Quartz tube automatic control feeding production method and device for semiconductor photovoltaics

A production method and technology of production equipment, applied in the field of quartz tube production, can solve the problems of partial wall of quartz tube, uneven pressure, uneven distribution of quartz sand raw materials, etc., and achieve the effect of improving light transmittance and qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

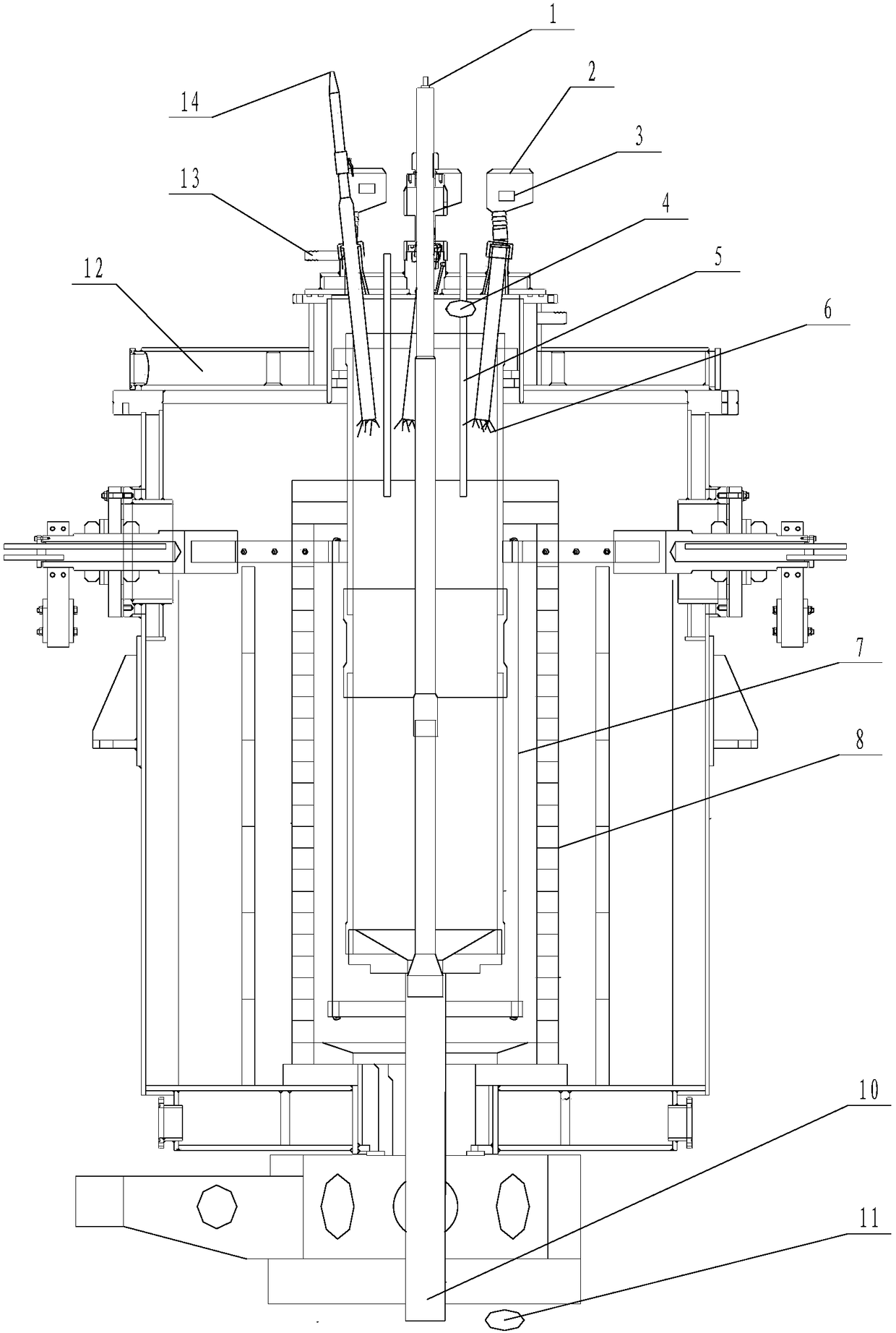

Image

Examples

Embodiment 1

[0027] The described production method of automatic control feeding of quartz tubes for semiconductor photovoltaics comprises the following steps:

[0028] (1) Quartz sand purification treatment:

[0029] After crushing the quartz sand, take the quartz sand particles with a D50 value of 150 μm. After washing the mud with water, the quartz sand and deionized water are prepared into a slurry at a mass ratio of 1:1.2.

[0030] Add sulfuric acid with a mass fraction of 15% to the slurry, stir and soak for 2 hours, then send the material to a filter press for dehydration, wherein the volume ratio of sulfuric acid to slurry is 1:0.8; the dehydrated quartz sand and Make slurry with deionized water according to the mass ratio of 1:1.8, adjust the slurry to neutral with ammonia water, then add 0.3% EDTA of quartz sand quality to the slurry, stir and mix for 1 hour, dehydrate, and rinse with deionized water to neutral and tumble dry.

[0031] Put the dried quartz sand into a chlorinat...

Embodiment 2

[0036] The described production method of automatic control feeding of quartz tubes for semiconductor photovoltaics comprises the following steps:

[0037] (1) Quartz sand purification treatment:

[0038] After crushing the quartz sand, take the quartz sand particles with a D50 value of 150 μm. After the mud is washed out with water, the quartz sand and deionized water are prepared into a slurry at a mass ratio of 1:1.5.

[0039] Adding sulfuric acid with a mass fraction of 22% in the slurry, stirring and soaking for 3 hours, the material is sent to a filter press for dehydration, wherein the volume ratio of sulfuric acid and slurry is 1:1.2; the dehydrated quartz sand and Make slurry with deionized water at a mass ratio of 1:2.2, adjust the slurry to neutral with ammonia water, then add 0.8% EDTA of quartz sand quality to the slurry, stir and mix for 2 hours, dehydrate, and rinse with deionized water to neutral and tumble dry.

[0040] Put the dried quartz sand into a chlor...

Embodiment 3

[0045] The described production method of automatic control feeding of quartz tubes for semiconductor photovoltaics comprises the following steps:

[0046] (1) Quartz sand purification treatment:

[0047] After the quartz sand is crushed, the quartz sand particles with a D50 value of 150 μm are taken. After the mud is washed out with water, the quartz sand and deionized water are made into a slurry at a mass ratio of 1:1.3.

[0048] Add sulfuric acid with a mass fraction of 18% to the slurry, stir and soak for 2.5 hours, then send the material to a filter press for dehydration, wherein the volume ratio of sulfuric acid and slurry is 1:1; the dehydrated quartz sand and Make slurry with deionized water at a mass ratio of 1:2, adjust the slurry to neutral with ammonia water, then add 0.5% EDTA of quartz sand mass to the slurry, stir and mix for 1.5 hours, dehydrate, and rinse with deionized water to neutral and tumble dry.

[0049] Put the dried quartz sand into a chlorination fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com