Fine metal mask plate, preparation method thereof and mask integrated framework

A fine metal mask and mask plate technology, which is applied in metal material coating process, printed circuit manufacturing, photoplate making process of pattern surface, etc., can solve the problem of pattern edge deviation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

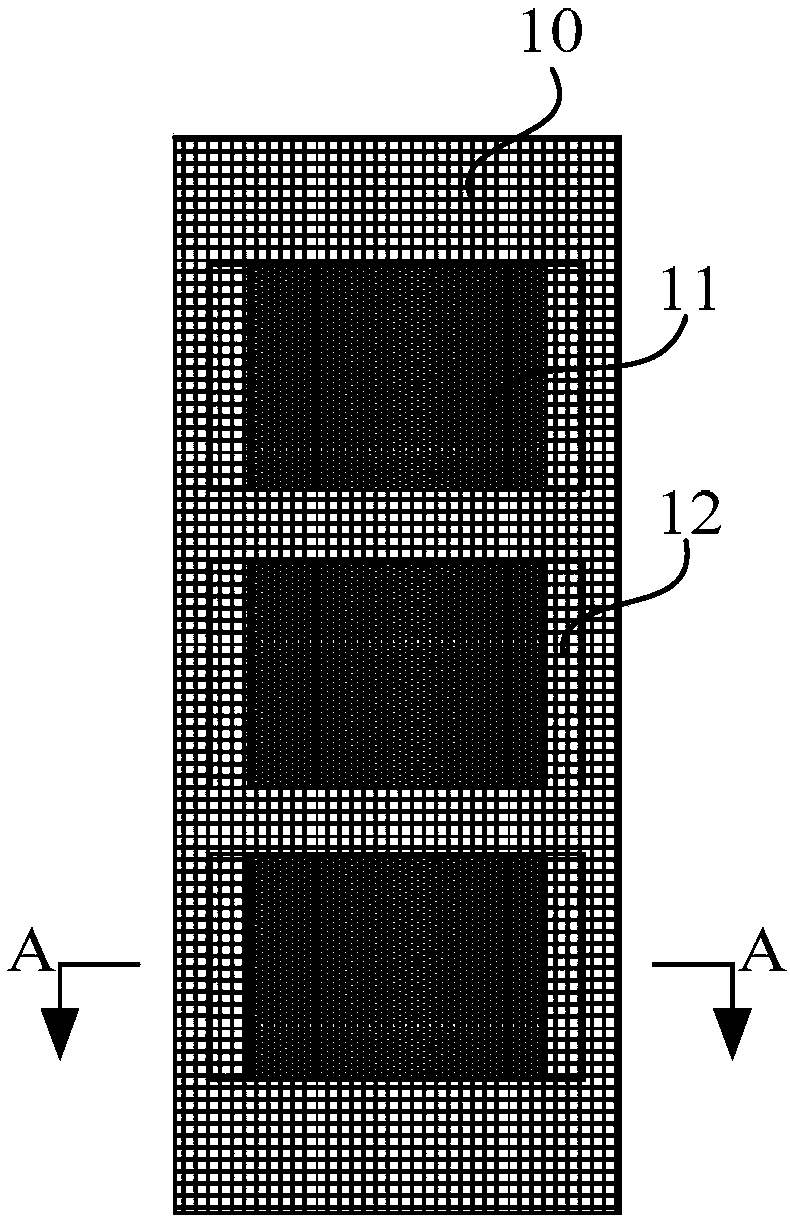

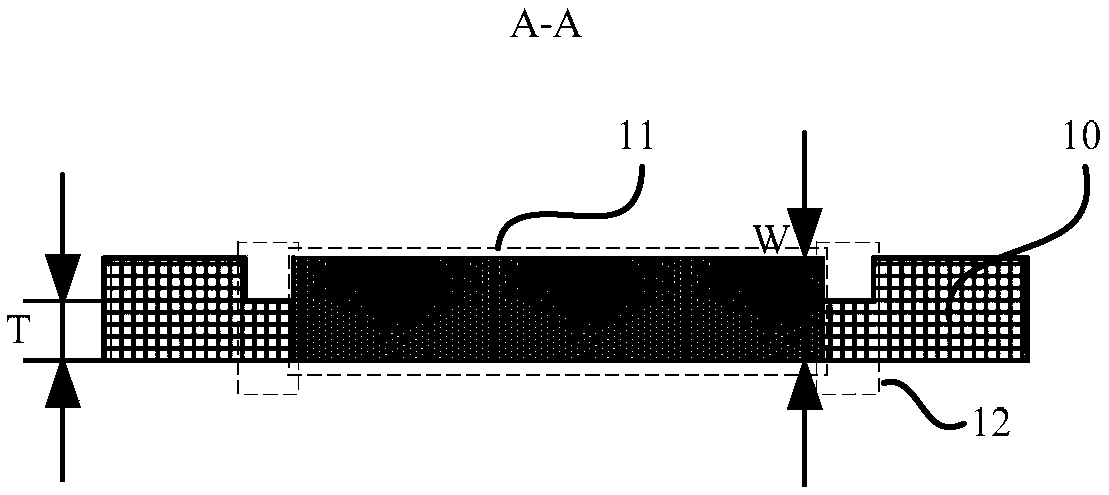

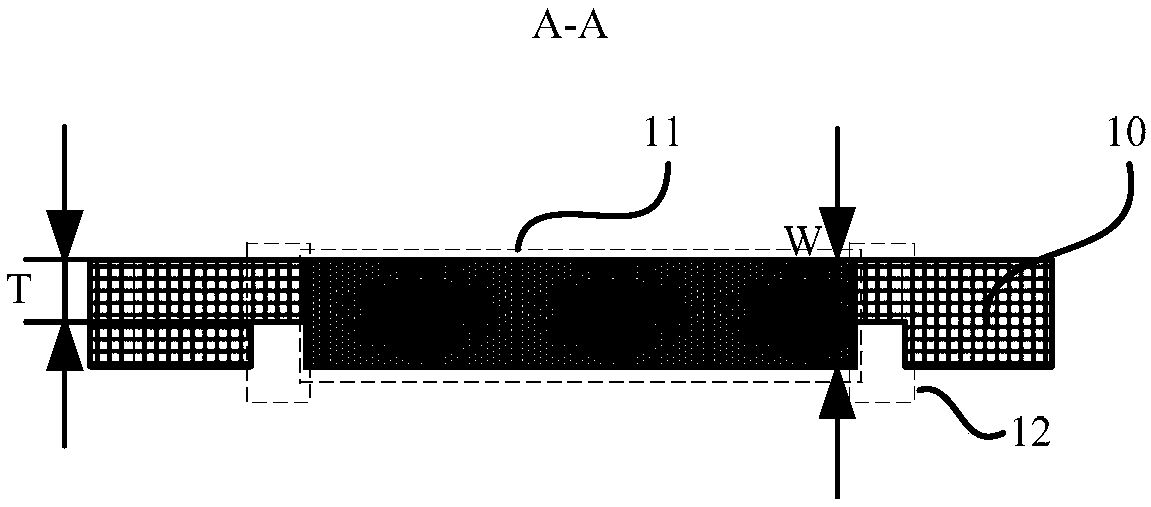

[0064] Another aspect of the embodiments of the present invention provides a method for preparing a fine metal mask, such as Figure 7 shown, including:

[0065] S101 , making a mask pattern on the metal sheet to form a mask pattern region 11 .

[0066] S102 , thinning at least one side surface of the metal sheet along at least one side edge of the mask pattern area 11 and in contact with the edge is located on at least one side surface of the fine metal mask 10 to form a protection area 12 .

[0067] Making the fine metal mask 10 of the embodiment of the present invention includes making two parts of the mask pattern region 11 and the protection region 12 on the metal sheet. It should be noted that, in the embodiment of the present invention, for making the mask pattern region 11 ( The order of step S101) and making the protected area 12 (step S102) is not specifically limited, and the mask pattern area 11 can be made on the metal sheet first, that is, step S101 is performed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com