Chemically amplified positive resist composition and resist pattern forming process

一种正型抗蚀剂、组合物的技术,应用在有机化学、光学、图纹面的照相制版工艺等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0192] Examples of the invention are given below by way of illustration and not by way of limitation. The abbreviation "pbw" means parts by weight. THF is tetrahydrofuran. The copolymer composition is represented by molar ratio. Mw was determined by GPC against polystyrene standards. Analytical instruments are shown below.

[0193] IR: NICOLET 6700 manufactured by Thermo Fisher Scientific Inc.

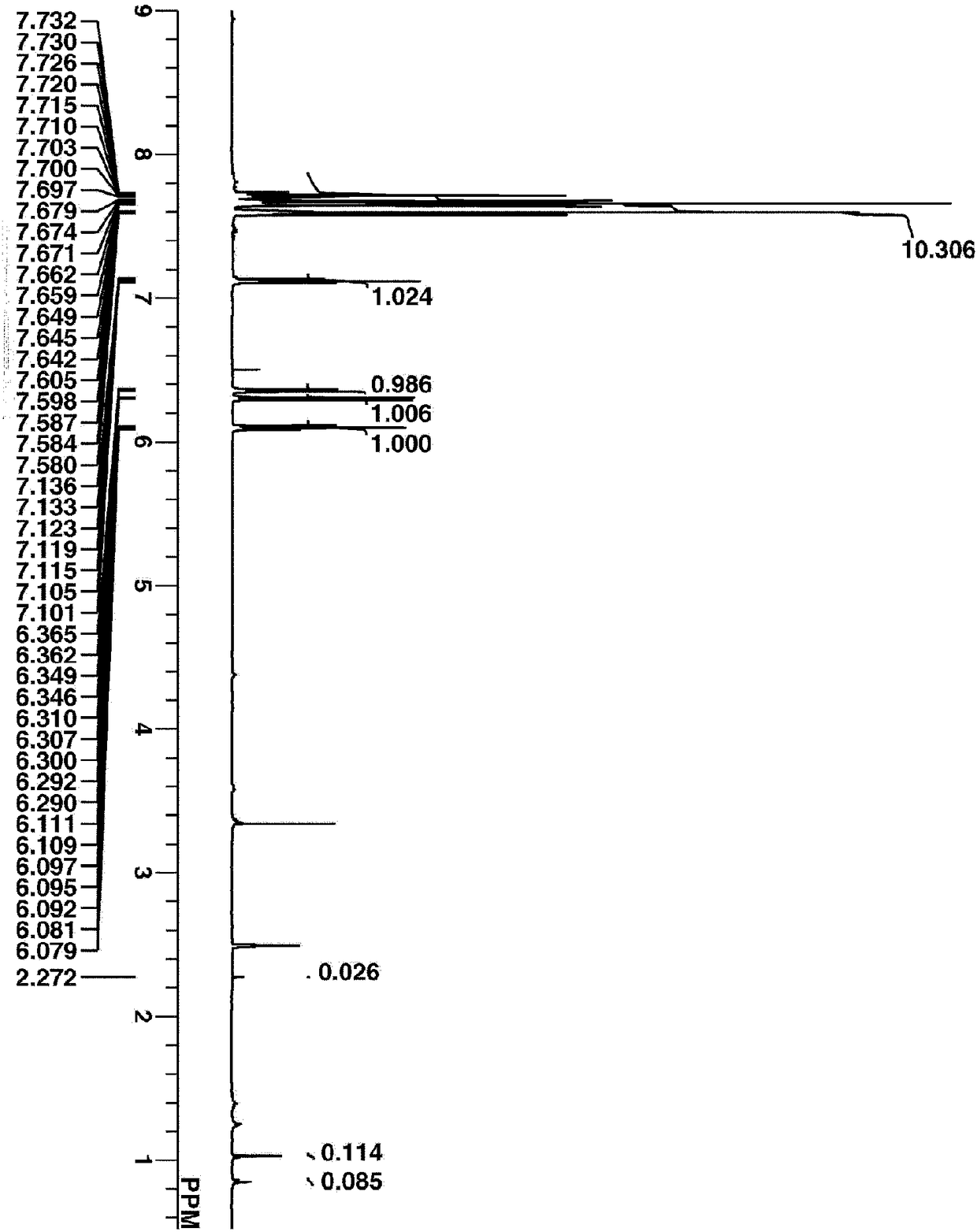

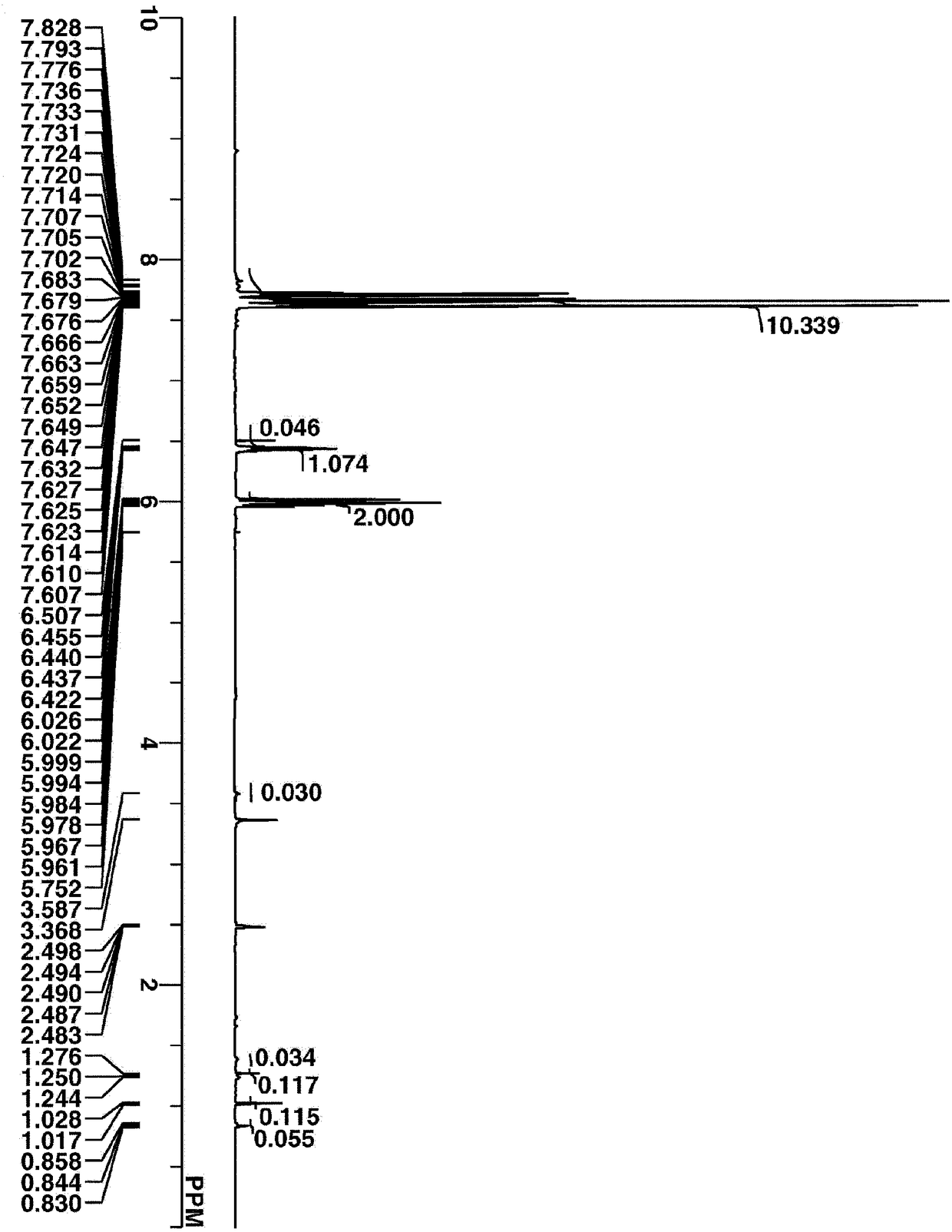

[0194] 1 H-NMR: ECA-500 manufactured by JEOL Ltd.

