Color forming device, color forming system, color forming method and multi-color 3D (Three-dimensional) printer using device

A coloring and printing head technology, applied in the field of coloring system, can solve the problem of coloring of multi-color 3D printer raw materials, etc., and achieve the effect of improving printing efficiency, uniform coloring, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] This embodiment is an attempt in the laboratory stage. Based on the experimental conditions and the current situation of the laboratory, the existing monochrome 3D printer in the laboratory is used to improve. Through improvement and research, a multi-color 3D printer with multi-color printing function is formed. , The application and use of this technology is not limited to the improvement of the color forming device of the existing single-color and multi-color 3D printers, new research and development and production links.

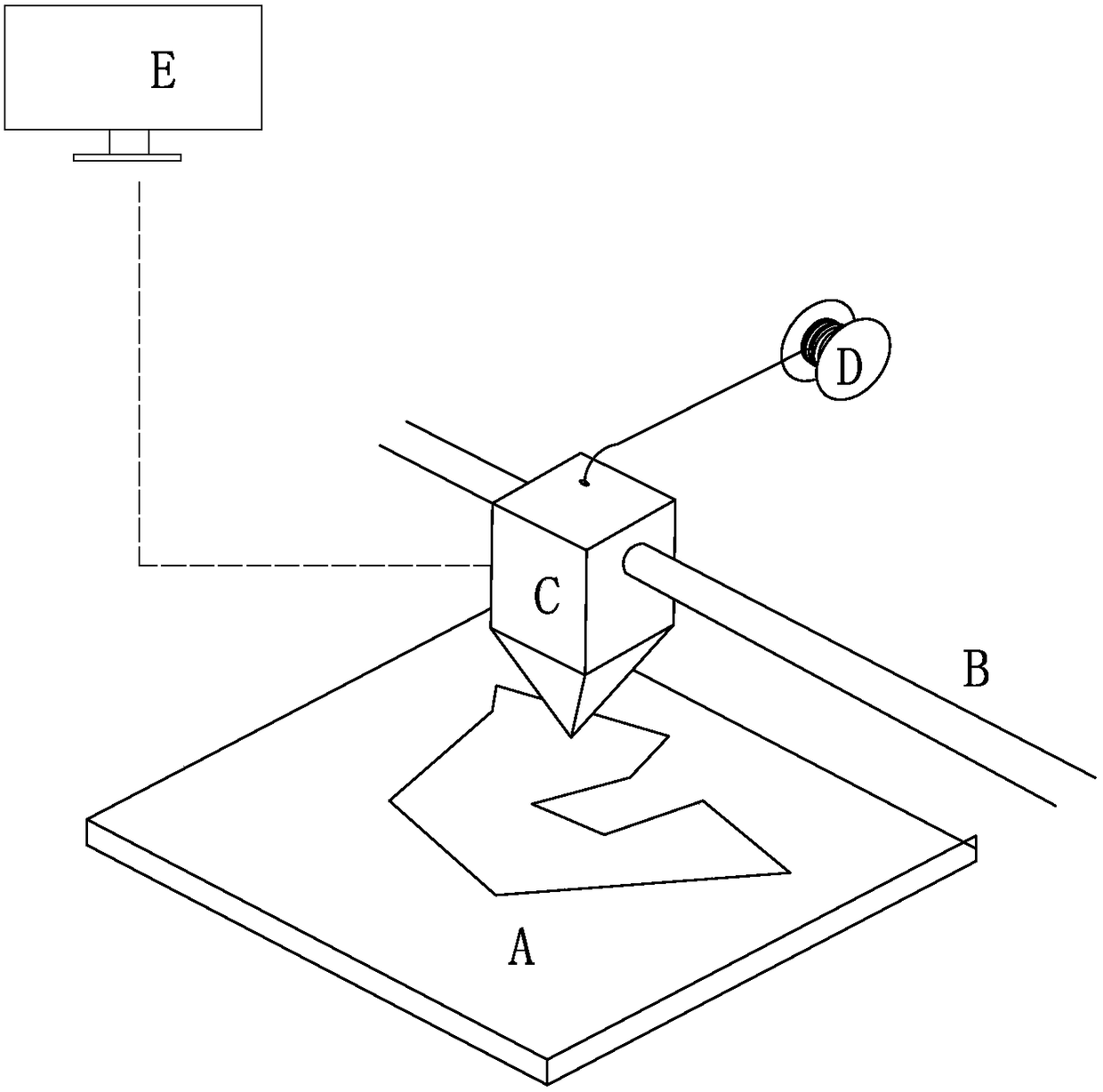

[0034] refer to figure 1 , a common 3D printer includes a workbench A, a head movement mechanism B, a printer head C, a wire feeding mechanism D and a control system E, wherein the head movement mechanism is driven by a drive motor and can move in the height direction and the horizontal direction to form Displacement capability in the three-dimensional space, the meltable plastic raw material line is melted in the printer head, extruded from the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com