A kind of magnetron sputtering optical coating equipment and coating method with vacuum mechanical arm

A magnetron sputtering, optical coating technology, applied in sputtering coating, vacuum evaporation coating, ion implantation coating and other directions, can solve the problems of affecting output, less coating, low target coating efficiency, etc., to achieve loading and unloading materials The effect of short time, improved stability and reduced pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

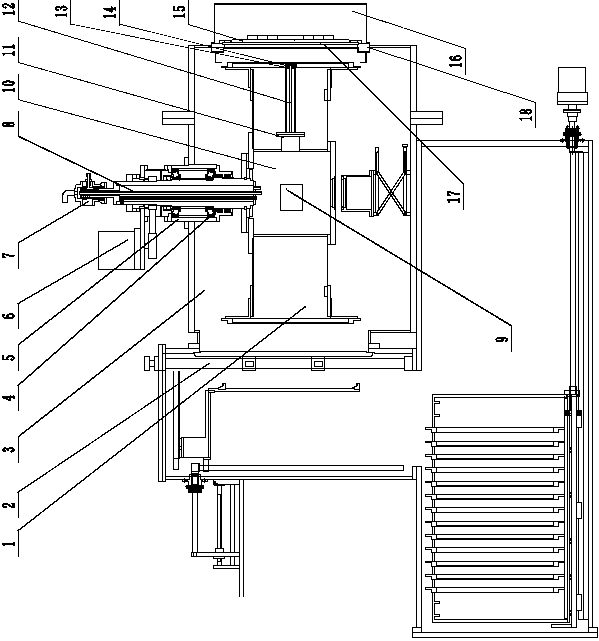

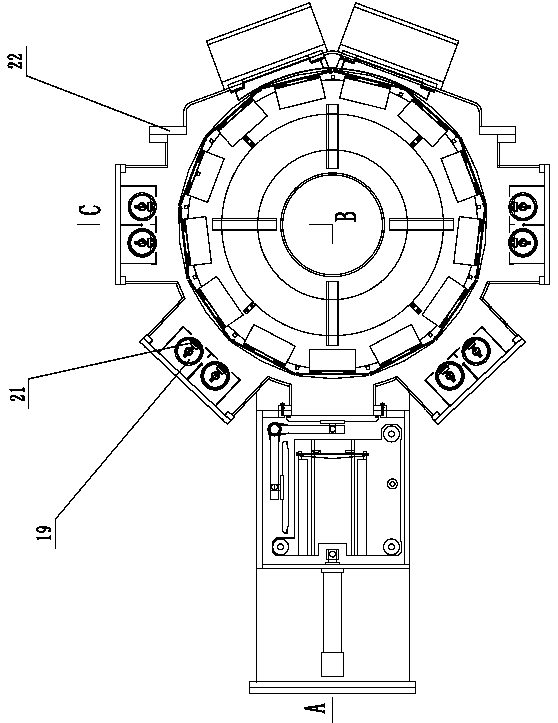

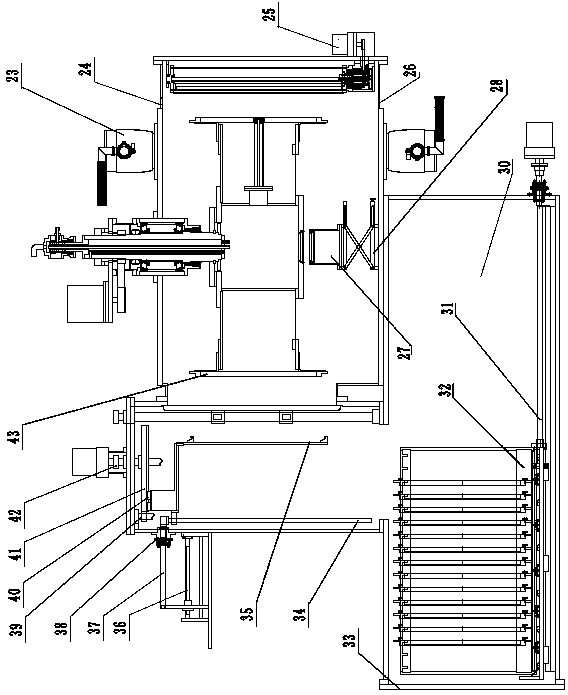

[0032] The magnetron sputtering optical coating equipment and the magnetron sputtering optical coating method involved in the present invention will be described below with reference to the accompanying drawings.

[0033] Such as Figures 1 to 3As shown, a magnetron sputtering optical coating equipment with a vacuum manipulator includes a vacuum coating chamber 3, a vacuum manipulator chamber 30, a magnetron sputtering target assembly 19, and a vertical rotating drum 1; the vacuum coating chamber 3 is a vertical Type cylindrical structure, upper and lower ends are provided with an upper cover 24 and a lower cover 26, and side doors 22 are arranged on the side; the vertical cylindrical side wall is also provided with an interface connected with the vacuum manipulator chamber 30; The vertical rotating drum 1 is located in the vacuum coating chamber 3 and rotates around the vertical axis. The center of the vertical rotating drum 1 is provided with a sealed box 10. The upper part ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com