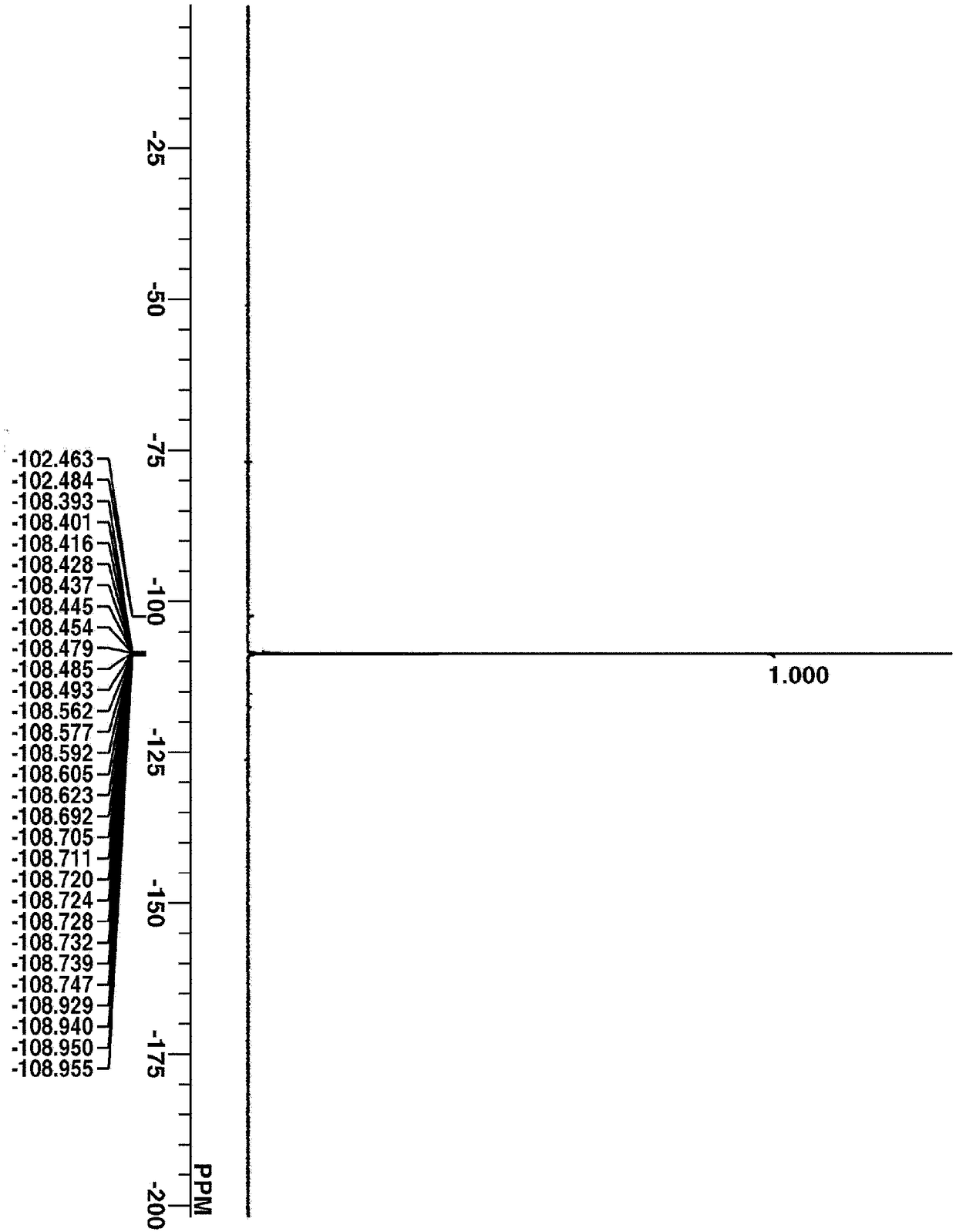

[0195] 19 F-NMR: ECA-500 manufactured by JEOL Ltd.

[0196] LC-MS: ACQUITY UPLC H-Class System and ACQUITY QDa manufactured by Waters.

[0197] 1) Synthesis of sulfonium compounds

Synthetic example 1

[0199] Synthesis of 2-(diphenylsulfonium)phenoxide Q-1

Synthetic example 1-1

[0201] Synthesis of (2-tert-butoxyphenyl)diphenylsulfonium chloride (intermediate A)

[0202]

[0203] The Grignard reagent was prepared using standard methods in THF using 2.6 g of magnesium and 16 g of 2-tert-butoxychlorobenzene. 6.1 g of diphenylsulfoxide and 27 g of THF were added to the Grignard reagent. Then, 9.8 g of chlorotrimethylsilane was added dropwise to this solution at room temperature, and aged for 3 hours. After aging, a saturated aqueous ammonium chloride solution was added to quench the reaction, and 100 g of water was added to the reaction solution, washed with diisopropyl ether to obtain the target compound (2-tert-butoxyphenyl) di Aqueous solution of phenylsulfonium chloride (designated as Intermediate A). This compound was fed to the next step without isolation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com