Eddy flow abrasion-resistant coal dust gasification furnace

A gasifier and anti-wear technology, which is applied in the field of coal gasification, can solve problems such as affecting the efficiency and quality of gas output of the gasifier, insufficient combination of steam, damage to the structure of the gasifier, etc., so as to prevent heat loss, ensure gas output efficiency and Quality, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

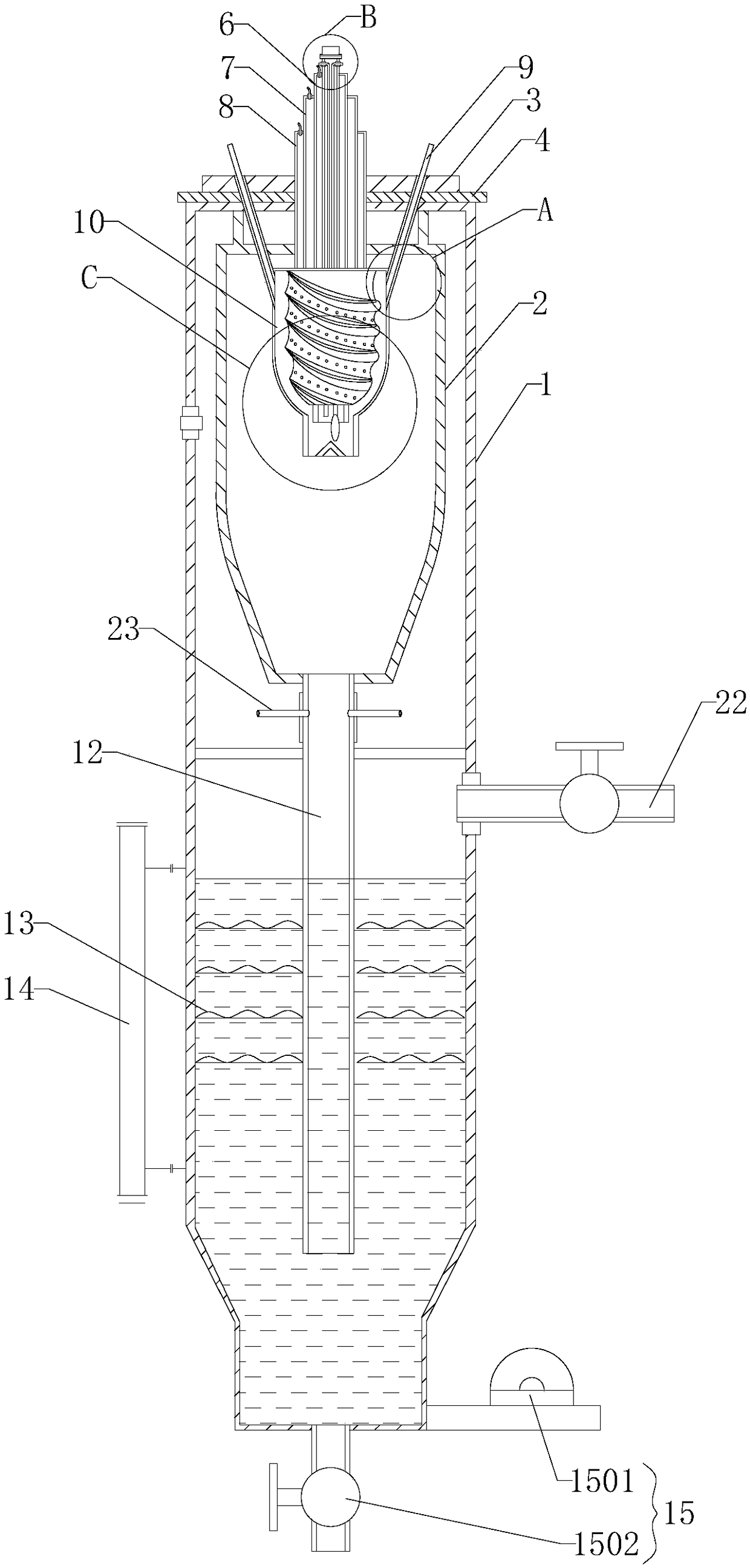

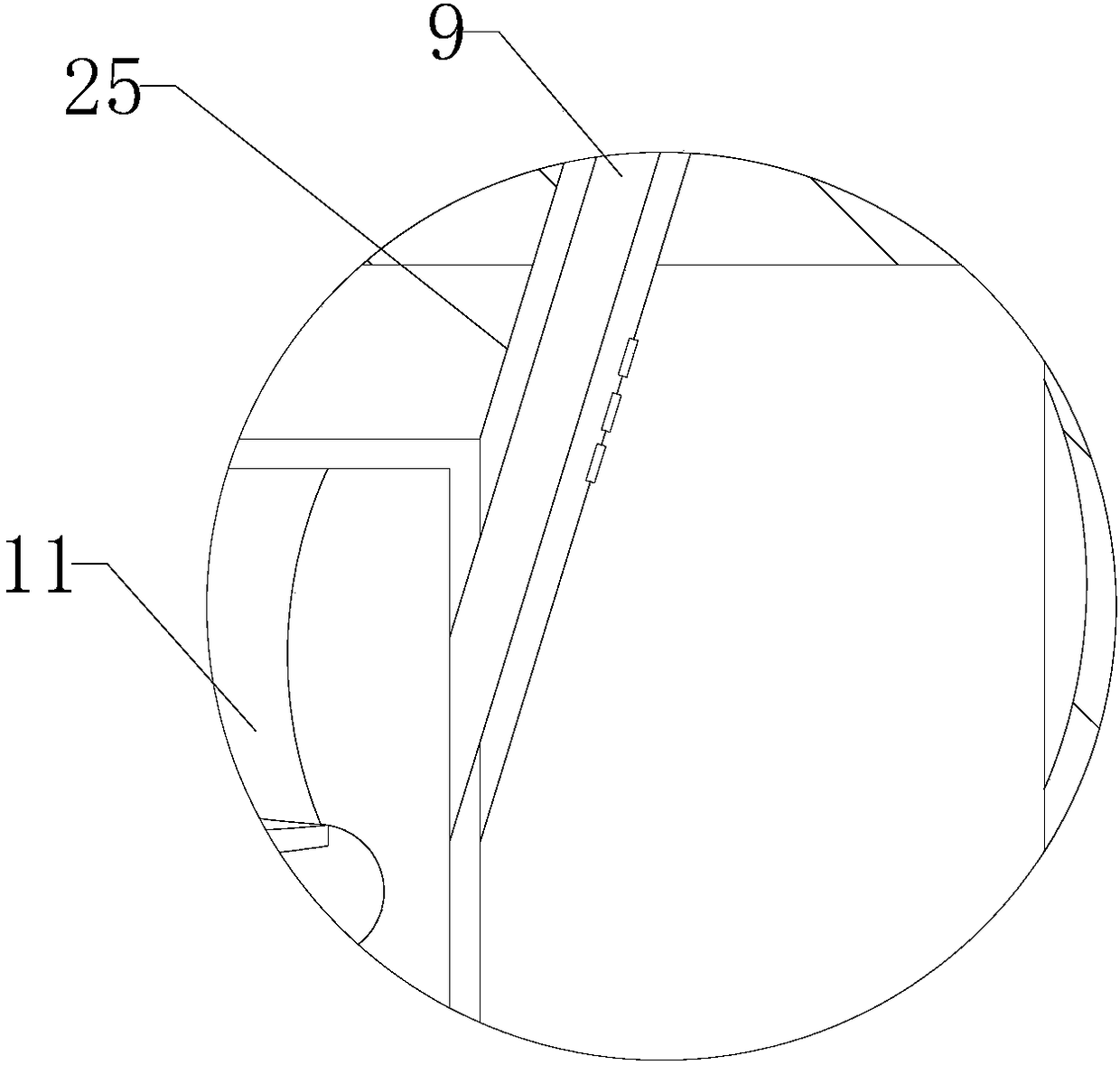

