Method for preparing porous titanium-base composite material through composite ultrasonic vibration high-pressure twisting

A technology of high-pressure torsion and composite materials, applied in medical science, prosthesis, tissue regeneration, etc., can solve the problem of reducing the strength of titanium, bio-affinity and corrosion resistance, which cannot be widely used in clinical medicine, and the pore size and shape cannot be obtained. Control and other issues, achieve good antibacterial and antivirus performance, good renewable performance, and improve biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

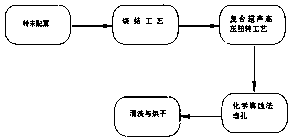

[0035] 1. Powder configuration: (the mass ratio of magnesium, silver, silicon, and phosphorus is (12-16): (0.8-1.4): (25-30): (0.5-1.3), and the rest is metal titanium, determine the single The amount of powder in the second twisting process is 20-500g.) The mass ratio of metal titanium powder, magnesium powder, silver powder, silicon powder and phosphorus powder with content greater than 99.99% is selected as 55:15:1:25:1, and the single The mass of the powder mixture during twisting is 500 g.

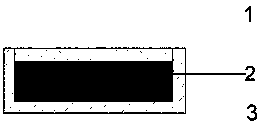

[0036] 2. Sintering stage: Extrude the configured mixed powder through a mold on a press to make a rough blank with a certain strength and density; The matrix composite materials are further connected and welded, and the blanks are batch-processed into disc-shaped samples of d8mm×0.5mm; one sample is put into a bag.

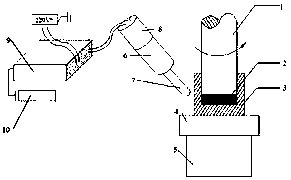

[0037] 3. Composite ultrasonic high-pressure torsion process: the initial ultrasonic-assisted torsion process, the powder mixture 2 prepared in the process of 2 with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com