Method for accelerating ageing of vinegar by cooperation of ultrasonic waves and pulsed magnet field

A pulsed magnetic field and ultrasonic technology, which is applied in the field of ultrasonic and pulsed magnetic field to accelerate vinegar aging, can solve the problems of long aging time, large floor space, increased production cost, etc., and achieve short processing time, good effect and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

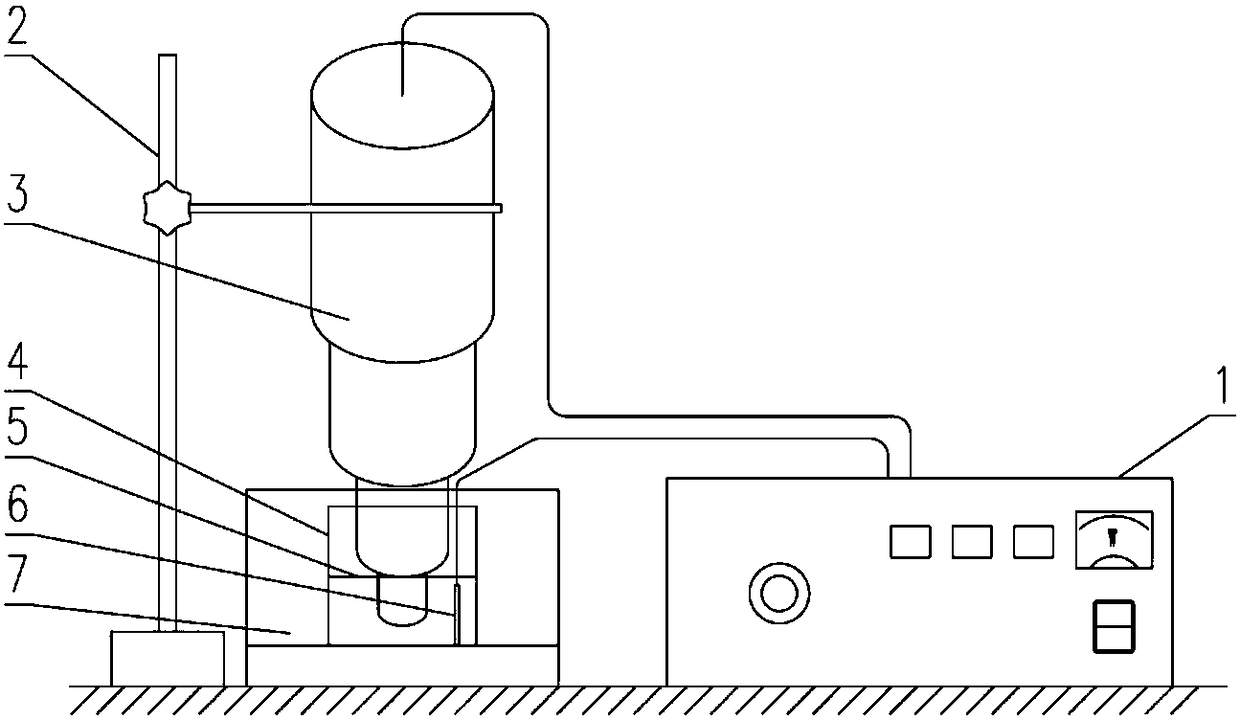

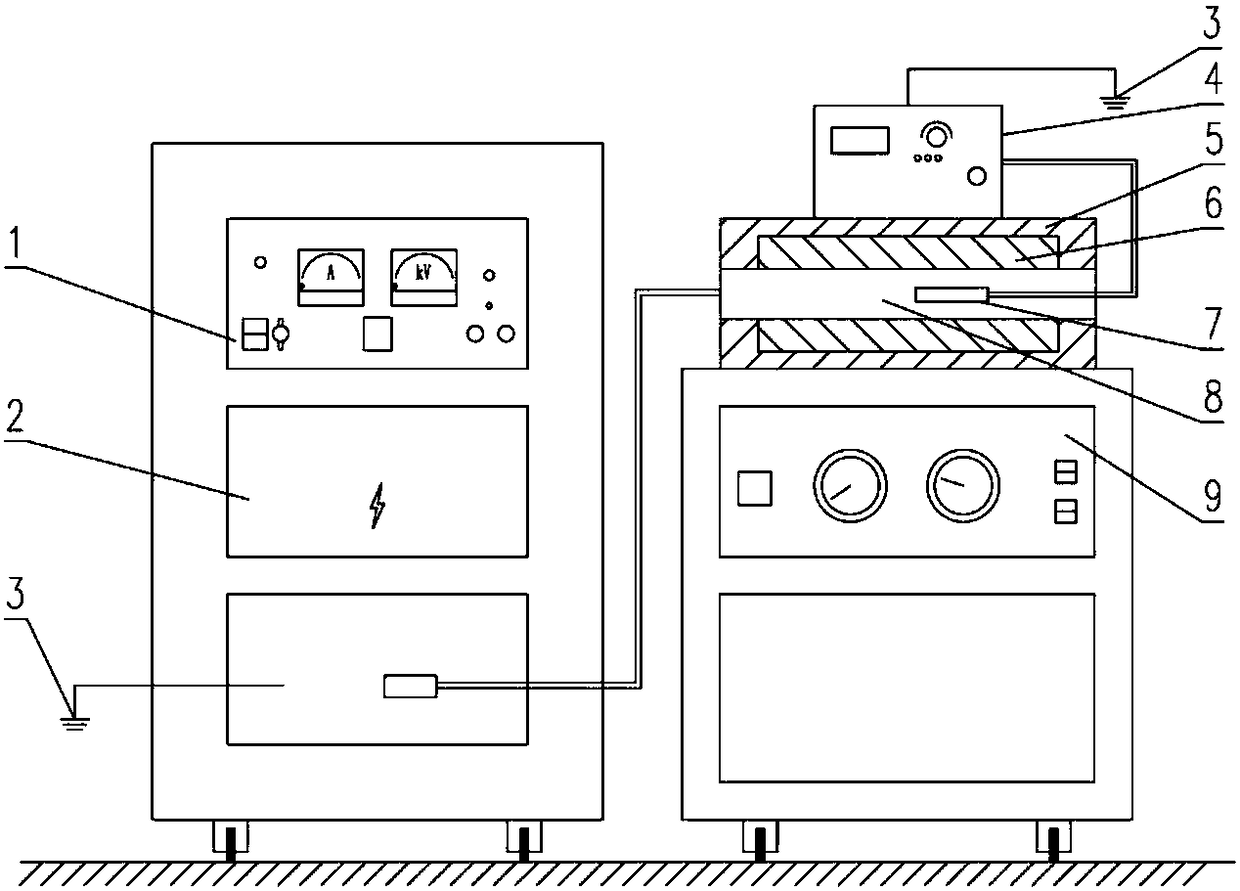

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1. Accurately measure 100mL of new brewed vinegar and add it to a 250mL container, add 0.55% ethanol, extend the horn and the probe into the container and seal the film. Maintain the temperature of the vinegar solution at 30°C, apply ultrasonic frequency of 20kHz, ultrasonic power density of 40W / 100mL, and ultrasonic treatment time of 30min. After the vinegar is treated by ultrasonic, pulse magnetic field treatment is applied, the magnetic field intensity is 2T, and the number of pulses is 10 times. The total acid, total ester, reducing sugar, and amino nitrogen content were determined to be 5.547, 2.685, 3.145, and 0.191g / 100mL, respectively, which were 5.718, 5.611, and 5.540g / 100g / 100mL compared with fresh vinegar and traditional naturally aged 4-5 years old vinegar. , total ester 1.662, 2.670, 2.764g / 100mL, reducing sugar 3.431, 2.824, 2.728g / 100mL, aminopeptide nitrogen 0.252, 0.189, 0.184g / 100mL, the trend of content change is consistent.

Embodiment 2

