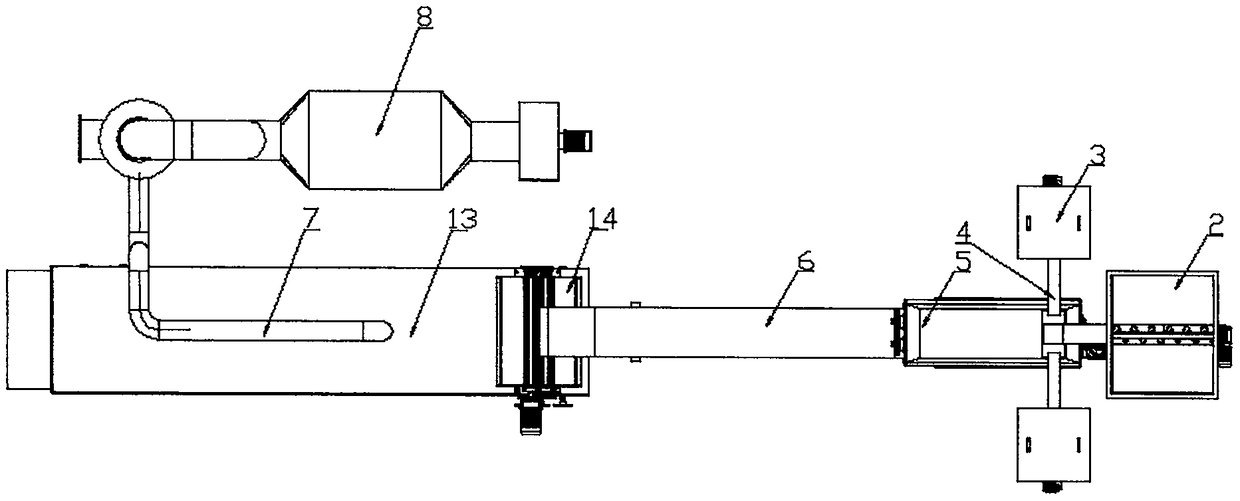

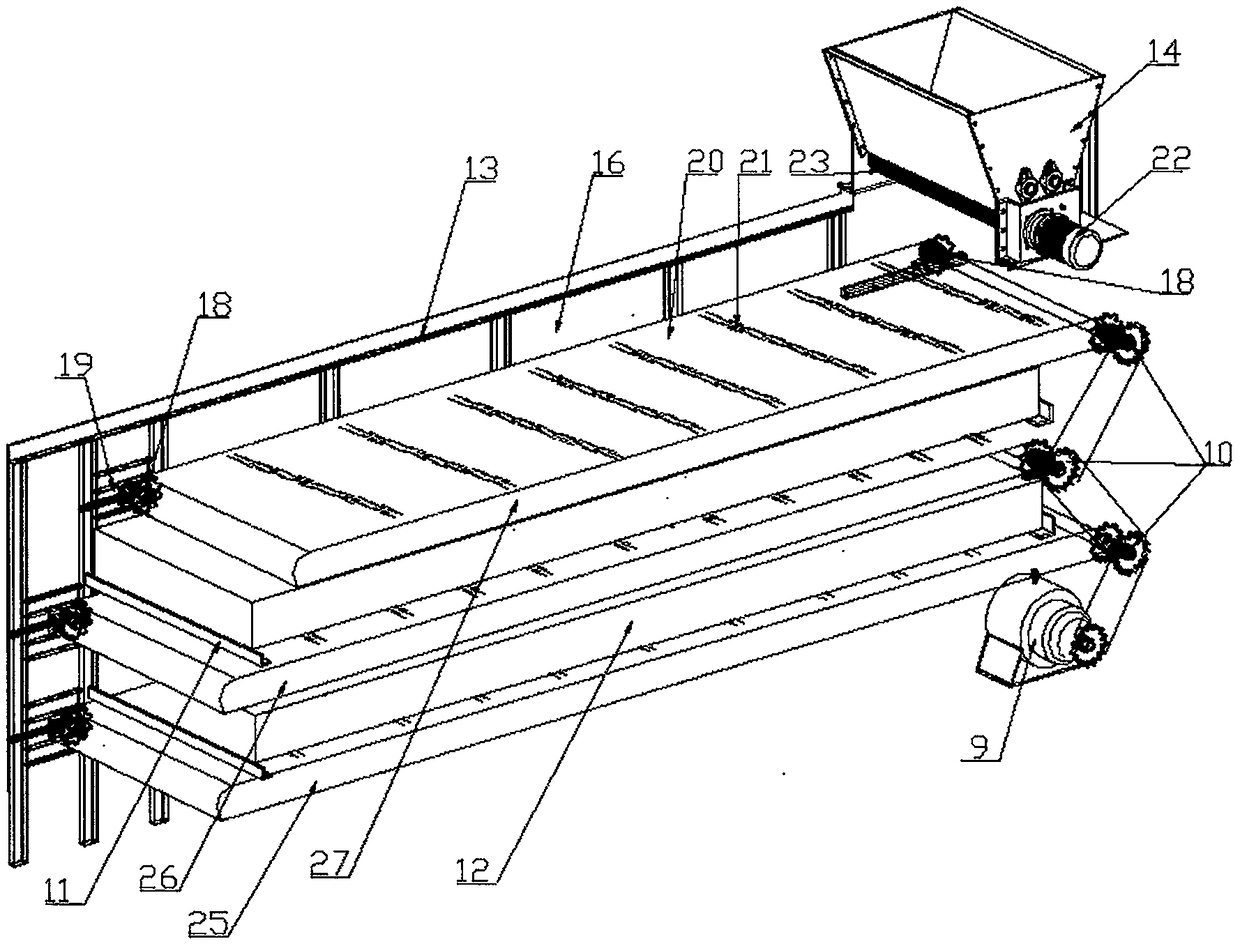

[0020] As shown in the figure, an oily sludge treatment machine includes a fixed frame 1, and the top of the fixed frame 1 is a sludge silo 2, and the inside of the sludge silo 2 is connected by an auger and an agitator 5. The described On the left side of the sludge silo 2 and on the front and rear sides of the mixer 5 are respectively provided an additive hopper 2, and the two additive hoppers 2 are respectively connected by the conveying auger 4 and the mixer 5, and the left bottom of the mixer 5 is It is connected with the conveyor belt hoist 6, and the conveyor belt hoist 6 is connected with the feed port of the sludge molding machine 14, and the sludge molding machine 14 pier is placed on the right end top of the sludge drying machine 13, and the sludge The top of the sludge dryer 13 is provided with at least two water vapor outlet pipes 7 to connect with the external waste gas treatment equipment 8 , and the bottom of the left end of the sludge dryer 13 is provided with ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap