Preparation method of multiscale toughened brick-mud structural super high-temperature ceramic material

A multi-scale technology for ultra-high temperature ceramics, applied in the field of preparation of functional ceramic materials, can solve problems such as anisotropy and poor damage tolerance, and achieve the effect of improving damage tolerance and reducing anisotropy problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

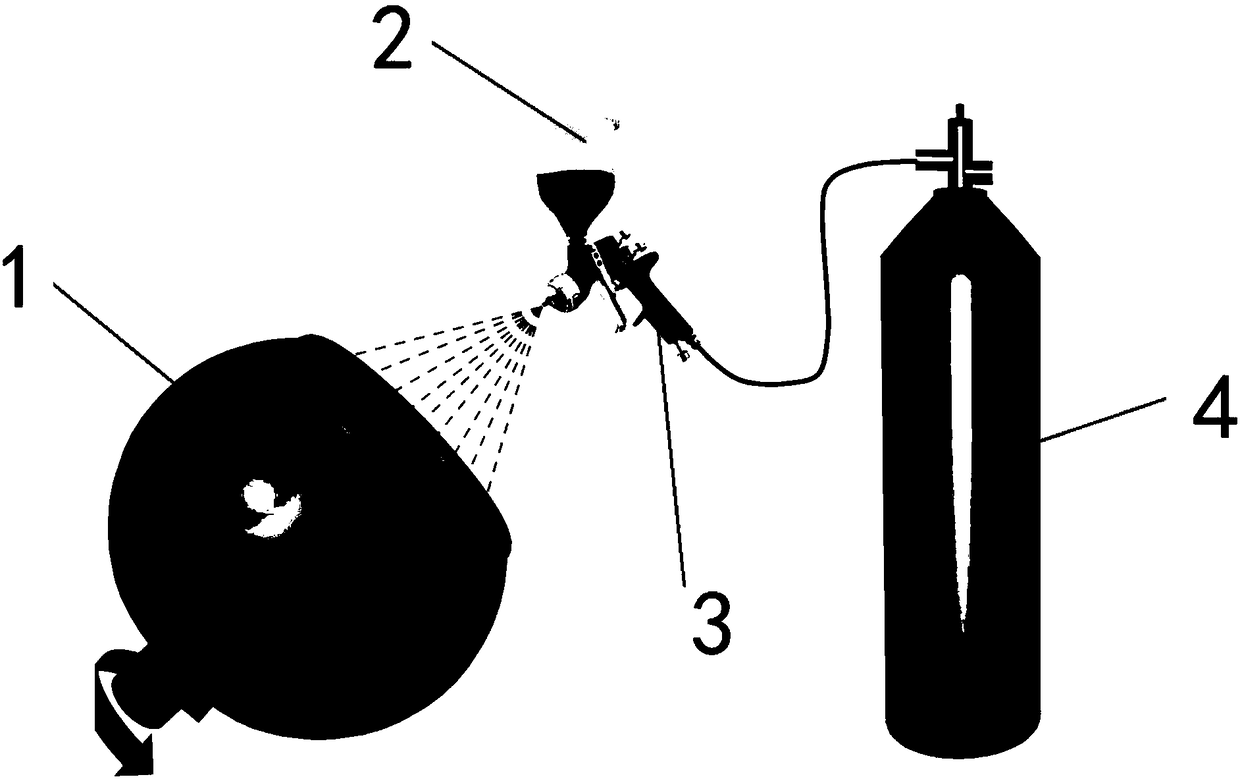

[0026] Embodiment 1: In this embodiment, a method for preparing a multi-scale toughened brick-mud structure ultra-high temperature ceramic material is specifically carried out according to the following steps:

[0027] 1. ZrB 2 After the powder and SiC powder are mixed, they are ball-milled for 8-12 hours at a ball-milling speed of 180-240r / min, and then vacuum-rotated to obtain ZrB 2 -SiC composite powder; the ZrB 2 The volume ratio of powder to SiC powder is 1:(0.2~0.5);

[0028] Second, the ZrB 2 - Put the SiC composite powder into the centrifugal granulation coating pot, and spray the polyvinyl alcohol aqueous solution with a mass fraction of 2% in the spray gun into the coating pot under the condition of rotating speed of 10-30r / min and high-pressure gas assistance and control the rotation of the coating pan to coat the polyvinyl alcohol aqueous solution with a mass fraction of 2% on the ZrB 2 -SiC composite powder surface, coating time is

[0029] 15~30min, get ZrB ...

specific Embodiment approach 2

[0036] Specific embodiment two: the difference between this embodiment and specific embodiment one is: ZrB described in step one 2 The purity of the powder is 98%, and the average particle diameter is 1-2 μm. The purity of the SiC powder is 99%, and the average particle diameter is 0.5 μm. Others are the same as in the first embodiment.

[0037] ZrB described in this embodiment mode 2 The powder was purchased from Beijing Huaruike Chemical Co., Ltd.; the SiC powder was purchased from China Aladdin Reagent Co., Ltd.

specific Embodiment approach 3

[0038] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step one, ZrB 2 The volume ratio of powder to SiC powder is 1:0.25. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com