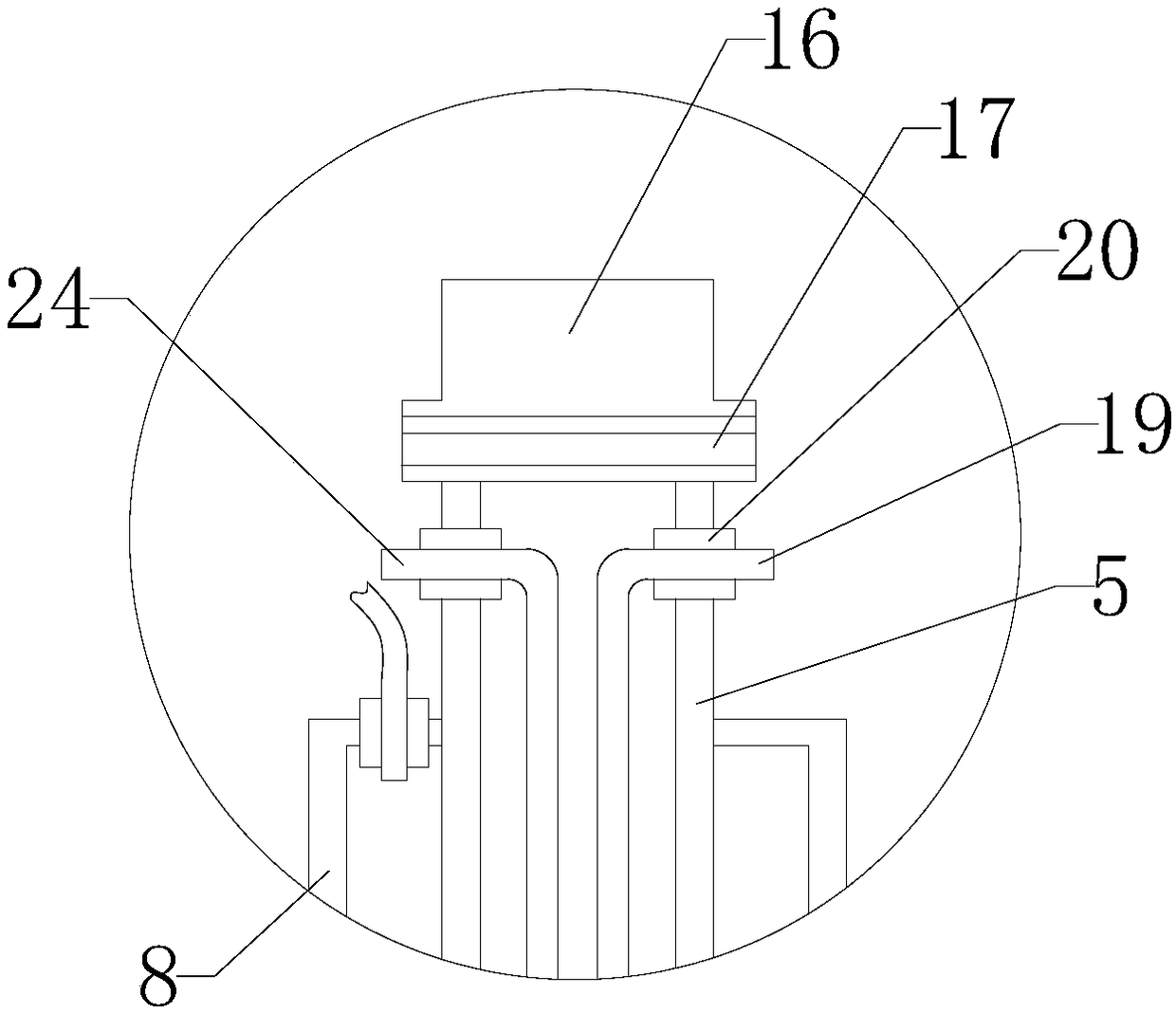

[0043] Such as figure 1 — Figure 8 As shown, this embodiment discloses a swirling anti-wear pulverized coal gasifier, which includes a furnace body 1 made of 316L+15CrMoR material, the upper end of the furnace body 1 is provided with a flange 4, and the furnace body 1 includes mutually isolated The upper cavity and the lower cavity, the upper cavity is provided with a water-cooled wall 2 connected to the flange 4, the water-cooled wall 2 encloses a closed combustion chamber, the flange 4 is provided with a burner assembly connected to the combustion chamber, and the flange 4 There is also a pulverized coal delivery pipe 9 for sending pulverized coal into the burner assembly, a downcomer 12 connected to the lower chamber is provided at the lower end of the combustion chamber; a process gas outlet 22 is provided at the upper part of the lower chamber, and a There is a waste disposal device 15 .

[0044] In this embodiment, there is an annular gap of 2 cm to 5 cm between the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com