Special ultrasonic 3D (Three Dimensional) printing equipment for artificial trachea and compound processing technology

An artificial trachea and 3D printing technology, applied in the directions of processing and manufacturing, additive processing, application, etc., can solve the problems of limiting the clinical application of artificial trachea, local infection, anastomotic dehiscence, etc. The effect of low cost and high printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

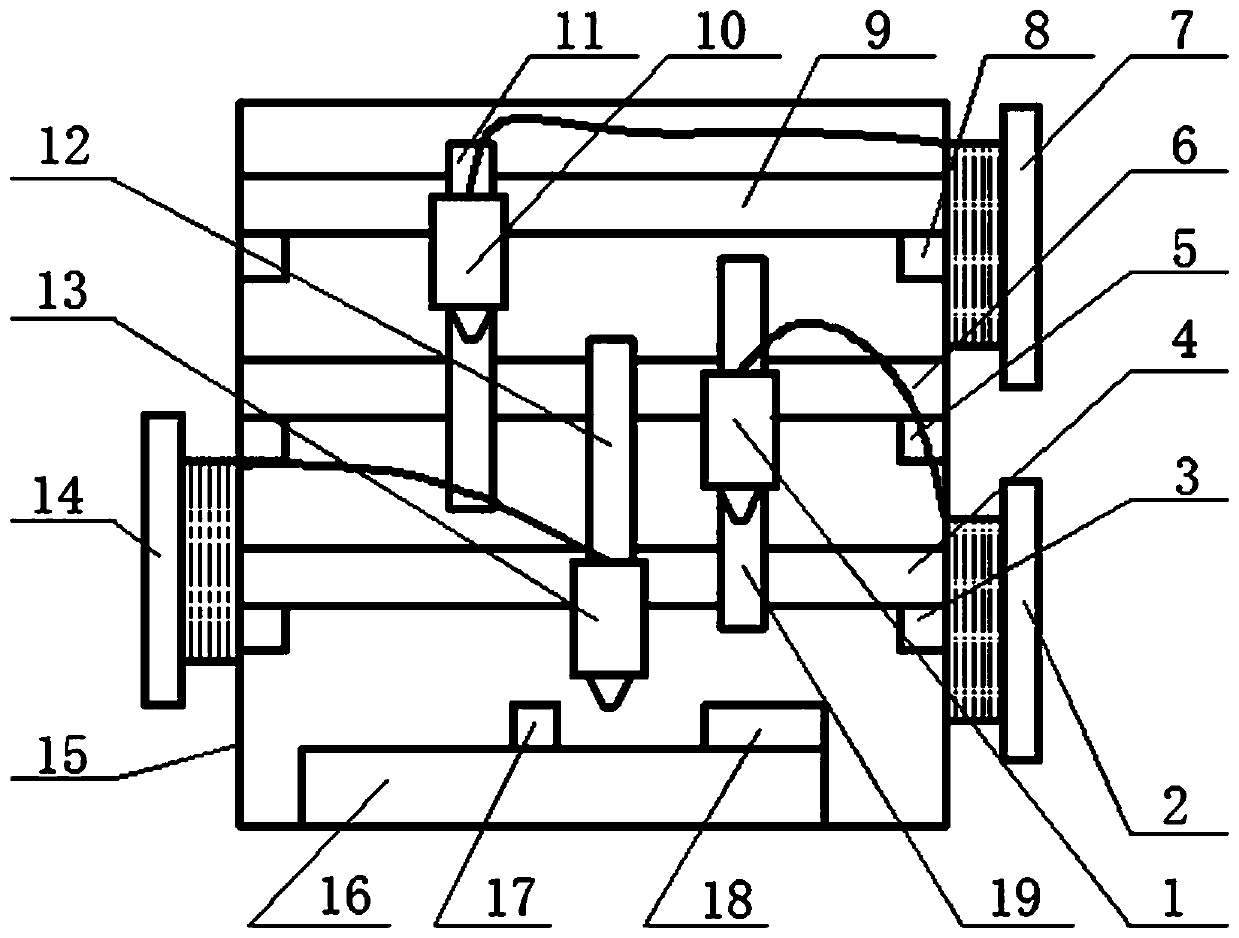

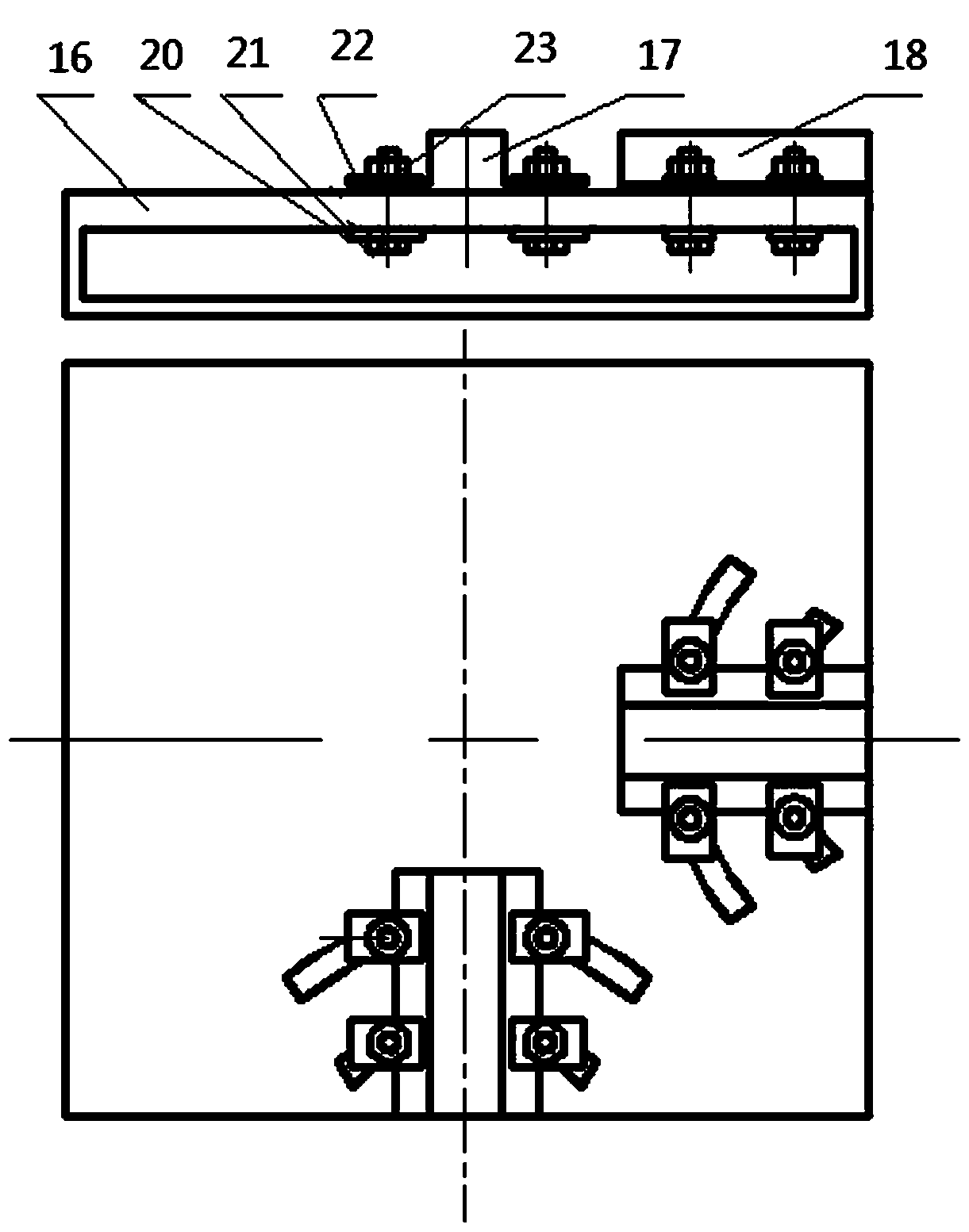

[0023] The artificial trachea 3D printing device of the present invention is made up of electronic part, printer and software, wherein electronic part includes system board, mainboard, motor driver board, temperature control board, heating tube, thermocouple, hot bed; The material drum and the guide rail are characterized in that X, Y, and Z three-dimensional guide rails are arranged on the printer body 15, and the X, Y, and Z direction guide rails are respectively arranged in three rows along their respective directions, and the X guide rails are respectively 4, 6, and 9; Y guide rails are 3, 5, 8 respectively; Z guide rails are 11, 12, 19 respectively. Each Y guide rail is connected to the machine body along the Y direction, each X guide rail is connected to the Y guide rail through a slider; each Z guide rail is connected to the X guide rail through a slider.

[0024] Y guide rail 5, Y guide rail 8, Y guide rail 3 move along the Y direction, X guide rail 6, X guide rail 9, ...

