Process for preparing water-permeable material for landscaping pavement

A water seepage material and landscaping technology, which is applied in the field of preparing water seepage materials for landscaping pavement, can solve the problems of insufficient compressive strength, low ability to adjust the temperature and humidity of the urban surface, and silted rivers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

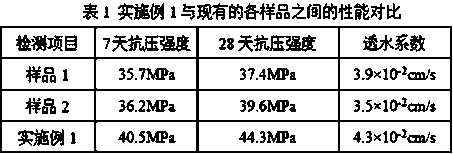

Embodiment 1

[0031]A process for preparing water-permeable material for landscaping pavement, said water-permeable material comprises a water-permeable layer on the upper layer and a base layer on the lower layer, and the preparation process comprises the following steps:

[0032] (1) In parts by weight, take 45 parts of binder, 120 parts of solid waste coarse aggregate, 100 parts of solid waste fine aggregate, 10 parts of admixture, and 15 parts of water, and add water and admixture to the cement , stir for 1~2min, put in the solid waste coarse aggregate and continue to stir for 1~2min, then add the solid waste fine aggregate, after stirring evenly, inject it into the mold and press it into shape, place it on a vibrating table to vibrate compactly, and demould Obtain the basal layer for use;

[0033] (2) In parts by weight, take 40 parts of binder, 80 parts of solid waste coarse aggregate, 10 parts of water-absorbing resin, 80 parts of fiber, 5 parts of admixture, and 8 parts of water, an...

Embodiment 2

[0053] A process for preparing water-permeable material for landscaping pavement, said water-permeable material comprises a water-permeable layer on the upper layer and a base layer on the lower layer, and the preparation process comprises the following steps:

[0054] (1) In parts by weight, take 50 parts of binder, 150 parts of solid waste coarse aggregate, 110 parts of solid waste fine aggregate, 15 parts of admixture, and 20 parts of water, and add water and admixture to the cement , stir for 1~2min, put in the solid waste coarse aggregate and continue to stir for 1~2min, then add the solid waste fine aggregate, after stirring evenly, inject it into the mold and press it into shape, place it on a vibrating table to vibrate compactly, and demould Obtain the basal layer for use;

[0055] (2) In parts by weight, take 42 parts of binder, 90 parts of solid waste coarse aggregate, 15 parts of water-absorbing resin, 100 parts of fiber, 7 parts of admixture, and 9 parts of water, ...

Embodiment 3

[0076] A process for preparing water-permeable material for landscaping pavement, said water-permeable material comprises a water-permeable layer on the upper layer and a base layer on the lower layer, and the preparation process comprises the following steps:

[0077] (1) In parts by weight, take 55 parts of binder, 180 parts of solid waste coarse aggregate, 120 parts of solid waste fine aggregate, 20 parts of admixture, and 25 parts of water, and add water and admixture to the cement , stir for 1~2min, put in the solid waste coarse aggregate and continue to stir for 1~2min, then add the solid waste fine aggregate, after stirring evenly, inject it into the mold and press it into shape, place it on a vibrating table to vibrate compactly, and demould Obtain the basal layer for use;

[0078] (2) In parts by weight, take 45 parts of binder, 100 parts of solid waste coarse aggregate, 20 parts of water-absorbing resin, 120 parts of fiber, 8 parts of admixture, and 10 parts of water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com