Multifunctional material distribution equipment and application method thereof

A multi-functional, cloth technology, applied in supply devices, manufacturing tools, etc., can solve the problems of large space occupied, low effective utilization of resources, and poor commonality of cloth equipment, and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

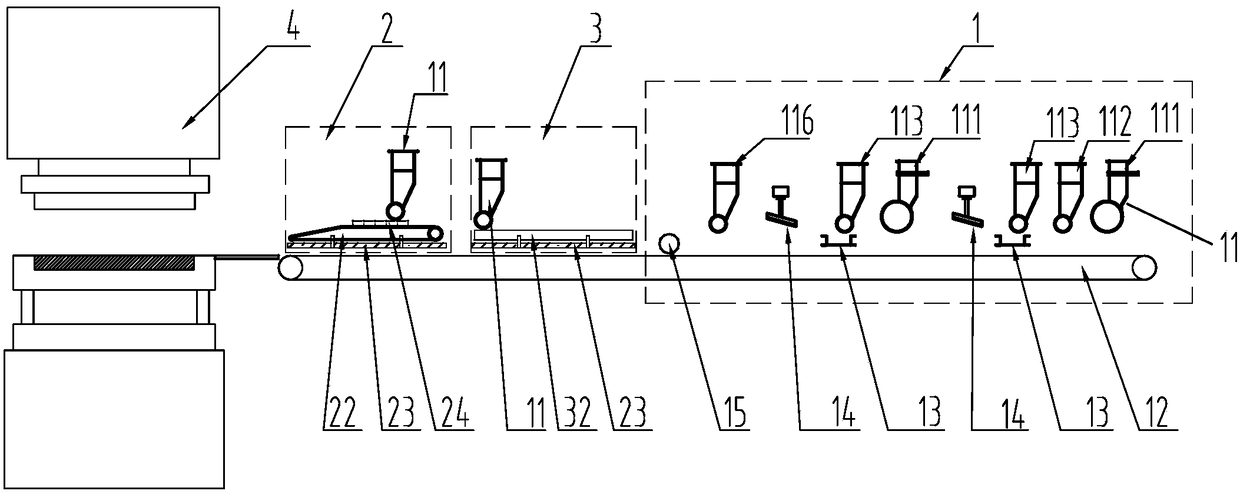

Embodiment approach 1

[0064] Step 1. Start the first three in the lower hopper 11 of the first powder drop conveying module 1, and drop the powder of predetermined color on the main belt 12 that accepts and transmits the raw material, and distribute powder with a predetermined thickness , during the relative movement of the molding device during the downcutting stop time and the carrier transmission, each slice of the first group of molding devices 14 blocks the predetermined pattern layout on the main belt 12 during the downcutting process, forming powder accumulation and pits , and then through the fourth and fifth lower hoppers, wherein the powder of the predetermined amount of predetermined color is filled, and then the second set of molding device 14 cuts and blocks, and finally filled into the predetermined color predetermined material in the sixth lower hopper A certain amount of powder is flattened by the powder leveling device 15 to form the first layer of pattern raw material and conveyed ...

Embodiment approach 2

[0068]Step 1. Start the first three in the lower hopper 11 of the first powder drop conveying module 1, and drop the powder of predetermined color on the main belt 12 that accepts and transmits the raw material, and distribute powder with a predetermined thickness , during the relative movement of the molding device during the downcutting stop time and the carrier transmission, each slice of the first group of molding devices 14 blocks the predetermined pattern layout on the main belt 12 during the downcutting process, forming powder accumulation and pits , and then filled with the powder of the predetermined color and predetermined amount in the fourth and fifth lower hoppers, and then through the cutting and blocking effect of the second group of molding devices 14, and finally filled into the predetermined color predetermined amount in the sixth lower hopper The powder material is formed the first layer of pattern raw material after being flattened by the powder leveling dev...

Embodiment approach 3

[0073] Step 1. The push frame 23 of the feeding module 3 drives the feeding grid 32 to move forward. The feeding grid here is a receiving type conveying grid, which accepts the raw materials falling from the upper lower hopper 11 during the moving process;

[0074] Step 2. After the accepting conveying grid accepts the laid raw materials, the push rack 23 drives the feeding grid 32 to push to the forming device. Descending, the predetermined raw material received by the conveying grid falls on the surface of the lower mold core of the mold cavity and falls into the mold cavity with the falling mold, and the push frame 23 returns. adobe;

[0075] Step 3: The push frame 23 returns to the initial position, the conveying grid continues to accept the raw materials of step 1, repeat the above step 2, and at the same time push the bricks pressed in the previous step out of the press, and transfer them to the drying machine under the conveying of the subsequent process. The kiln is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com