Shape memory polymer network formation system of controllable heat and light two-stage reaction and preparation method of shape memory polymer network formation system

A memory polymer, two-stage technology, applied in the field of shape memory materials, can solve the problems of shape memory polymer network formation system structure uncertainty, narrow application range, etc., to improve mechanical properties and service life, increase crosslinking density, Resolving effects with ambiguous structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Specific embodiment 1: This embodiment describes a shape memory polymer network forming system with controllable heat and light two-stage reaction, and the shape memory polymer network forming system is composed of 20-40% of thiol, 20-40% of epoxy resin, 20-55% of acrylic resin, 0.1-2% of catalyst and 0.5-4% of photoinitiator.

specific Embodiment approach 2

[0019] Specific embodiment two: a preparation method of the shape memory polymer network forming system with controllable heat and light two-stage reaction described in specific embodiment one, the method includes the following steps, such as figure 2 Shown:

[0020] Step 1: Fully mix mercaptan, epoxy resin, and photoinitiator at a temperature of 25~150°C;

[0021] Step 2: Add a catalyst with a mass of 0.1-2% of the mixture obtained in Step 1, mix evenly, and react at a temperature of 0-50°C for 0.2-5h to obtain a prepolymer;

[0022] Step 3: Add acrylic resin and a catalyst with 0.1-2% mass of acrylic resin to the prepolymer, mix evenly, and react at 0-100°C for 1-120 hours to obtain an intermediate polymer;

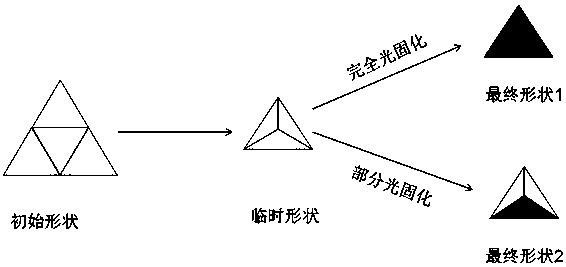

[0023] Step 4: Study the shape memory of the intermediate polymer obtained in Step 3: first determine the glass transition temperature of the intermediate polymer by DMA Tg 1 , Tg 1 -40~30℃, test the shape memory fixation rate of intermediate state polymers R f1...

Embodiment 1

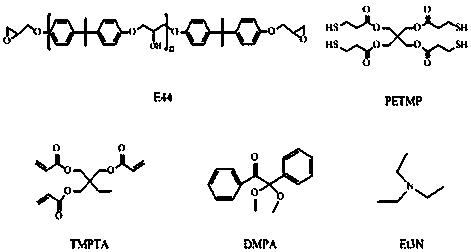

[0031]a Weigh 107 g of tetrakis(3-mercaptopropionic acid) pentaerythritol ester, 100 g of epoxy resin E44, 8.55 g of 2,2-dimethoxy-phenylacetophenone at 70°C and mix well, such as figure 1 Shown is a schematic diagram of the raw material structure used in this embodiment.

[0032] b After the mixture was cooled to room temperature, 1.72 g of triethylamine was added, mixed uniformly, and reacted at 35° C. for 60 min to obtain a prepolymer.

[0033] c Add 78 g of trimethylolpropane triacrylate and 0.63 g of triethylamine to the prepolymer, and react at room temperature for 48 hours to obtain an intermediate state polymer.

[0034] d The resulting intermediate state polymer was subjected to shape memory studies: first the glass transition temperature of the first stage polymer was determined by DMA Tg 1 , Tg 1 At 28°C, test the shape memory fixation rate of the polymer in the first stage R f1 and shape memory recovery rate R r1, R f1 and R r1 91% and 93% respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com