Connecting structure of semiconductor microwave generator

A microwave generator and connection structure technology, which is applied in microwave heating, heating fuel, lighting and heating equipment, etc., can solve the problems that the discharge tube is easily corroded, affects the operation of the equipment, and the plasma is unstable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

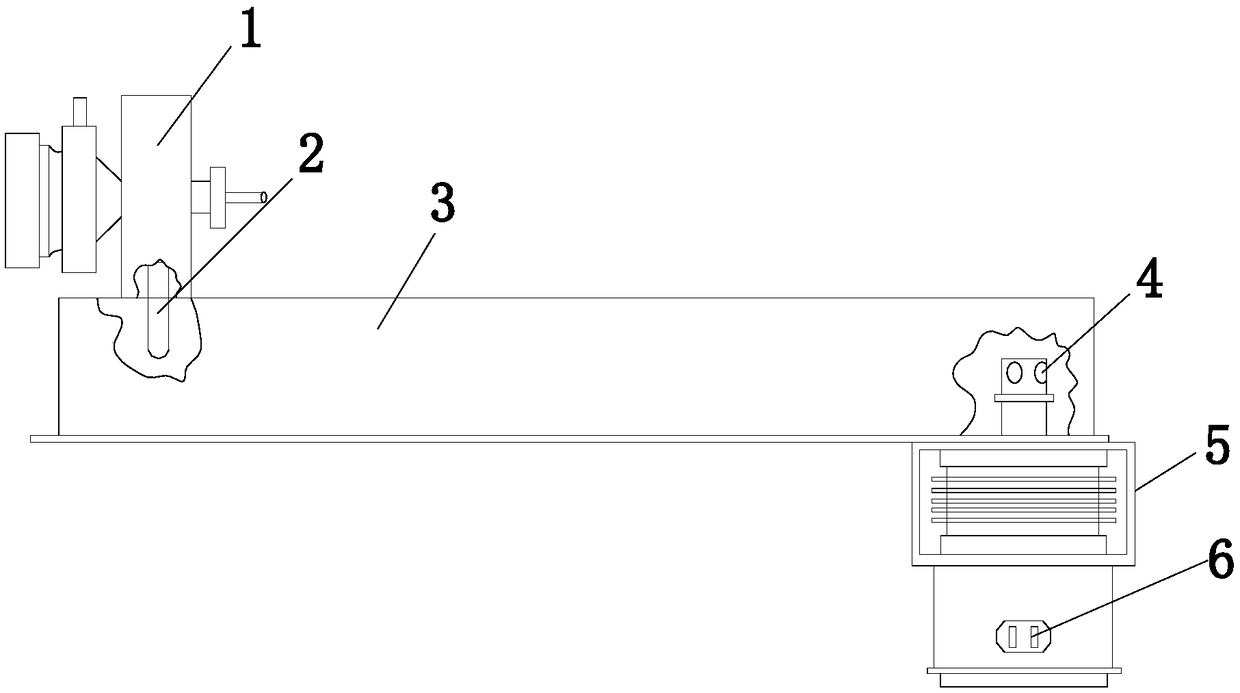

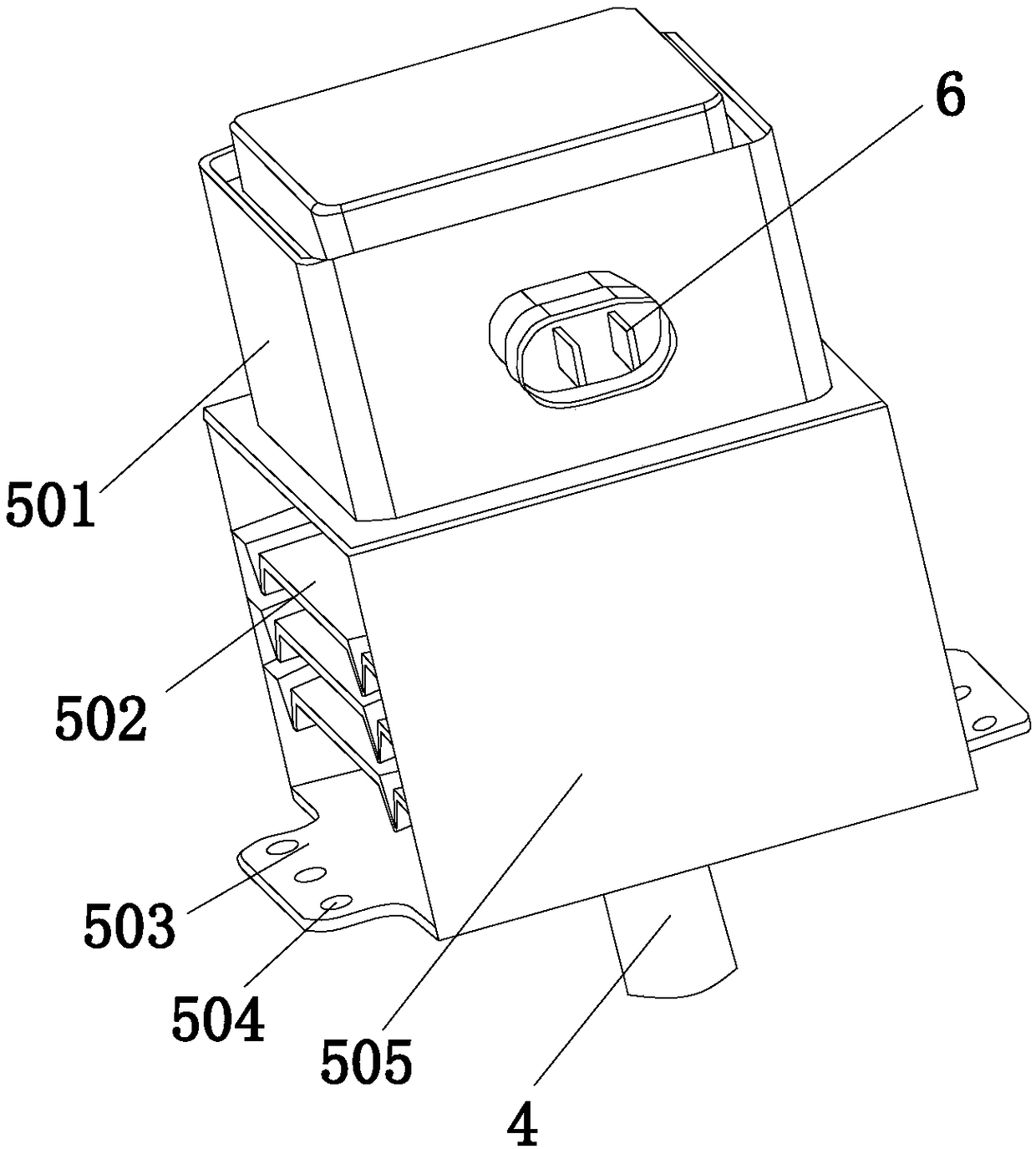

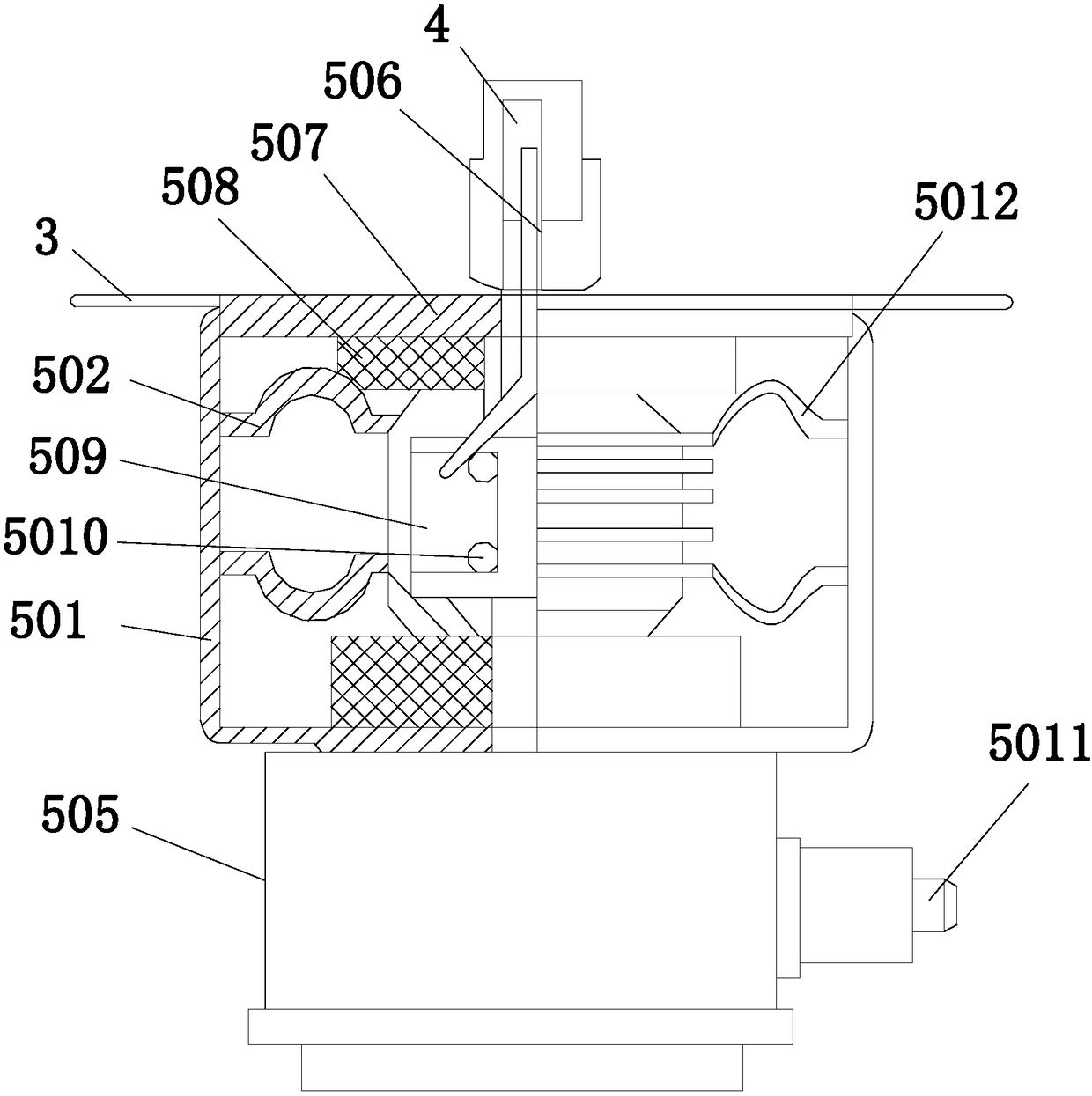

[0031] see Figure 1-Figure 9 , the present invention provides a semiconductor microwave generator connection structure, which structure includes a resonant cavity 1, a resonant cavity antenna 2, a waveguide 3, an antenna 4, a semiconductor microwave generator 5, and a power interface 6, and one end of the waveguide 3 passes through