[0026] Embodiment 2. Accurately measure 100mL of new brewed vinegar and add it to a 250mL container, add 0.60% ethanol, extend the horn and the probe into the container and seal the film. Maintain the temperature of the vinegar solution at 35°C, apply ultrasonic frequency of 24kHz, ultrasonic power density of 50W / 100mL, and ultrasonic treatment time of 40min. After the vinegar is treated with ultrasonic waves, a pulsed magnetic field is applied with a magnetic field intensity of 3T and a pulse frequency of 15 times. The total acid, total ester, reducing sugar, and amino nitrogen content were determined to be 5.486, 2.692, 2.845, and 0.167g / 100mL, respectively, which were 5.718, 5.611, and 5.540g / 100g / 100mL compared with fresh vinegar and traditional naturally aged 4-5 year old vinegar. , total ester 1.662, 2.670, 2.764g / 100mL, reducing sugar 3.431, 2.824, 2.728g / 100mL, aminopeptide nitrogen 0.252, 0.189, 0.184g / 100mL, the trend of content change is consistent.

Embodiment 3

[0027]Embodiment 3. Accurately measure 100mL of new brewed vinegar and add it to a 250mL container, add 0.65% ethanol, extend the horn and the probe into the container and seal the film. Maintain the temperature of the vinegar liquid at 40°C, apply ultrasonic frequency of 28kHz, ultrasonic power density of 60W / 100mL, and ultrasonic treatment time of 50min. After the vinegar is ultrasonically treated, pulse magnetic field treatment is applied, the magnetic field intensity is 4T, and the number of pulses is 20 times. The total acid, total ester, reducing sugar, and amino nitrogen content were determined to be 5.463, 2.724, 2.735, and 0.178g / 100mL, respectively, which were 5.718, 5.611, and 5.540g / 100g / 100mL compared with fresh vinegar and traditional naturally aged 4-5 year old vinegar. , total ester 1.662, 2.670, 2.764g / 100mL, reducing sugar 3.431, 2.824, 2.728g / 100mL, aminopeptide nitrogen 0.252, 0.189, 0.184g / 100mL, the trend of content change is consistent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com