Multi-pipe efficient easy-installing exhaust pipe structure

An exhaust pipe, easy-to-install technology, used in exhaust devices, mufflers, engine components, etc., can solve the problems of heat accumulation in the exhaust pipe, affecting the life of the exhaust pipe, environmental pollution, etc., to prolong the service life, prevent Heat build-up, the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

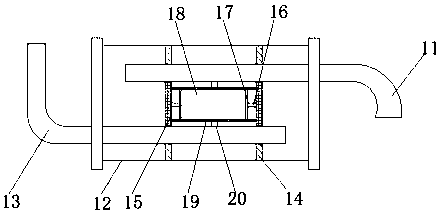

[0025] In Embodiment 1, when the device is in use, when the engine is running at a low speed, the temperature of the exhaust gas is relatively low, the volume change of the airbag 18 is small, and the gap between the first partition 14 and the second partition 15 is small. The back pressure will prevent the exhaust gas from rushing out, and the exhaust gas will return to the inside of the engine, so that the mixture can be completely burned, saving fuel, and reducing the burden on the exhaust gas purification device. When the engine is running at high speed, the temperature of the exhaust gas is relatively high. The volume of the airbag 18 changes greatly, and the first partition 14 is separated from the second partition 15. At this time, the waste gas can be smoothly discharged from the device, preventing heat accumulation inside the device and prolonging the service life of the device.

Embodiment 2

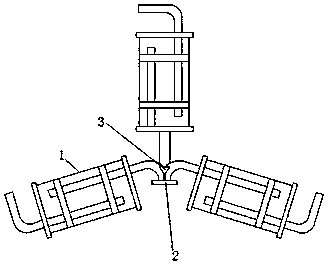

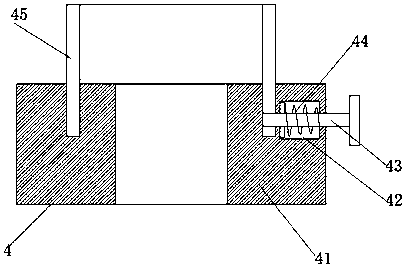

[0026] In Embodiment 2, when the device is installed, it is connected to the engine through the anti-loosening nut 4 on the triangular flange 2, and then connected to the bracket through the hanging piece 20. The installation is convenient and simple, and the anti-loosening nut 4 can prevent it from being connected to the device. The screw falls off, which avoids the frequent vibration of the device and causes the screw to fall off, and improves the durability of the device. The reinforcement plate 3 can strengthen the strength of the device itself. When the screw is connected to the anti-loosening nut 4, pull the adjustment lever first The handle on the 43 takes out the baffle plate 45, and after the screw is screwed, install the baffle plate 45, and the adjusting rod fixes the baffle plate 45 under the action of the second spring 44, and the baffle plate 45 limits the rotation of the screw to prevent the screw fall off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com