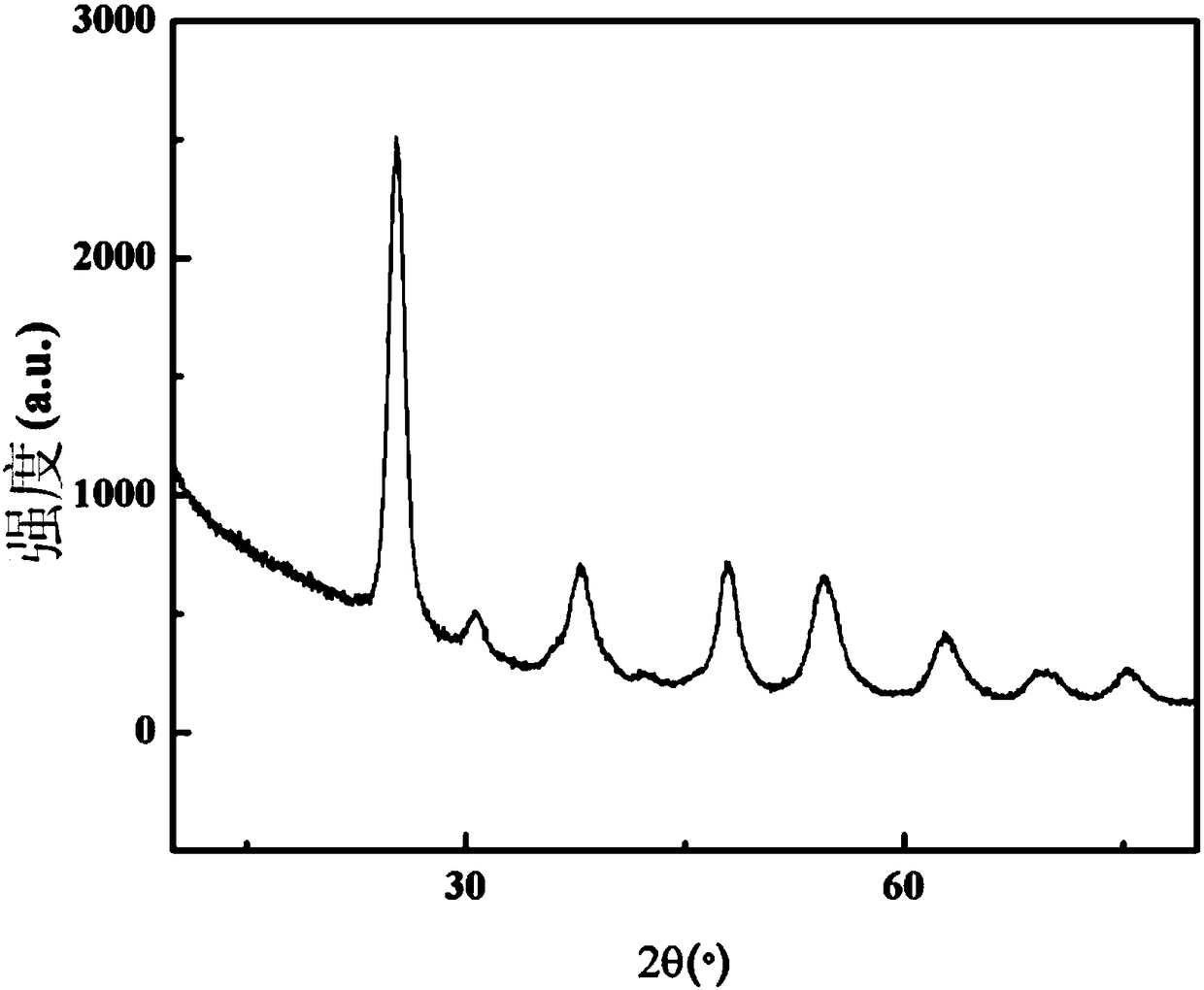

Preparation method and application of cerium-doped titanium dioxide/graphene aerogel

A graphene aerogel and titanium dioxide technology, applied in the field of aerogel, can solve the problems of poor catalytic activity of titanium dioxide and difficult recovery of powder materials, and achieve the effects of improving photocatalytic activity, being beneficial to reuse, and improving degradation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0039] Embodiment 1: This embodiment is a preparation method of cerium-doped titanium dioxide / graphene airgel, which is specifically completed according to the following steps:

[0040] 1. Preparation of graphene oxide solution:

[0041] Add ultrapure water to graphite oxide, and then ultrasonicate for 1h to 6h at an ultrasonic power of 30kHz to 60kHz to obtain a uniform brownish-brown graphene oxide solution; The graphene oxide solution was centrifuged for 3 minutes to 10 minutes, and the supernatant was taken to obtain a graphene oxide solution with a concentration of 1.5 mg / mL to 3.5 mg / mL;

[0042] The mass of graphite oxide described in step one and the volume ratio of ultrapure water are (0.24g~0.64g): 160mL;

[0043] 2. Preparation of cerium-doped titanium dioxide:

[0044] ①. Add tetrabutyl titanate to absolute ethanol at a stirring speed of 500r / min-1000r / min, and then stir for 3min-8min at a stirring speed of 500r / min-1000r / min to obtain solution A;

[0045]The vo...

specific Embodiment approach 2

[0065] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, ultrapure water is added to graphite oxide, and then ultrasonic power is 60kHz for 1h to 2h to obtain tan uniform graphene oxide solution; centrifuge the tan uniform graphene oxide solution at a centrifugation speed of 1000r / min-3000r / min for 3min-5min, take the upper layer of centrifugate, and obtain a graphene oxide solution with a concentration of 1.5mg / mL-2.5mg / mL . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0066] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass ratio of the graphite oxide described in step 1 to the ultrapure water is (0.24g-0.4g): 160mL. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com