Method for performing single molecule force spectrum test in gas phase environment

A single-molecule force spectroscopy, environmental technology, applied in the field of single-molecule force spectroscopy, can solve the problem of polymer single-chain properties, mechanical response behavior and kinetic parameters. High-performance polymer materials, single-molecule force spectroscopy application range and significance Restrictions and other problems, to achieve the effect of improving sensitivity and accuracy, convenient operation, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

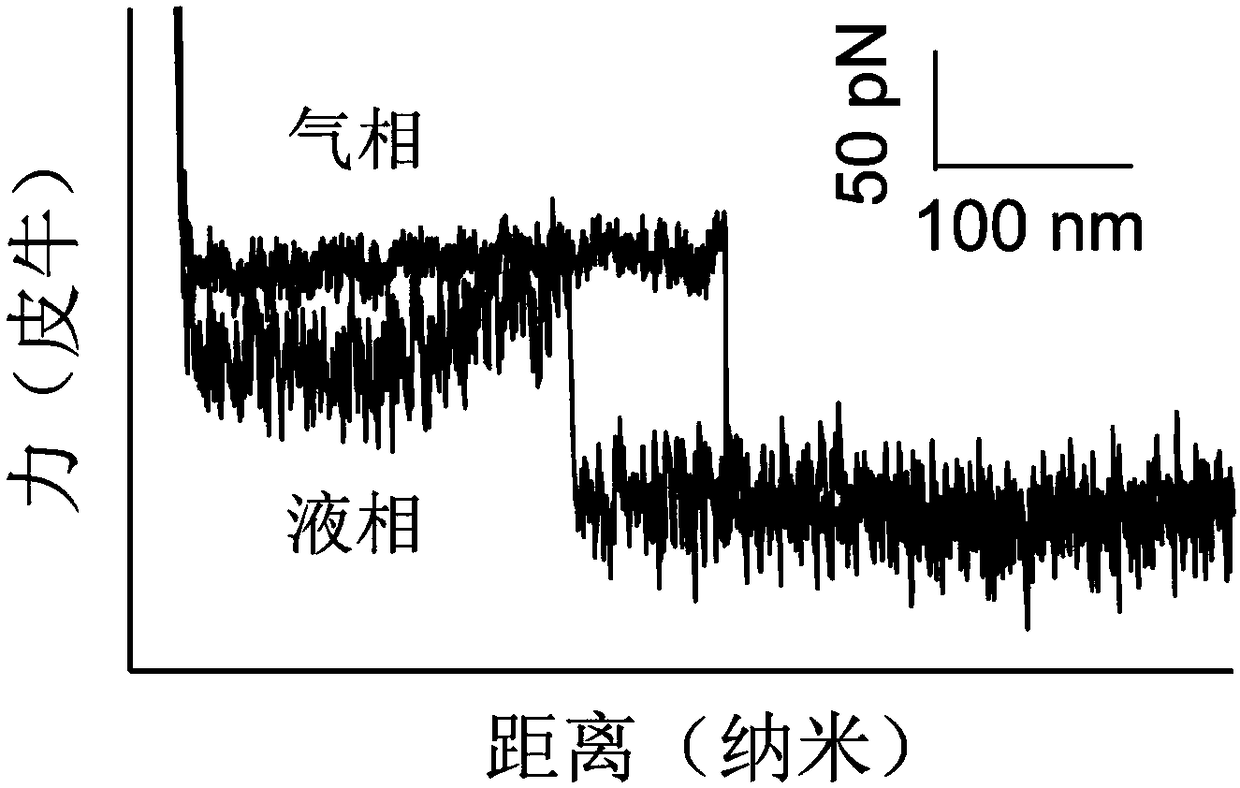

[0058] Example 1 Study on force-induced melting and melting of polyoxyethylene single crystal

