Optical coding library, preparation method of carriers thereof, and application of optical coding library and carriers thereof

An optical encoding and carrier technology, applied in the field of suspension arrays, can solve problems such as limited encoding level, limited encoding capacity, and complicated steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

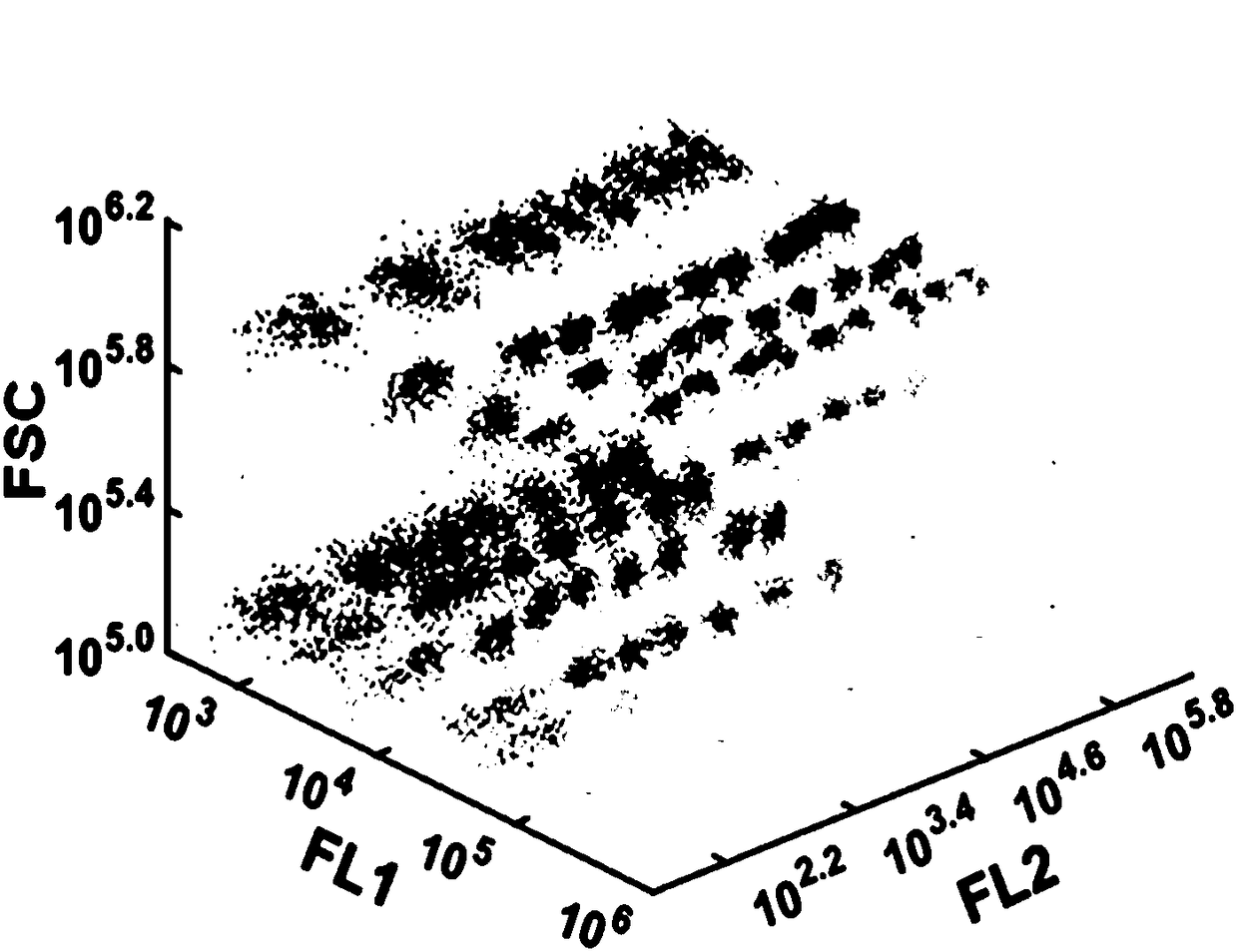

Image

Examples

preparation example Construction

[0083] 2. Preparation method of medium fluorescence intensity guest moiety (MF)

[0084] Step 1: ultrasonically dissolve 5.25 mg of fluorescein isothiocyanate (FITC) in 1 mL of absolute ethanol, stir magnetically at 300 rpm, add 73 μL of APTES, and react in the dark for 12 hours to obtain a FITC-APS solution.

[0085] Step 2: Take a three-necked flask, add 24.4mL of absolute ethanol, 1.6mL of ultrapure water and 1.3mL of 25% ammonia water in sequence, stir magnetically at 500rmp and add 100μL of the FITC-APS solution in step 1, react for 10min, then add 2.0mL of TEOS, React in a water bath at 40 degrees Celsius for 3 hours in the dark. After the reaction, centrifuge (10,000 rpm, 15 min) to discard the supernatant, wash once with ultrapure water, and redisperse the precipitate in 25 mL of water to obtain a FITC-CORE dispersion.

[0086] Step 3: Dilute 15mL of 25% ammonia water in 85mL of ultrapure water to make solution A, add 124.2mL of absolute ethanol and 25mL of the FITC-CO...

Embodiment 1

[0100] Example 1 (both 0.5 μm and 2.9 μm host moieties combined with 2-fold guest moieties):

[0101] 1. Using magnetic microspheres with a diameter of 0.5 μm as the core matrix (the first part), the main part of the quantum dot code is prepared according to the above-mentioned main part preparation steps by the improved layer-by-layer assembly method. Using different quantum dot concentrations and quantum dot assembly layers, the main part of the 2-fold fluorescent quantum dot code is obtained, that is, Z 1 =2.

[0102] Two kinds of guest moieties with different fluorescence intensities (which can be blank fluorescence intensity guest moieties and medium fluorescence intensity guest moieties) prepared by the guest moiety preparation method were mixed according to different ratios, and then assembled into 0.5 μm The surface of the body part. By regulating the mixing ratio of these two guest moieties, a combination of guest moieties with 2-fold FITC encoding is obtained, that...

Embodiment 2

[0106] Example 2 (both 2.9 μm and 6.2 μm host moieties combined with 3-fold guest moieties):

[0107] 1. Using magnetic microspheres with a diameter of 2.9 μm as the core matrix (the first part), the main part of the quantum dot code is prepared by the improved layer-by-layer assembly method according to the above-mentioned preparation steps of the main part. Using different quantum dot concentrations and quantum dot assembly layers, the main part of the 8-fold fluorescent quantum dot code is obtained, that is, Z 1 =8.

[0108] Three kinds of guest moieties with different fluorescence intensities (which can be a blank fluorescence intensity guest moiety, a medium fluorescence intensity guest moiety and a high fluorescence intensity guest moiety) prepared by the guest moiety preparation method are mixed according to different proportions of these three kinds of guest moieties, Then assemble to the surface of the main part of 2.9 μm. By regulating the mixing ratio of these thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com