High temperature-resistant and antibacterial silica gel cake mold

A cake mold and high temperature resistant technology, applied in the field of high temperature resistant antibacterial silicone cake molds, can solve the problems of shortened shelf life of cakes, mold easy to mold, no antibacterial properties, etc., to avoid bacterial growth, avoid low temperature embrittlement, and increase performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

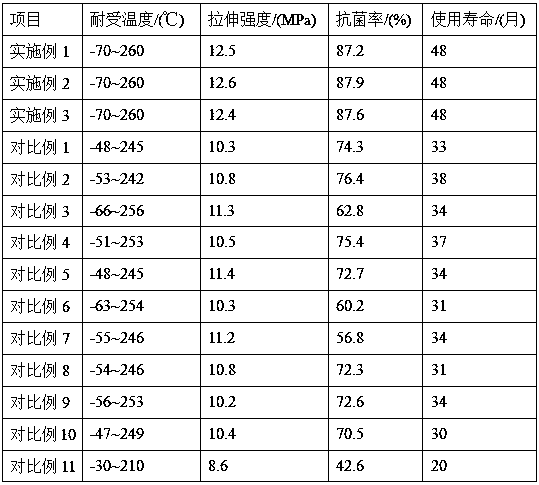

Examples

Embodiment 1

[0019] A high temperature resistant antibacterial silica gel cake mold made of the following parts by weight of raw materials: silicone rubber 63, natural rubber 37, hydroxypropyl cellulose 26, zeolite powder 14, fumed silica 11, chitosan 7, nanometer two Silicon oxide 4.

[0020] The zeolite powder has a particle size of 30-40 nm.

[0021] A method for preparing high temperature resistant antibacterial silica gel cake mold includes the following steps:

[0022] (1) Put the silicone rubber into the reaction kettle, slowly heat it to 210°C, the heating temperature is 1.5°C / min, keep it warm for 15 minutes, add chitosan, keep it warm and stir for 20 minutes to obtain a denatured silicone rubber;

[0023] (2) Put the natural rubber in the reactor, heat it to 170°C, add gas-phase white carbon black, continue heating to 220°C, stir evenly in a vacuum, and the vacuum degree is -0.3MPa to obtain denatured natural rubber;

[0024] (3) Mix the denatured silicone rubber, denatured natural rubber...

Embodiment 2

[0030] A high temperature resistant antibacterial silica gel cake mold, made of the following parts by weight of raw materials: silicone rubber 64, natural rubber 38, hydroxypropyl cellulose 27, zeolite powder 15, fumed silica 12, chitosan 8, nanometer two Silicon oxide 5.

[0031] The zeolite powder has a particle size of 30-40 nm.

[0032] A method for preparing high temperature resistant antibacterial silica gel cake mold includes the following steps:

[0033] (1) Put the silicone rubber into the reaction kettle, slowly heat to 215°C, the heating temperature is 1.6°C / min, keep warm for 18 minutes, add chitosan, keep warm and stir for 25 minutes to obtain denatured silicone rubber;

[0034] (2) Put the natural rubber in the reactor, heat it to 180°C, add gas-phase white carbon black, continue heating to 225°C, stir evenly in a vacuum, and the vacuum degree is -0.2MPa to obtain denatured natural rubber;

[0035] (3) Mix the denatured silicone rubber, denatured natural rubber and zeoli...

Embodiment 3

[0041] A high temperature resistant antibacterial silica gel cake mold, made of the following parts by weight of raw materials: silicone rubber 65, natural rubber 39, hydroxypropyl cellulose 28, zeolite powder 16, fumed silica 13, chitosan 9, nano two Silicon oxide 6.

[0042] The zeolite powder has a particle size of 30-40 nm.

[0043] A method for preparing high temperature resistant antibacterial silica gel cake mold includes the following steps:

[0044] (1) Put the silicone rubber into the reaction kettle, slowly heat to 220°C, the heating temperature is 1.7°C / min, keep it warm for 20 minutes, add chitosan, keep it warm and stir for 30 minutes to obtain a modified silicone rubber;

[0045] (2) Put the natural rubber in the reaction kettle, heat it to 190℃, add the gas-phase white carbon black, continue to heat to 230℃, stir evenly in a vacuum, and the vacuum degree is -0.1MPa to obtain denatured natural rubber;

[0046] (3) Mix the denatured silicone rubber, denatured natural rubb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com