Special double-rotary worktable for cradle short-arc compound machining center

A technology of compound machining center and double rotary table is applied in the field of short arc, which can solve the problems of large material removal, difficult-to-machine materials, and long manufacturing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

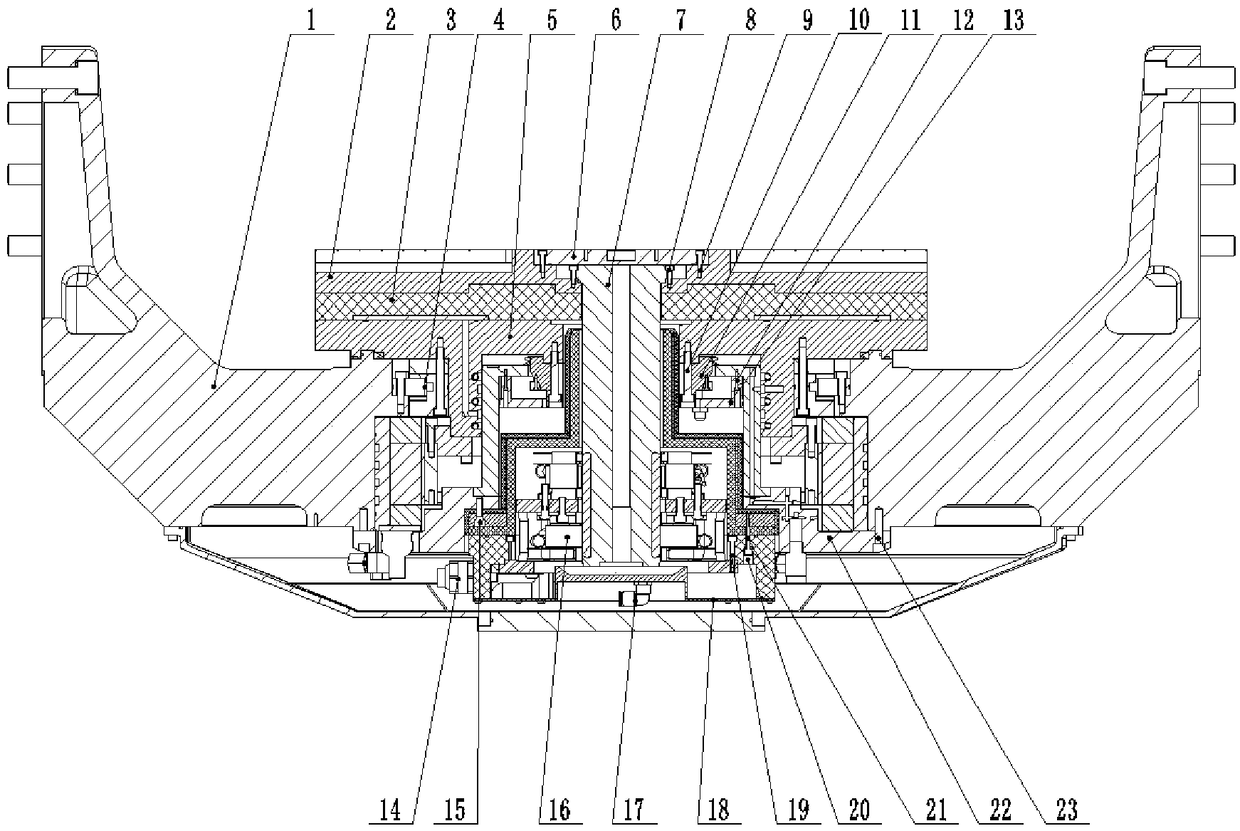

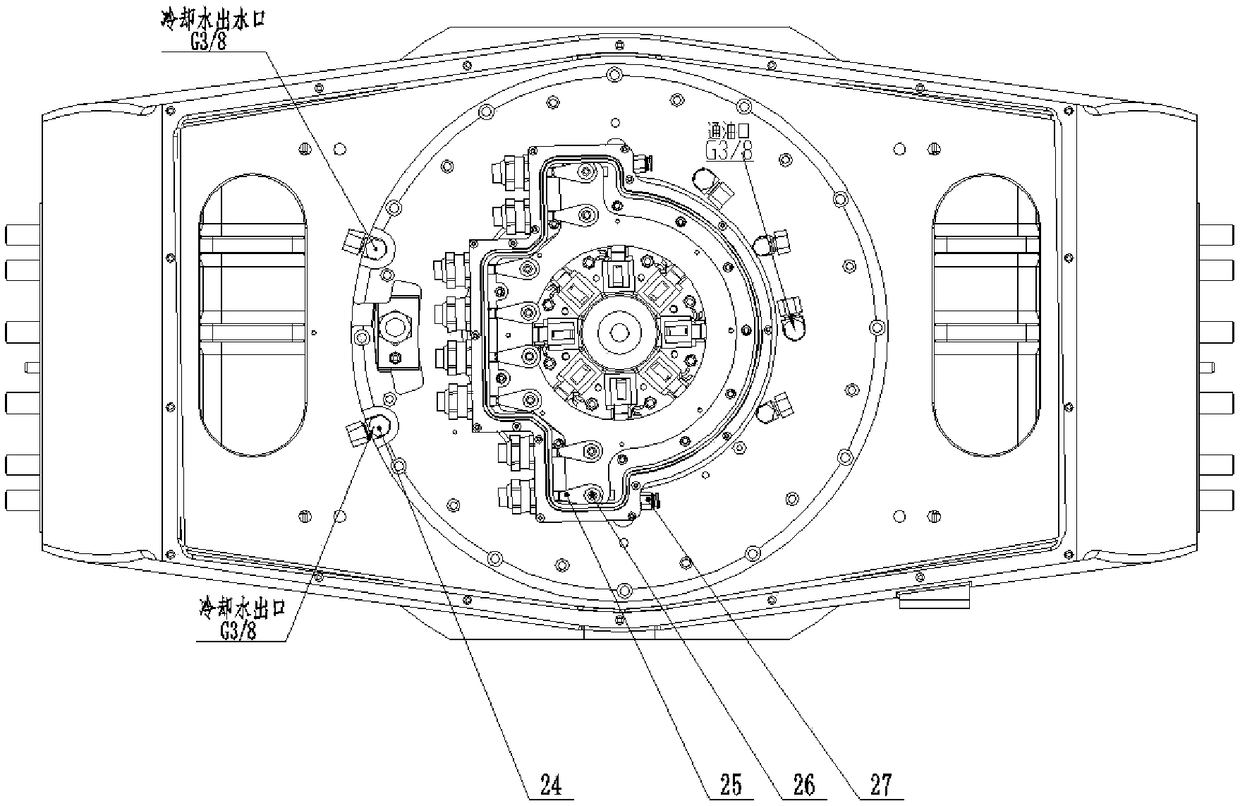

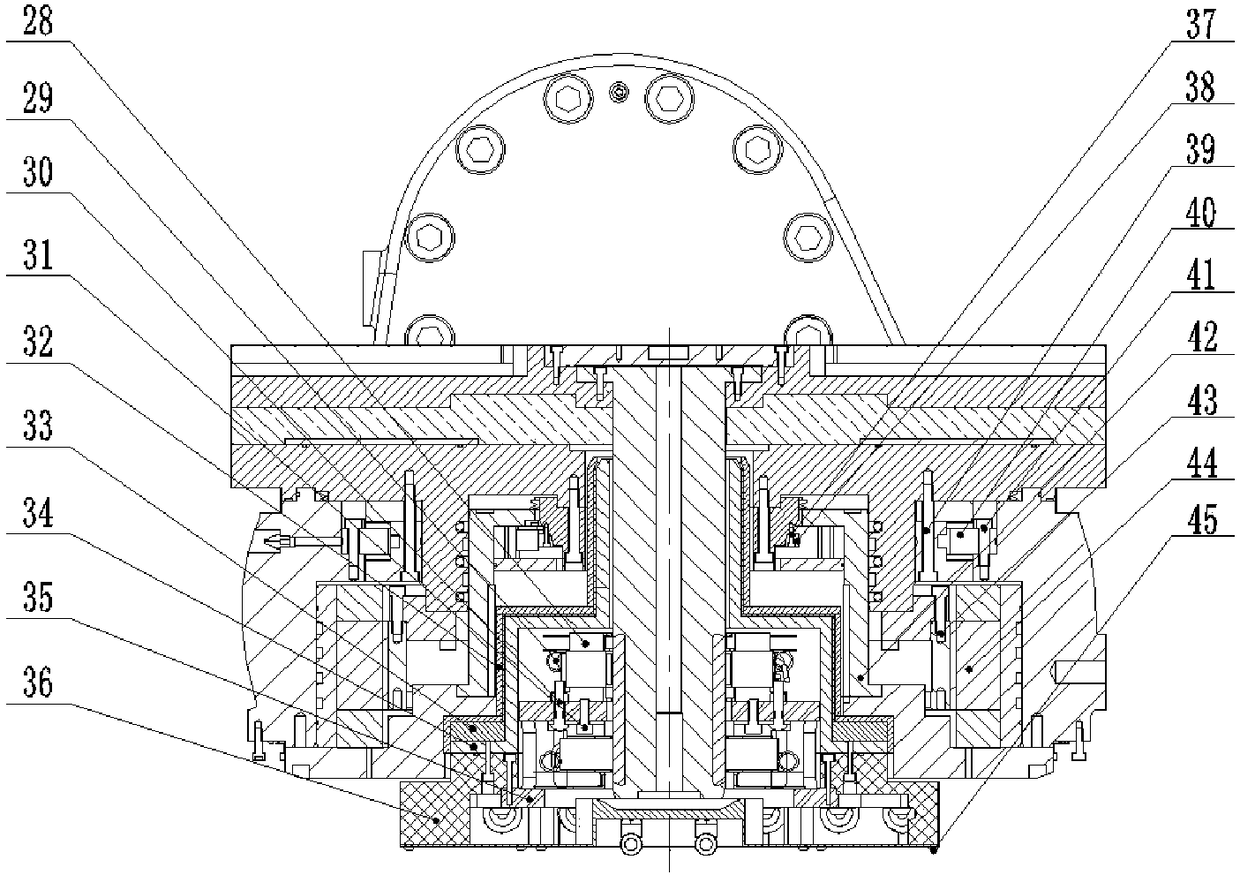

[0022] The technical solution of the present invention will be described in detail below with reference to the drawings.

[0023] Such as Figure 1-3 As shown, this embodiment discloses a cradle-type short-arc composite machining center dedicated double-rotation workbench, including a cradle swing frame 1 installed in cooperation with an A-axis torque motor, and a workbench mounting base 5 installed on the cradle swing frame 1 , The workbench installation base 5 is sequentially equipped with a marble sandwich 3 and a casting workbench 2. The anode spindle 7 is installed on the casting workbench 2 through the first hex socket bolt 8, and the workbench sealing cover 6 is installed through the second hex socket bolt 9. On the casting work surface. The YRT turntable bearing 4 is installed on the cradle swing frame 1 by the twelfth hexagon socket bolt, and the workbench mounting base 5 is connected with the inner ring of the YRT turntable bearing 4 by the eleventh hexagon socket bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com