Nearby rotting method for greenhouse tomato wastes in autumn and winter seasons

A waste and tomato technology, applied in the field of vegetable waste recycling, can solve the problems of increased planting area of facilities, non-point source pollution, polluted water bodies, etc., and achieve the effect of reducing adverse effects, reducing large losses, and reducing transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

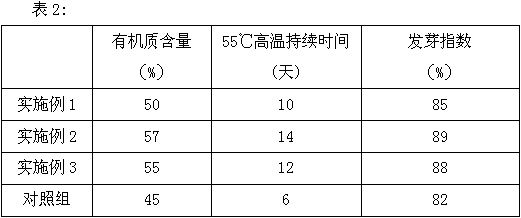

Embodiment 1

[0035] A method for nearby tomato waste in autumn and winter greenhouses to decompose, comprising the steps of:

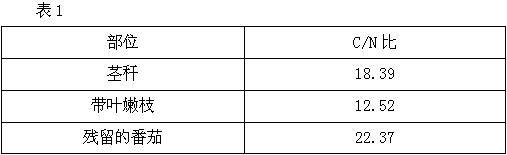

[0036] Step 1. Collect the tomato waste after harvesting the tomatoes in the greenhouse in autumn and winter, and divide the collected tomato waste into three parts: stems, leafy twigs and remaining tomatoes, and set aside;

[0037] Step 2: Cut the stalks and twigs with leaves into 2cm lengths and dry them in the sun for 2-5 days until the water content of the stalks and twigs with leaves is 60%. Twigs, spare;

[0038] Step 3. Soak the remaining tomatoes in a water bath at 70°C for 20 hours, then take out the soaked tomatoes, add 2 times the mass of the tomatoes to boiling water and then naturally cool down to crush them into a homogenate. After crushing the tomato homogenate, Tomato particle size is less than 1mm, get tomato homogenate, set aside;

[0039] Step 4. Mix the stems after drying in step 2 with the leafy twigs after drying. After mixing, add the tomat...

Embodiment 2

[0045] A method for nearby tomato waste in autumn and winter greenhouses to decompose, comprising the steps of:

[0046] Step 1. Collect the tomato waste after harvesting the tomatoes in the greenhouse in autumn and winter, and divide the collected tomato waste into three parts: stems, leafy twigs and remaining tomatoes, and set aside;

[0047] Step 2: Cut the stalks and twigs with leaves into 4cm lengths and dry them in the air for 2-5 days until the water content of the stalks and twigs with leaves is 70%. Twigs, spare;

[0048] Step 3: Soak the remaining tomatoes in a water bath at 80°C for 26 hours, then take out the soaked tomatoes, add water 5 times the mass of the tomatoes after boiling, and crush them into a homogenate. After crushing the tomato homogenate, Tomato particle size is less than 1mm, get tomato homogenate, set aside;

[0049] Step 4. Mix the stems after drying in step 2 with the leafy twigs after drying. After mixing, add the tomato homogenate prepared in...

Embodiment 3

[0055] A method for nearby tomato waste in autumn and winter greenhouses to decompose, comprising the steps of:

[0056] Step 1. Collect the tomato waste after harvesting the tomatoes in the greenhouse in autumn and winter, and divide the collected tomato waste into three parts: stems, leafy twigs and remaining tomatoes, and set aside;

[0057] Step 2: Cut the stalks and twigs with leaves into 3cm lengths and dry them in the sun for 2-5 days until the moisture content of the stalks and twigs with leaves is 65%. Twigs, spare;

[0058] Step 3. Soak the remaining tomatoes in a water bath at 75°C for 24 hours, then take out the soaked tomatoes, add 3 times the mass of the tomatoes to boiling water, and then naturally cool them down to form a homogenate. After the tomato homogenate is crushed, Tomato particle size is less than 1mm, get tomato homogenate, set aside;

[0059] Step 4. Mix the stems after drying in step 2 with the leafy twigs after drying. After mixing, add the tomat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com