Leaching agent for oily drilling cuttings and oily drilling waste and method of use thereof

A technology for drilling waste and drilling cuttings, which is applied in the field of leaching agent for deoiling treatment, can solve the problems of serious environmental pollution of oily operation waste, incomplete oil phase separation, and unsuitable treatment technology, so as to achieve reuse and avoid Secondary pollution and the effect of improving environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

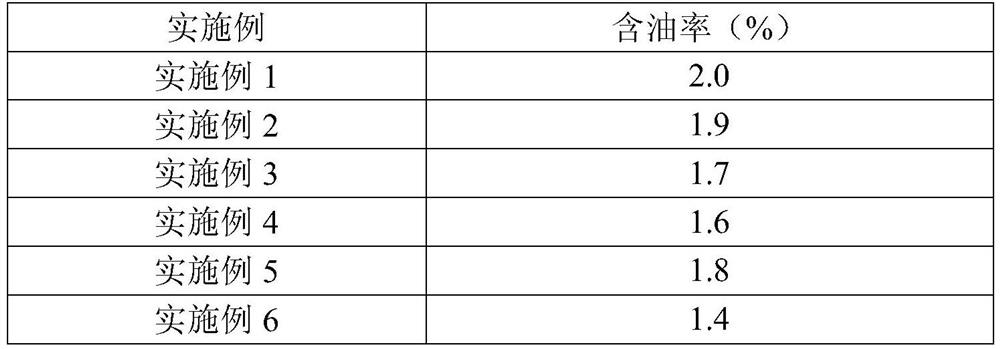

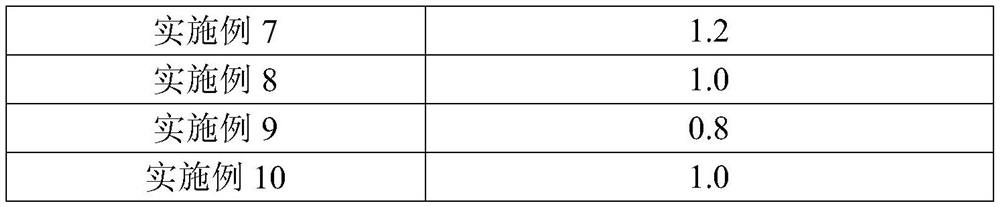

Examples

Embodiment 1

[0035] Weigh raw materials: 10 g of oily drilling cuttings, 60 ml of polyoxymethylene dimethyl ether with a degree of polymerization of 3.

[0036] Instructions:

[0037] Step 1: Place the weighed oily drill cuttings and leaching agent (60ml of polyoxymethylene dimethyl ether with a degree of polymerization of 3) in a stirrer and stir for 7min at a shear rate of 300r / min;

[0038] Step 2: After stirring, let it stand for a period of time, wait for the solid phase to settle, the solid and liquid will separate naturally, then remove the lower layer, centrifuge the solid phase, and dry at 95°C for 24 hours;

[0039] Step 3: After the leached oily drill cuttings and the leaching agent are subjected to solid-liquid separation, the liquid phase is placed in a three-necked flask, and then distilled at a temperature of 120°C and a negative pressure difference of 0.01MPa to obtain emulsification Diesel and leaching agent.

[0040] The leaching agent in this example does not require s...

Embodiment 2

[0042] Raw materials were weighed: 10 g of oily drill cuttings, 58 ml of polyoxymethylene dimethyl ether with a degree of polymerization of 3, and 2 ml of petroleum ether (boiling range: 60-90° C.).

[0043] Method of use: basically the same as in Example 1, except that the leaching agent is 58 ml of polyoxymethylene dimethyl ether with a degree of polymerization of 3 and 2 ml of petroleum ether (boiling range is 60-90° C.).

Embodiment 3

[0045] Raw materials were weighed: 10 g of oily drill cuttings, 56 ml of polyoxymethylene dimethyl ether with a degree of polymerization of 3, and 4 ml of petroleum ether (boiling range: 60-90° C.).

[0046] Method of use: basically the same as in Example 1, except that the leaching agent is 56 ml of polyoxymethylene dimethyl ether with a degree of polymerization of 3 and 4 ml of petroleum ether (boiling range is 60-90° C.).

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com