High molecular waste oiling recovery system

A technology for recycling system and waste, applied in the field of environment, can solve the problems of increased molecular weight distribution of thermal decomposition gas, poor thermal decomposition reaction of polymer waste, low oil recovery rate, etc. problems, the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

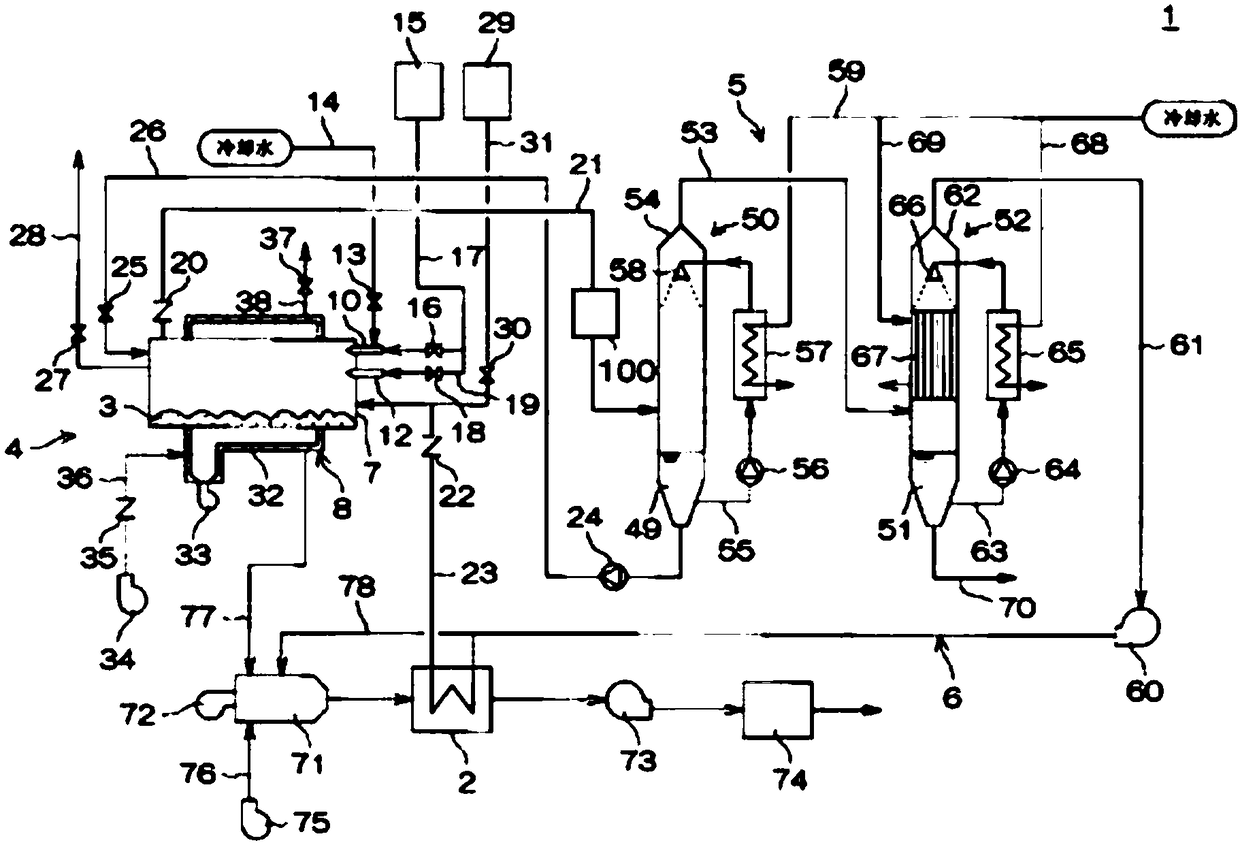

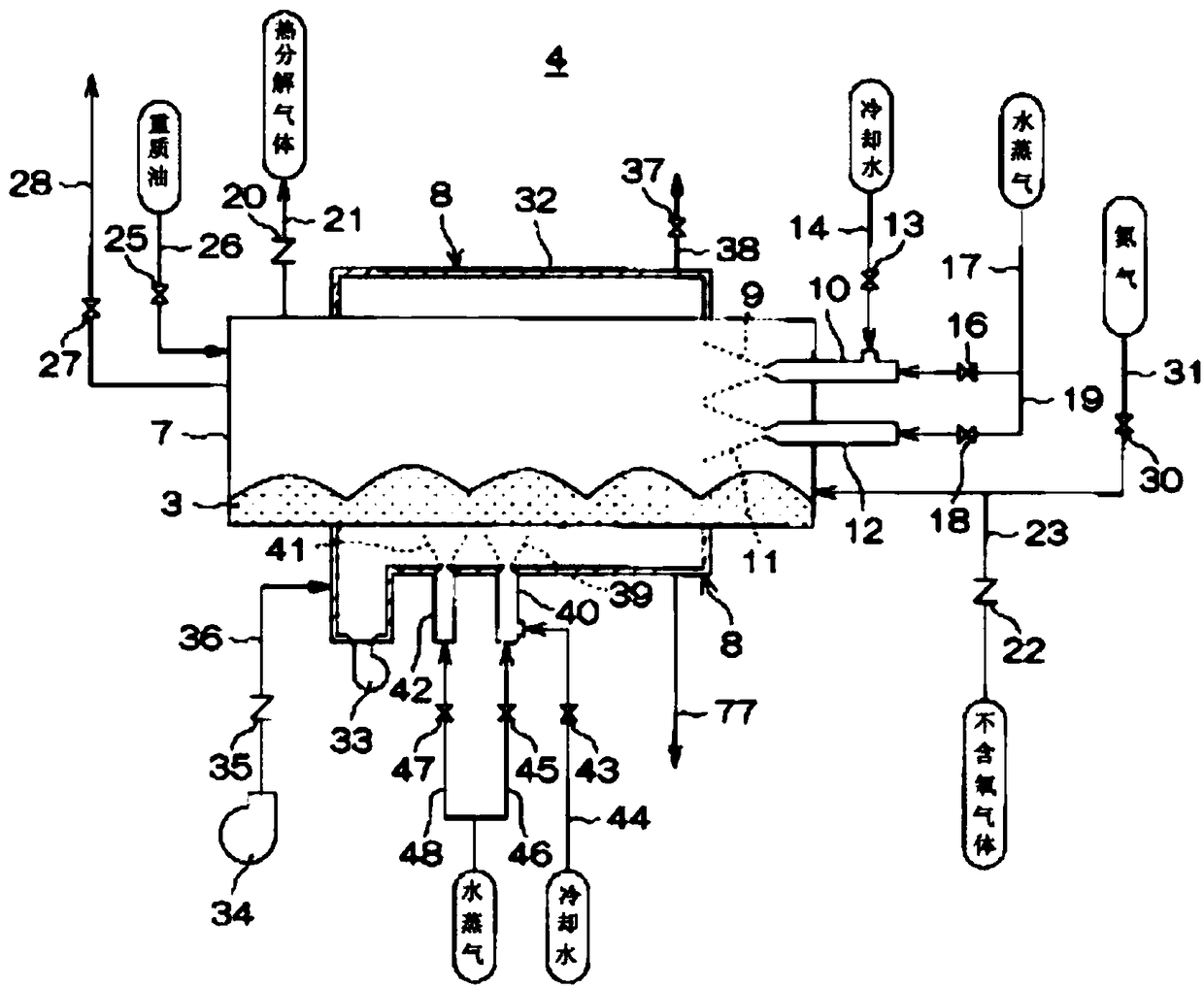

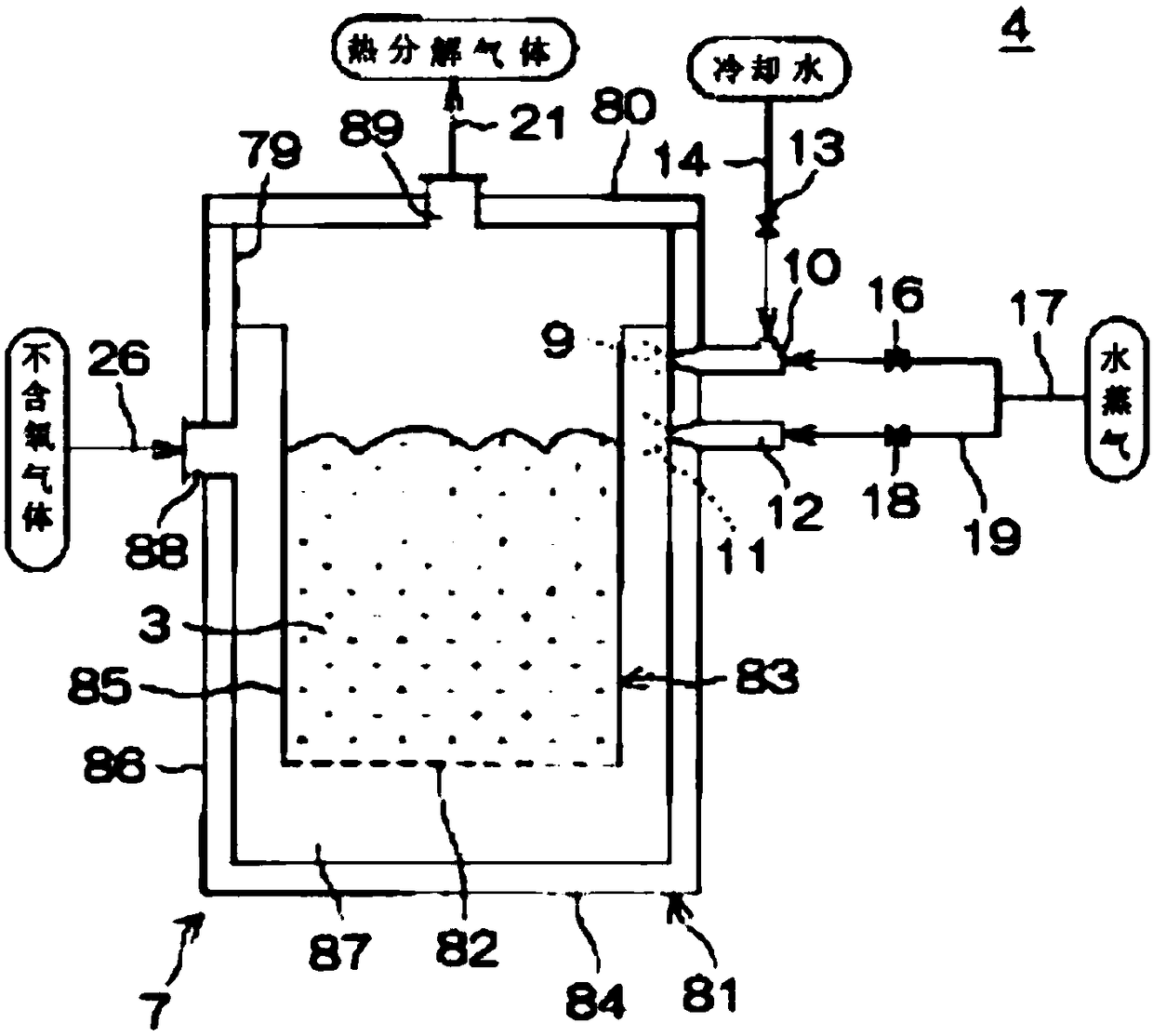

[0033] refer to Figure 1-Figure 4 , the system of the present invention has a heat exchanger 2 for heating the oxygen-free gas, and the polymer waste 3 is in direct contact with the oxygen-free gas heated by the heat exchanger 2 to perform thermal decomposition in an oxygen-free state A pyrolysis device 4 that generates pyrolysis gas, and an oil recovery device 5 that cools the pyrolysis gas generated in the pyrolysis device 4 and recovers condensed oil, and recovers the remaining oil after the oil recovery in the above-mentioned oil recovery device 5. The gas circulates through the circulation line 6 in the above-mentioned heat exchanger 2 as an oxygen-free gas.

[0034] The pyrolysis device 4 is provided with a pyrolysis furnace 7 for accommodating polymer waste 3, and has an external heating furnace 8 that surrounds the above-mentioned pyrolysis furnace 7 as an external heating device for heating, and is provided with a first cooling device ; the cooling device is when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com