Anti-hydrogen packaging bag, manufacturing method thereof and combined package

A packaging bag and hydrogen blocking technology, which is applied in the field of packaging materials, can solve the problems of low shelf life and hydrogen permeability rate, and cannot guarantee the taste of hydrogen-containing food at the same time, and achieve the effect of simple preparation method, excellent barrier property, and extended shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

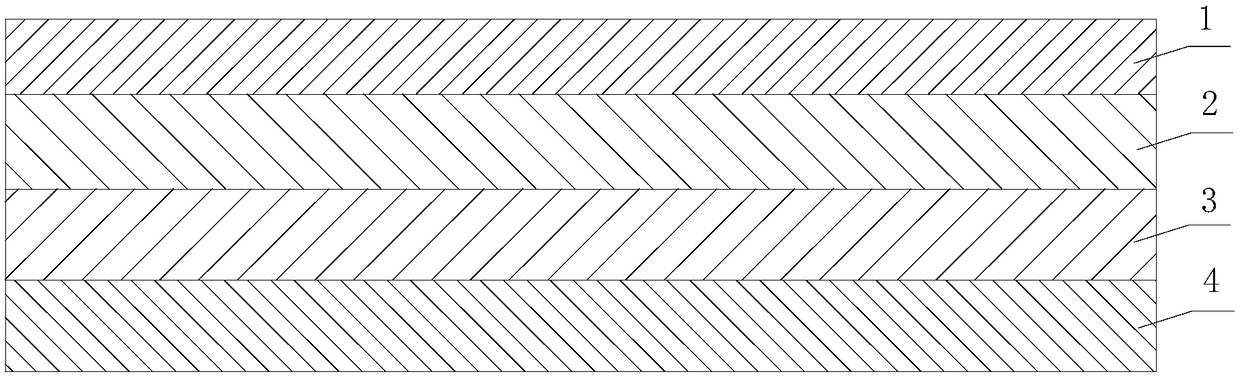

[0046] refer to figure 1 As shown, the hydrogen barrier packaging bag of this embodiment includes: a polyethylene terephthalate layer 1 , an aluminum film layer 2 , a nylon layer 3 and a polyethylene layer 4 , which are sequentially combined from outside to inside.

[0047] In the hydrogen barrier packaging bag of this embodiment, the polyethylene terephthalate layer 1 is used as the outermost layer, and the printing effect is better, the aluminum film layer 2 plays the role of blocking hydrogen, and the nylon layer 3 is used for stretch resistance and waterproof , The polyethylene layer 4 has good flexibility and fragrance retention.

[0048] In the hydrogen-blocking packaging bag of the present invention, the sequence of polyethylene terephthalate layer 1, aluminum film layer 2, nylon layer 3 and polyethylene layer 4 is selected from the outside to the inside, ensuring the hydrogen-containing liquid food. Fragrance will not penetrate the polyethylene layer 4, liquid will no...

Embodiment 2

[0070] The method for preparing the hydrogen-barrier packaging bag of this embodiment is used to prepare the hydrogen-barrier packaging bag of Example 1, comprising the following steps:

[0071] Prepare raw materials: prepare polyethylene terephthalate sheet with a thickness of 10-15 microns, prepare an aluminum film sheet with a thickness of 6-10 microns, prepare a nylon sheet with a thickness of 15-20 microns, prepare a thickness 100-120 micron polyethylene sheet;

[0072] Dry lamination: The polyethylene terephthalate sheet and the aluminum film sheet, the aluminum film sheet and the nylon sheet are respectively bonded with an adhesive by a dry lamination method.

[0073] Hot-melt lamination: bonding nylon sheets and polyethylene sheets by hot-melt lamination.

[0074] In the dry compounding step:

[0075] The mass ratio of the solid to water of the adhesive is 3:7, the amount used is 1.5-3.5g / ㎡, the compounding temperature is 70-90°C, the drying wind speed is 30-40m / s, a...

Embodiment 3

[0091] The combined package of this embodiment includes: an outer shell layer and the hydrogen barrier packaging bag of Embodiment 1, wherein the outer shell layer is arranged outside the polyethylene terephthalate layer 1 .

[0092] Specifically, the shell layer and the polyethylene terephthalate layer 1 are not bonded together.

[0093] The hydrogen-blocking packaging bag of Example 1 has a transverse and longitudinal tensile strength greater than 50 MPa, a peel strength greater than 6N / 15mm, and a heat-sealing strength greater than 80N / 15mm. In actual use, when the capacity of the hydrogen-resistant packaging bag is less than 25L, Reliable packaging can be guaranteed without adding an outer shell layer. However, when the capacity of the hydrogen-resistant packaging bag is greater than or equal to 25L, the packaging may be damaged when the hydrogen-resistant packaging bag is impacted by an external force, and reliable packaging cannot be guaranteed. , so it is necessary to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com