Environment-friendly water-based laminating adhesive as well as preparation method and bonding technology thereof

An environment-friendly, adhesive technology, applied in adhesive heating bonding methods, adhesives, mineral oil hydrocarbon copolymer adhesives, etc., can solve the problem of restricting the use of water-based adhesives, which cannot be used by ordinary water-based adhesives Solve problems such as adhesion and slow volatile solvents to achieve good adhesion and peel strength, large market application value, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

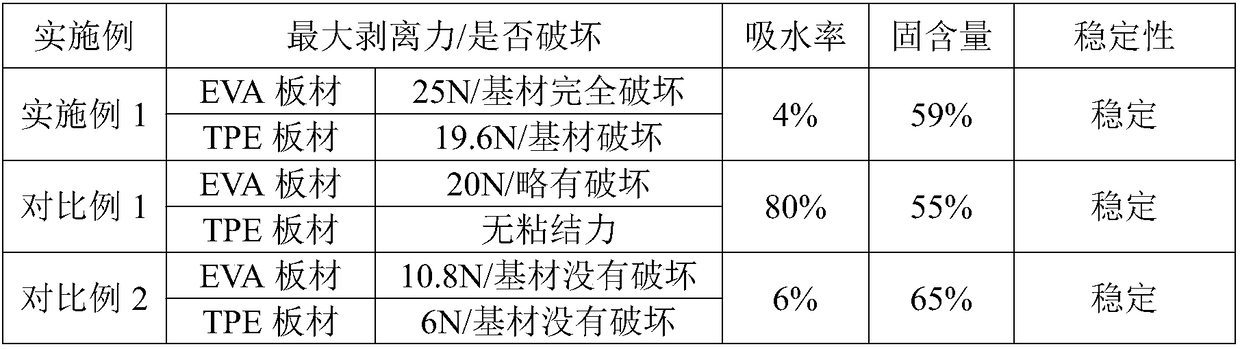

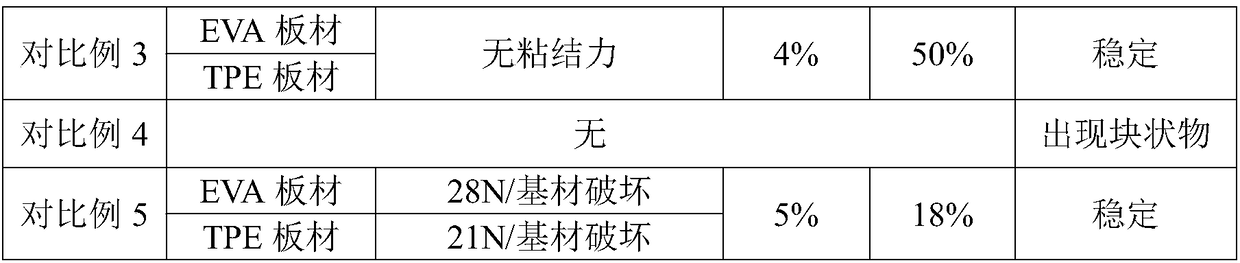

Embodiment 1

[0033] Example 1: Add 67 parts of ethylene-vinyl acetate emulsion (model DA-102H) and 23 parts of aqueous terpene phenolic dispersion into a there-necked flask equipped with a stirrer, stir evenly, and add 9 parts of petroleum resin , add 1 part of defoamer and thickener mixture, stir for 15 minutes and mix well, then take it out. Apply the prepared adhesive directly on the EVA and TPE foam boards, then place it in an oven at 60°C for 2 minutes, take it out, apply cloth, pressurize, place it in an oven at 75°C after pressurization, and heat it for 5 minutes , take out the pressurizing device, and dry at 75°C until the surface of the material is dry.

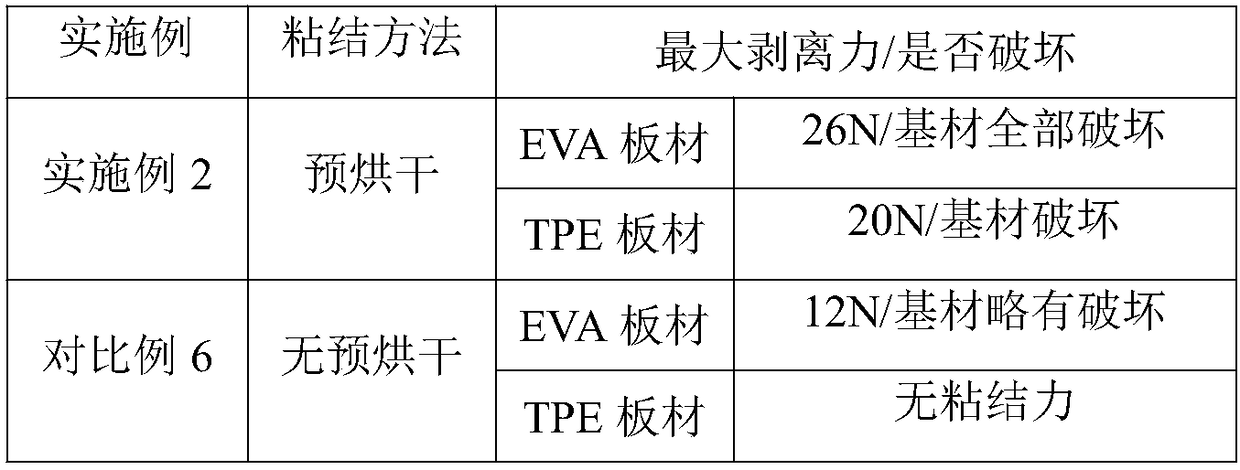

Embodiment 2

[0043] Example 2: Add 69 parts of ethylene-vinyl acetate emulsion (model is DA-102H) weighed in the there-necked flask equipped with a stirrer, 20 parts of water-based terpene phenolic dispersion, stir evenly, add 10 parts of petroleum resin , add 1 part of defoamer and thickener mixture, stir for 15 minutes and mix well, then take it out. Apply the prepared adhesive directly on the EVA and TPE foam boards, then place it in an oven at 60°C for 2 minutes, take it out, apply cloth, pressurize, place it in an oven at 75°C after pressurization, and heat it for 5 minutes , take out the pressurizing device, and dry at 75°C until the surface of the material is dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com