Electrode-free bismuth telluride thermoelectric device and preparation method thereof

A thermoelectric device, bismuth telluride technology, which is applied in the manufacture/processing of thermoelectric devices, and the material of thermoelectric device junction lead wires, etc., can solve the problems of complex and difficult electrode preparation, and achieves overcoming the complex preparation process and good thermal stability. , the effect of shortening the preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

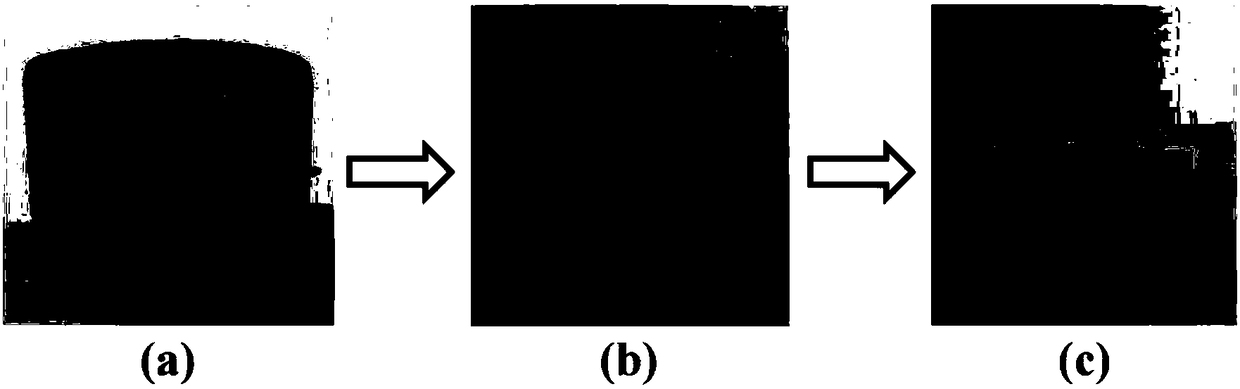

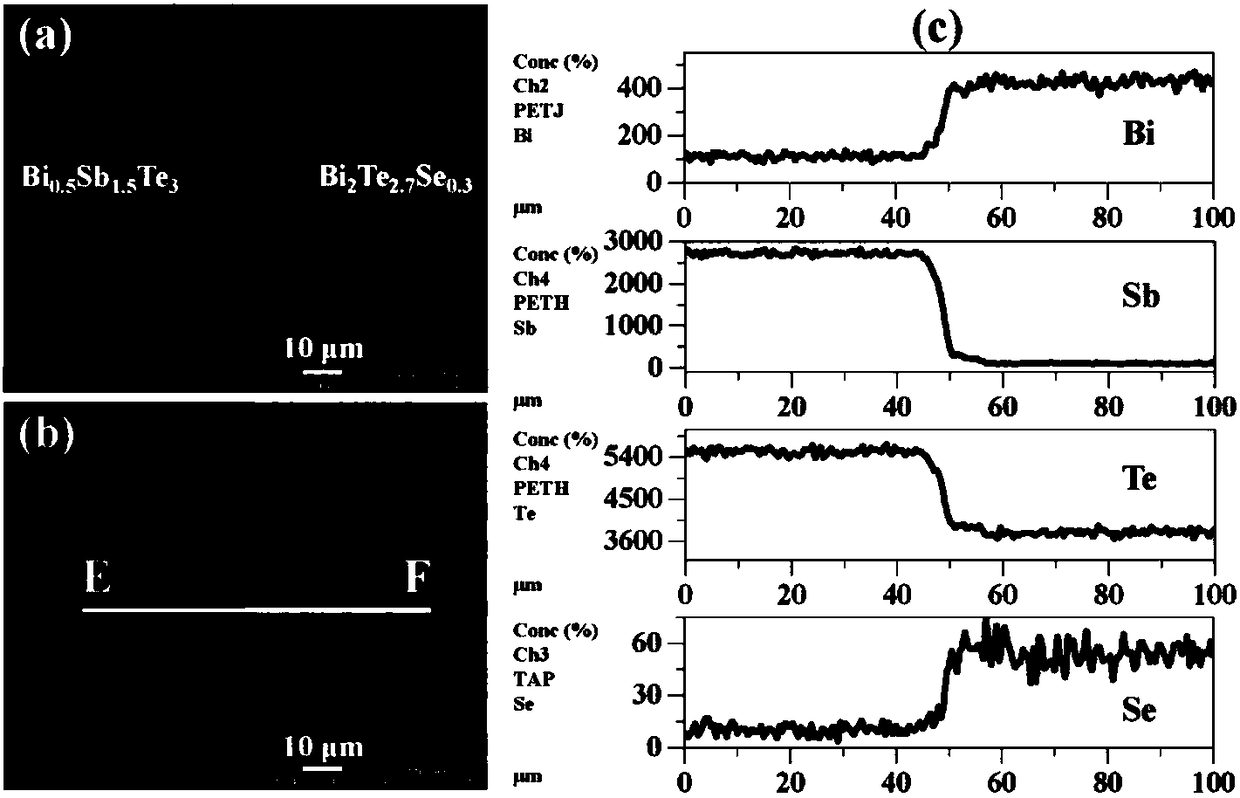

Image

Examples

Embodiment 1

[0044] A bismuth telluride thermoelectric device without electrodes and a preparation method thereof, comprising the following steps:

[0045] 1) Preparation of bismuth telluride alloy powder by melting method:

[0046] (1) Composed as Bi by name 0.5 Sb 1.5 Te 3 The stoichiometric ratio of Bi powder (purity 99.999%) 3.2755g, Sb powder (purity 99.999%) 5.7248g and Te powder (purity 99.999%) 11.9998g were accurately weighed, evenly mixed and sealed in a vacuum less than 10 -1 In a quartz tube of MPa;

[0047] (2) Similarly, the nominal composition becomes Bi 2 Te 2.7 Se 0.3 The stoichiometric ratio of Bi powder (purity 99.999%) 11.1645g, Te powder (purity 99.999%) 9.2029g and Se powder (purity 99.999%) 0.6328g are accurately weighed, evenly mixed and sealed in a vacuum less than 10 -1 In a quartz tube of MPa;

[0048] (3) The above-mentioned quartz tube is placed in a melting furnace, raised from room temperature to 900°C at a heating rate of 3°C / min, melted for 5 hours,...

Embodiment 2

[0063] 1) Preparation of bismuth telluride alloy powder by melting method:

