Negative pole piece as well as preparation method thereof, and lithium ion battery

A technology of negative electrode sheet and negative electrode is applied in the field of negative electrode sheet and its preparation, which can solve problems such as hidden dangers of battery safety, and achieve the effects of reducing the occurrence probability, lowering the edge coating amount, and reducing safety accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Simultaneously, the present invention also provides the preparation method of above-mentioned negative plate, comprises the following steps:

[0048] providing a slurry of the first negative electrode material;

[0049] providing a slurry of the second negative electrode material;

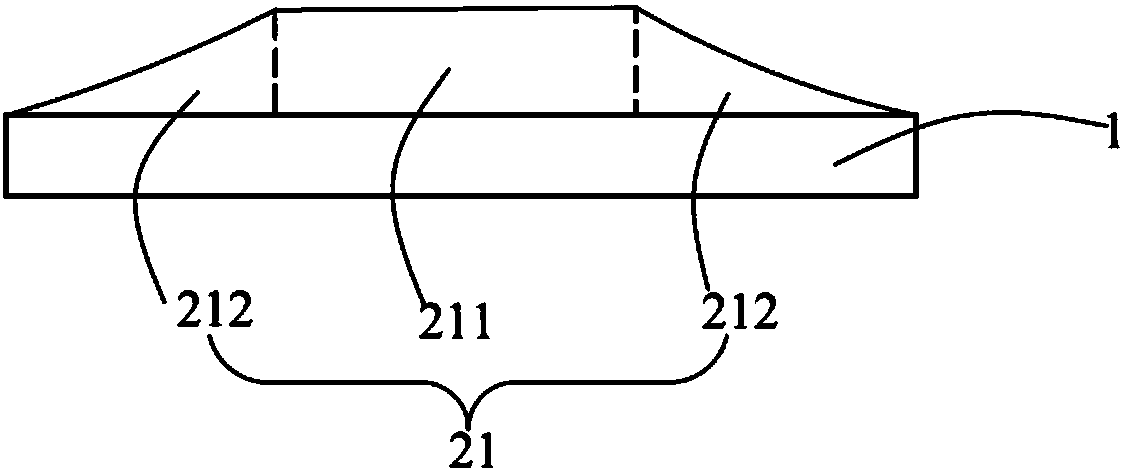

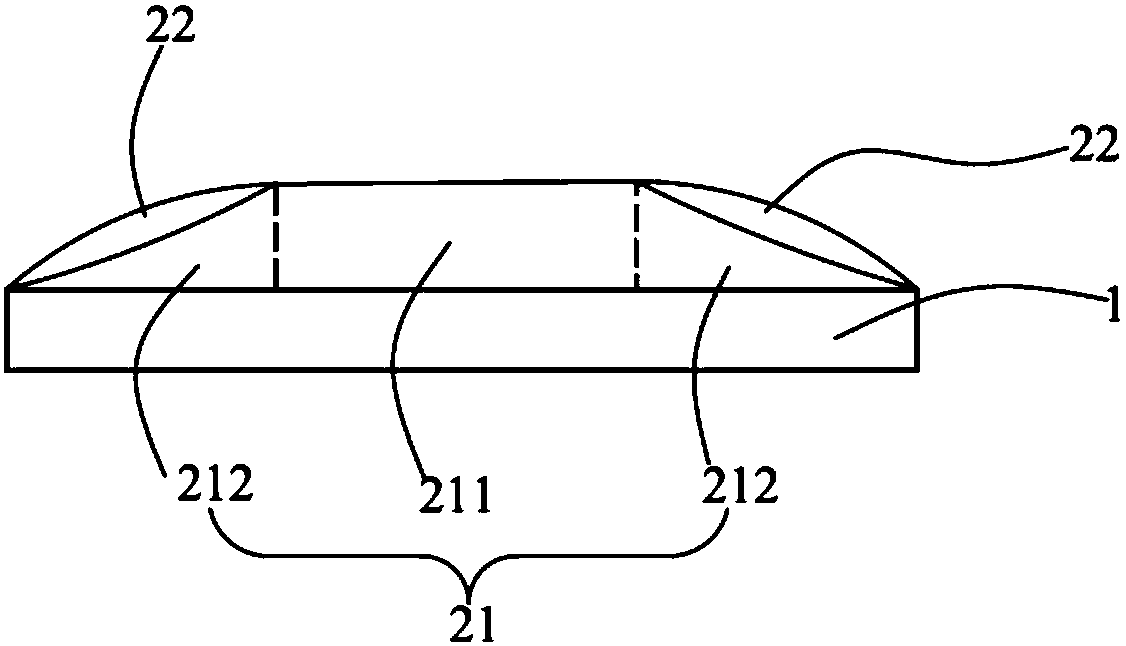

[0050] Coating the slurry of the first negative electrode material on the surface of the negative electrode current collector 1 to form a first negative electrode material layer 21, the first negative electrode material layer 21 includes a first material region 211 and a second material region at the edge of the first material region 211 212, the thickness of the first material region 211 is greater than the thickness of the second material region 212, the slurry material of the second negative electrode material is coated on the surface of the second material region 212 to form a second negative electrode material layer 22, and then dried to form a negative electrode Material layer 2, to o...