Embodiment 2

[0029] The artificial trachea process of the present invention is as follows:

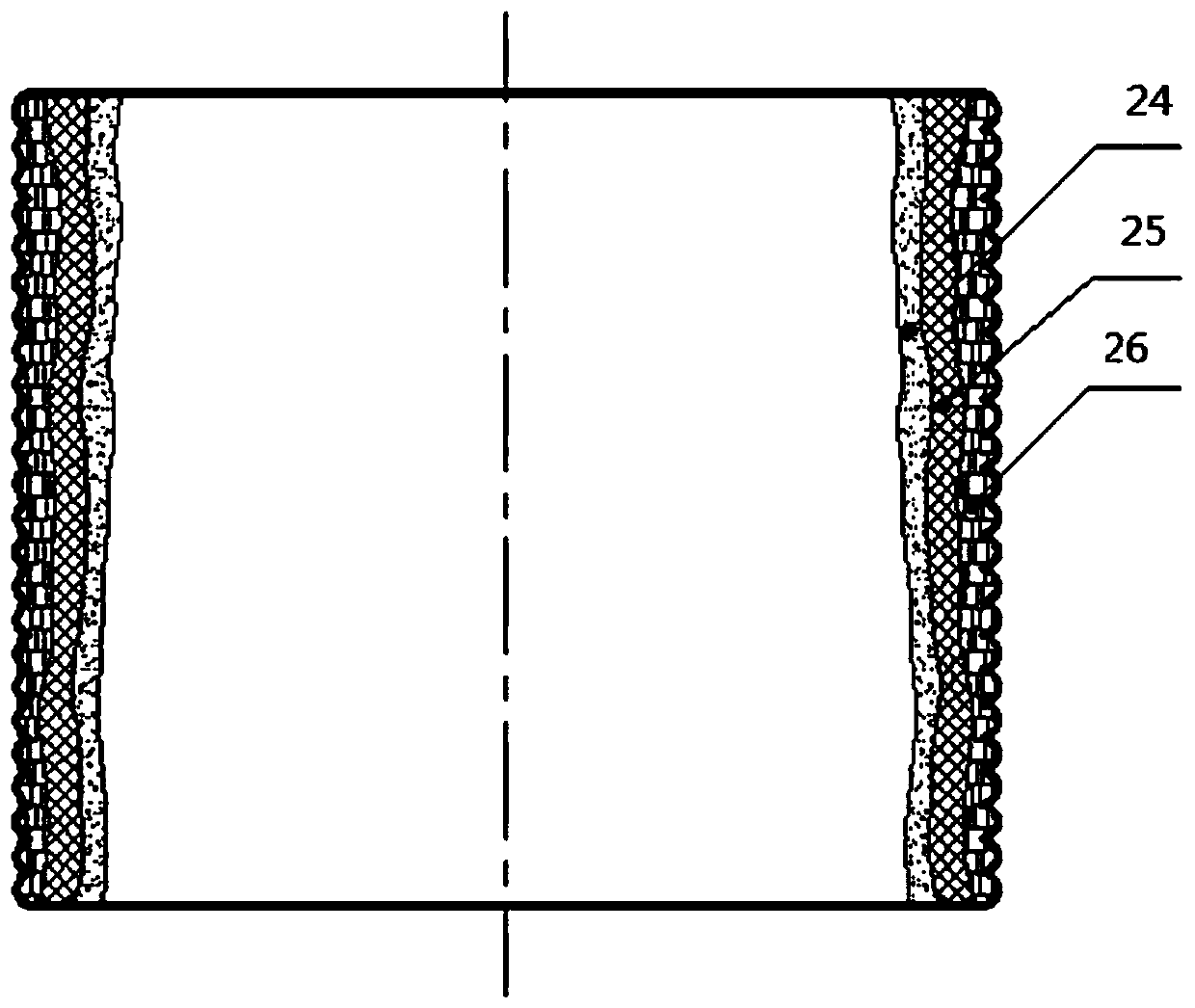

[0030] Step 1: Establish the 3D digital printing model of the artificial trachea: According to the mechanical performance calculation and experimental test, and compare the mechanical properties of the human trachea, design the three-layer artificial trachea according to the material composition, three-layer structure, specific shape and size of the artificial trachea The thickness ratio between.

[0031] Step 2, preparing three 3D printing materials for 3D printing: collagen, carbon fiber, and silica gel.

[0032] Step 3, adjust and fix the installation positions of the two ultrasonic vibration devices on the ultrasonic movable workbench, adjust the vibration amplitude to 0.1mm, and adjust the vibration frequency to 20kHz.

[0033] Step 4: Import the 3D digital model of the artificial trachea into the printer, set up the printing process, print the outer layer of the artificial trachea with a 0.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com