[0064] (1) Composed as Bi by name 0.5 Sb 1.5 Te 3 The stoichiometric ratio of Bi powder (purity 99.999%) 4.8353g, Sb powder (purity 99.999%) 8.4509g and Te powder (purity 99.999%) 17.7141g were accurately weighed, evenly mixed and sealed in a vacuum less than 10 -1 In a quartz tube of MPa;

[0065] (2) Similarly, the nominal composition becomes Bi 2 Te 2.7 Se 0.3 The stoichiometric ratio of Bi powder (purity 99.999%) 16.4811g, Te powder (purity 99.999%) 13.5852g and Se powder (purity 99.999%) 0.9341g are accurately weighed, evenly mixed and sealed in a vacuum less than 10 -1 In a quartz tube of MPa;

[0066] (3) The above-mentioned quartz tube is placed in a melting furnace, raised from room temperature to 800°C at a heating rate of 3°C / min, melted in vacuum for 10 hours, and quenched in oil to obtain p-type Bi 0.5 Sb 1.5 Te 3 and n-type Bi 2 Te 2.7 Se 0.3 Quenched castings of alloys;

[0...

Embodiment 3

[0082] A bismuth telluride thermoelectric device without electrodes and a preparation method thereof, comprising the following steps:

[0083] 1) Preparation of bismuth telluride alloy powder by melting method:

[0084] (1) Composed as Bi by name 0.5 Sb 1.5 Te 3 The stoichiometric ratio of Bi powder (purity 99.999%) 4.8353g, Sb powder (purity 99.999%) 8.4509g and Te powder (purity 99.999%) 17.7141g were accurately weighed, evenly mixed and sealed in a vacuum less than 10 -1 In a quartz tube of MPa;

[0085] (2) Similarly, the nominal composition becomes Bi 2 Te 2.7 Se 0.3 The stoichiometric ratio of Bi powder (purity 99.999%) 16.4811g, Te powder (purity 99.999%) 13.5852g and Se powder (purity 99.999%) 0.9341g are accurately weighed, evenly mixed and sealed in a vacuum less than 10 -1 In a quartz tube of MPa;

[0086] (3) The above-mentioned quartz tube is placed in a melting furnace, raised from room temperature to 900°C at a rate of 1°C / min, melted in vacuum for 5 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com