Fuel oxidation desulfurization catalyst and preparation and application methods thereof

An oxidative desulfurization and catalyst technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, refining with oxygen-containing compounds, etc., can solve the problems of a large amount of waste water, a large amount of catalyst consumption, and difficulties in separation and recovery, and reduce the cost of industrial application , the catalyst consumption is reduced, and the preparation process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

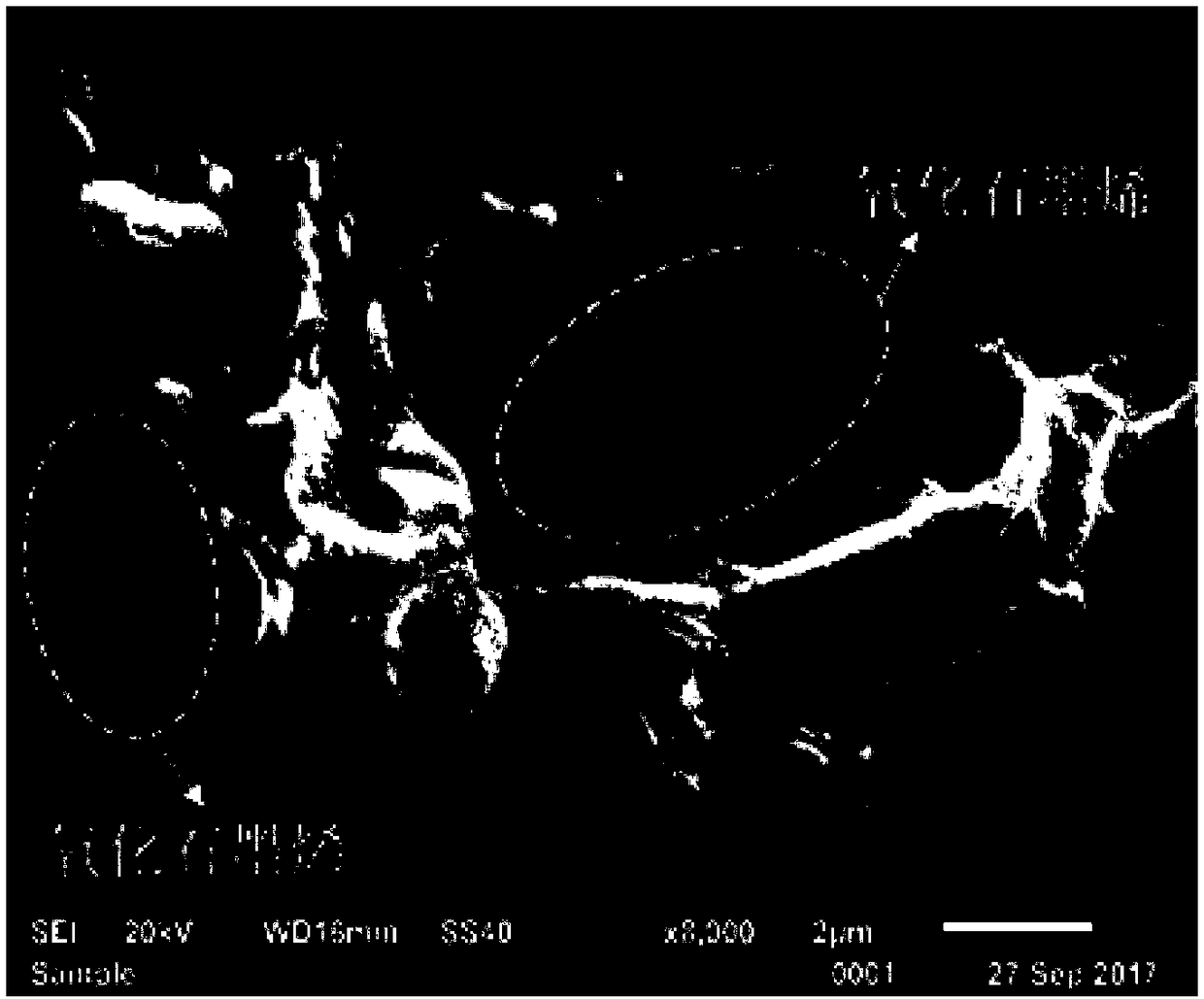

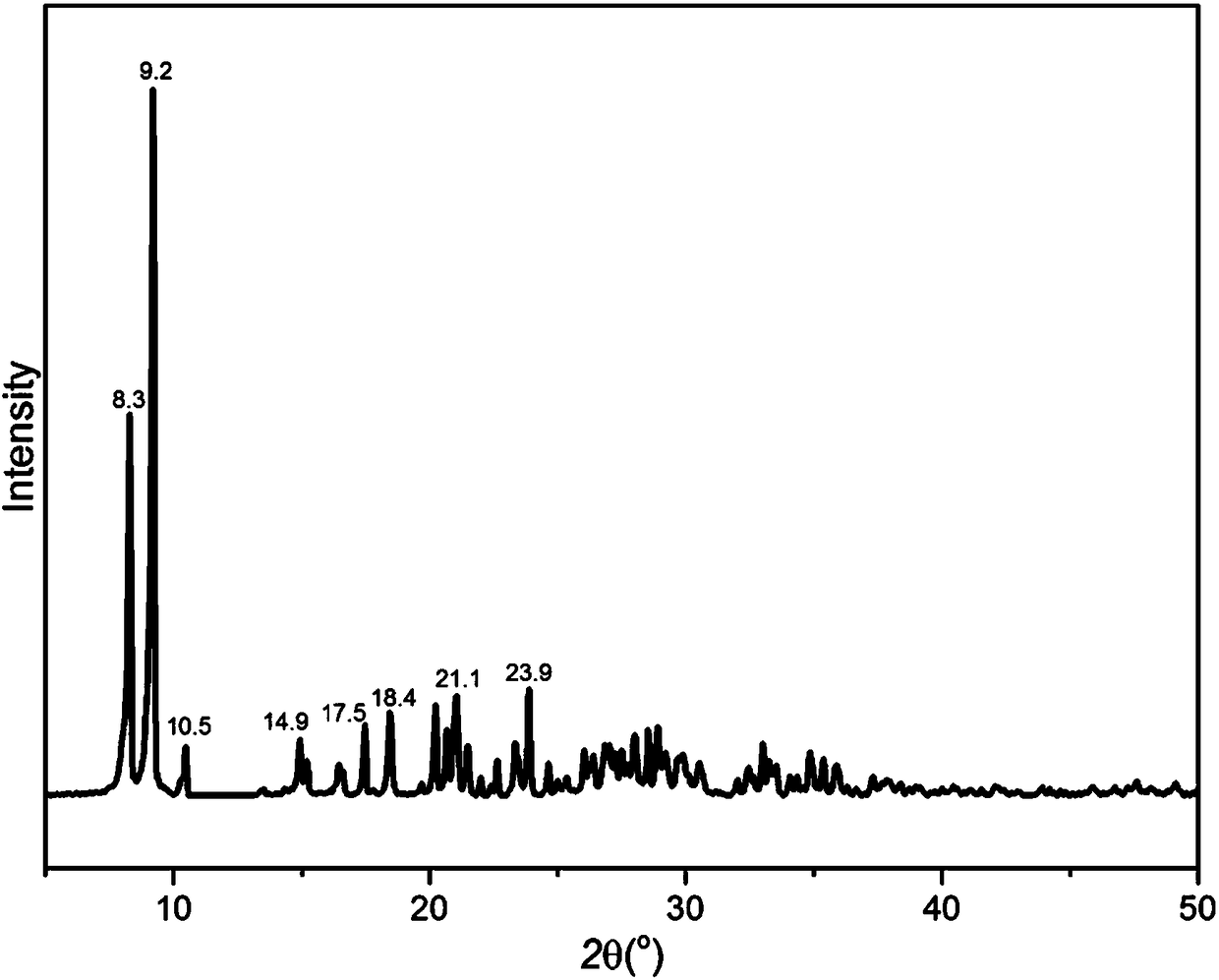

[0029] The preparation method of the fuel oil oxidative desulfurization catalyst is that graphene oxide solution and choline phosphotungstate solution are mixed and reacted to obtain graphene oxide-loaded choline phosphotungstate, that is, a fuel oil oxidative desulfurization catalyst.

[0030] Preferably, in the preparation method of the catalyst, the mass ratio of the graphene oxide solution to choline phosphotungstate is 1: (1.0~1.6); more preferably, in the preparation method of the catalyst, the graphene oxide solution and choline phosphotungstate The mass ratio of tungstate is 1:1.

[0031] Preferably, in the preparation method of the catalyst, the mass concentration of the graphene oxide solution is 0.8% to 1.2%; further preferably, in the preparation method of the catalyst, the mass concentration of the graphene oxide solution is 1%.

[0032] Preferably, in the preparation method of the catalyst, the mass concentration of the choline phosphotungstate solution is 8% to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com