The resonant cavity antenna 2 is connected with a resonant cavity 1, the resonant cavity 1 is installed in the microwave oven through a hinge provided and fixedly connected with screws, the other end of the waveguide 3 is equipped with a semiconductor microwave generator 5, and the resonant cavity Cavity antenna 2 adopts signal connection with antenna 4 through waveguide 3, and described power supply interface 6 is welded on the outer surface of the lower end of semiconductor microwave generator 5, and described semiconductor microwave generator 5 is composed of energy exporter 501, heat sink 502, chassis 503 , threaded hole 504, generator housing ...

Embodiment 2

[0034] see Figure 1-Figure 10 The lead-out cable 5011 is sequentially provided with a core wire 50111, a core wire insulation layer 50112, a first semiconductor layer 50113, an insulation layer 50114, a second semiconductor layer 50115, a metal shielding layer 50116, and a yarn wrap protection layer 50117 from inside to outside. The inside of the first semiconductor layer 50113 is evenly installed with three core wires 50111 and surrounds them to form a triangular structure. The outer surface is laminated with a second semiconductor layer 50115, a metal shielding layer 50116, and a yarn-wrapped protective layer 50117 in sequence.

[0035] The core wire insulation layer 50112, the first semiconductor layer 50113, the insulation layer 50114, the second semiconductor layer 50115, the metal shielding layer 50116, and the gauze protective layer 50117 provided with the outgoing cable 5011 can effectively prevent the equipment from being affected by the surrounding environment , un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com