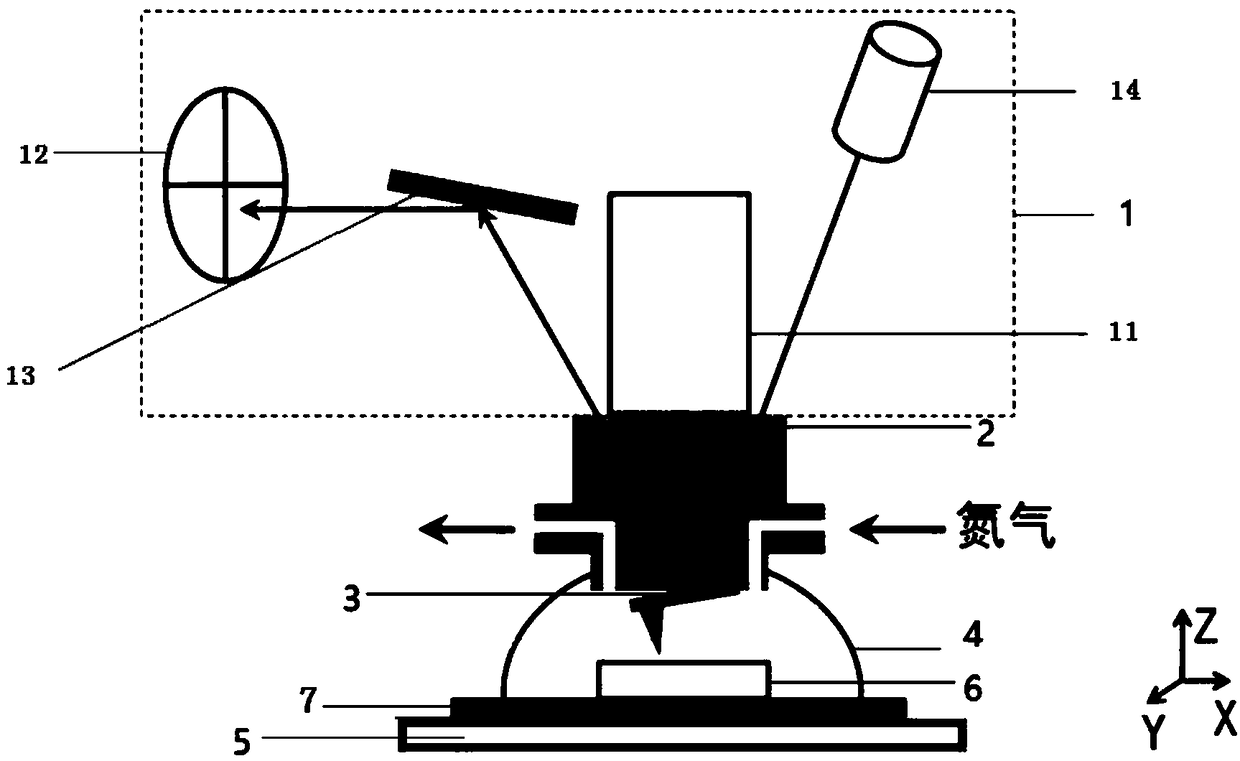

[0059] Sample 6 is a polyoxyethylene (PEO) single crystal obtained from the seed crystal method in the solution phase, the substrate 7 is an amide silicon substrate, and sample 6 is adsorbed on the substrate 7 by physical action; the elastic coefficient of AFM probe 3 is 0.2N / m; the material of the rubber cover 4 is fluorine rubber; the gas is nitrogen; the relative humidity is 11%.

[0060] The test process is as follows: the substrate 7 carrying the sample 6 is placed on the stage 5, and the position of the sample 6 is determined through the imaging mode of the atomic force microscope, such as figure 2 As shown, the atomic force microscope is then switched to the force spectrum mode, and the AFM probe 3 approaches the substrate 7 at a rate of 20nm / s-100μm / s. 3 contacts with PEO molecules to form a bridging structure, and then the scanner 11 shrinks, making the AFM probe 3 move ...

Embodiment 2

[0062] The research of single-chain motion in embodiment 2 polystyrene condensed matter

[0063] Sample 6 is a polystyrene (PS) ultra-thin film prepared on a hydroxylated silicon substrate by spin coating; the elastic coefficient of the AFM probe 3 is 0.02N / m~0.7N / m; the material of the rubber cover 4 is fluororubber; The gas introduced is nitrogen; the relative humidity is 11% to 40%.

[0064] The test process is as follows: first, then place the substrate 7 carrying the sample 6 on the stage 5, switch the atomic force microscope to the force spectrum mode, and drive the AFM probe 3 to move through the extension of the scanner 11, so that the AFM probe 3 moves at a distance of 2 μm The rate of / s approaches the substrate 7, and after contacting the substrate 7, stay for 3s with a downward pressure of 10nN, so that the AFM probe 3 contacts with the PS molecule to form a bridge structure, and then the scanner 11 shrinks, so that the AFM probe 3 moves at a speed of 2 μm / The sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic coefficient | aaaaa | aaaaa |

| Elastic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com