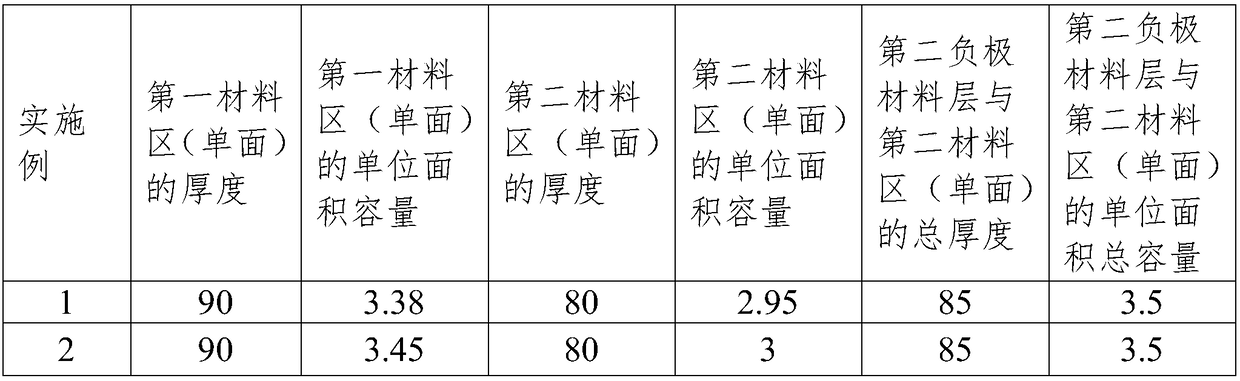

Embodiment 1

[0067] 1. Preparation of negative electrode sheet

[0068] 1.1 Slurry preparation of the first negative electrode material.

[0069] First prepare CMC (sodium carboxymethylcellulose) into an aqueous solution;

[0070] Add conductive carbon black in the CMC aqueous solution and mix and stir, then add artificial graphite (produced by Shenzhen Beiterui New Energy Materials Co., Ltd., the gram capacity is 360mAH / g) and continue to stir;

[0071] Then add SBR (styrene-butadiene rubber) emulsion and continue to mix and stir evenly. Wherein the weight ratio of artificial graphite: conductive carbon black: CMC: SBR is 96:1:1.5:1.5.

[0072] 1.2 Preparation of slurry for the second negative electrode material.

[0073] First prepare CMC into an aqueous solution;

[0074] Add conductive carbon black to the CMC aqueous solution for mixing and stirring, then add silicon oxide carbon composite material (purchased from Shenzhen Betterui New Energy Materials Co., Ltd., the gram capacity ...

Embodiment 2

[0086] Negative electrode sheets, positive electrode sheets, and lithium-ion batteries were prepared according to the method of Example 1, the difference being that the weight ratio of artificial graphite:CMC:SBR in the slurry of the first negative electrode material was 98:1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com