Semiconductor laser material passivation method

A laser and semiconductor technology, applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve problems such as surface residues, poor vacuum environment, surface pollution, etc., reduce surface state density and non-radiative recombination centers, and improve optical performance , to avoid the effect of spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

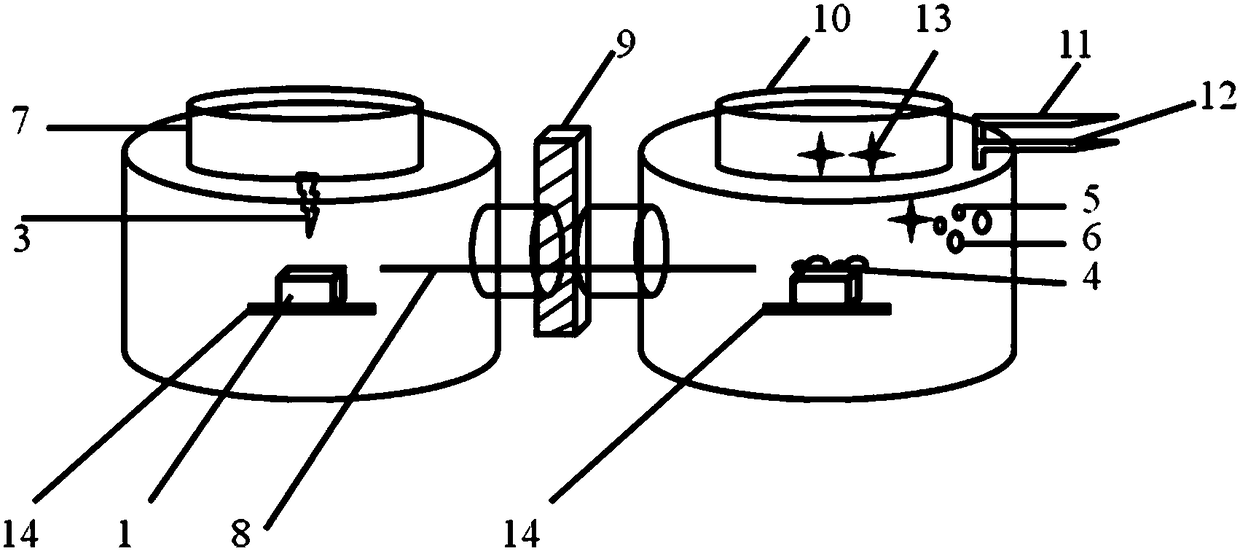

[0012] The following is a further detailed description of the semiconductor laser material passivation method proposed by the present invention, specifically the technical solution for the processing method of the cavity surface material of the semiconductor laser resonator cavity, by using the drawings and specific embodiments.

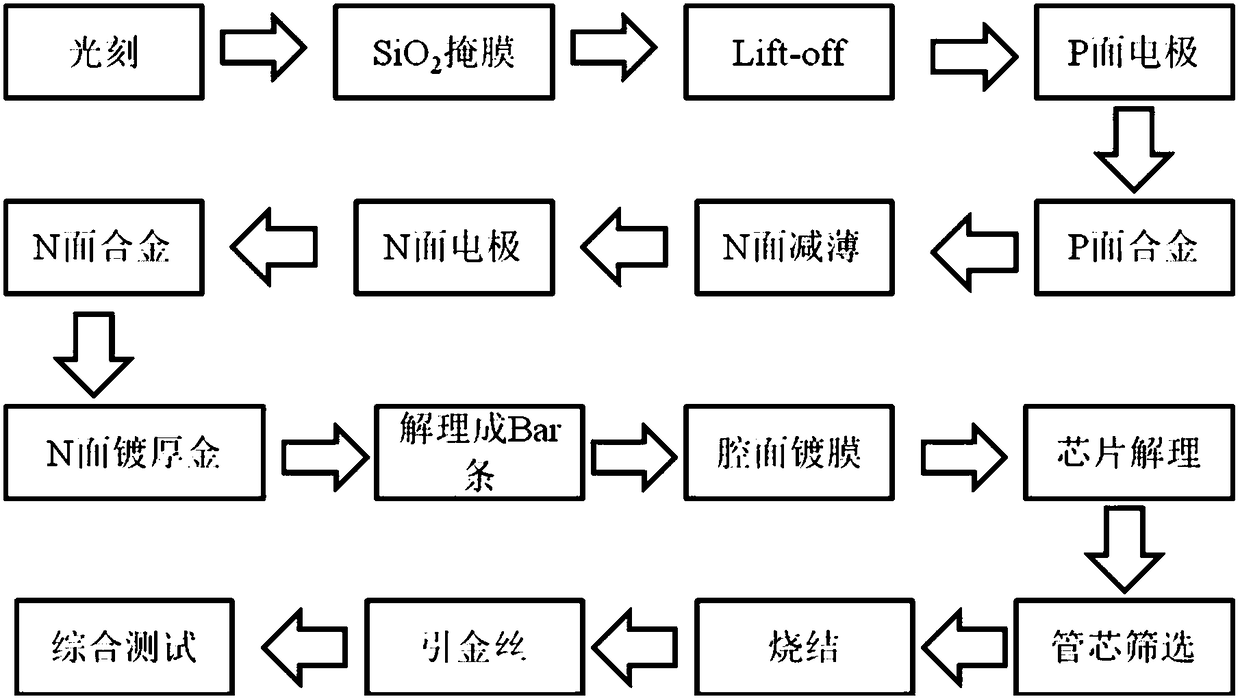

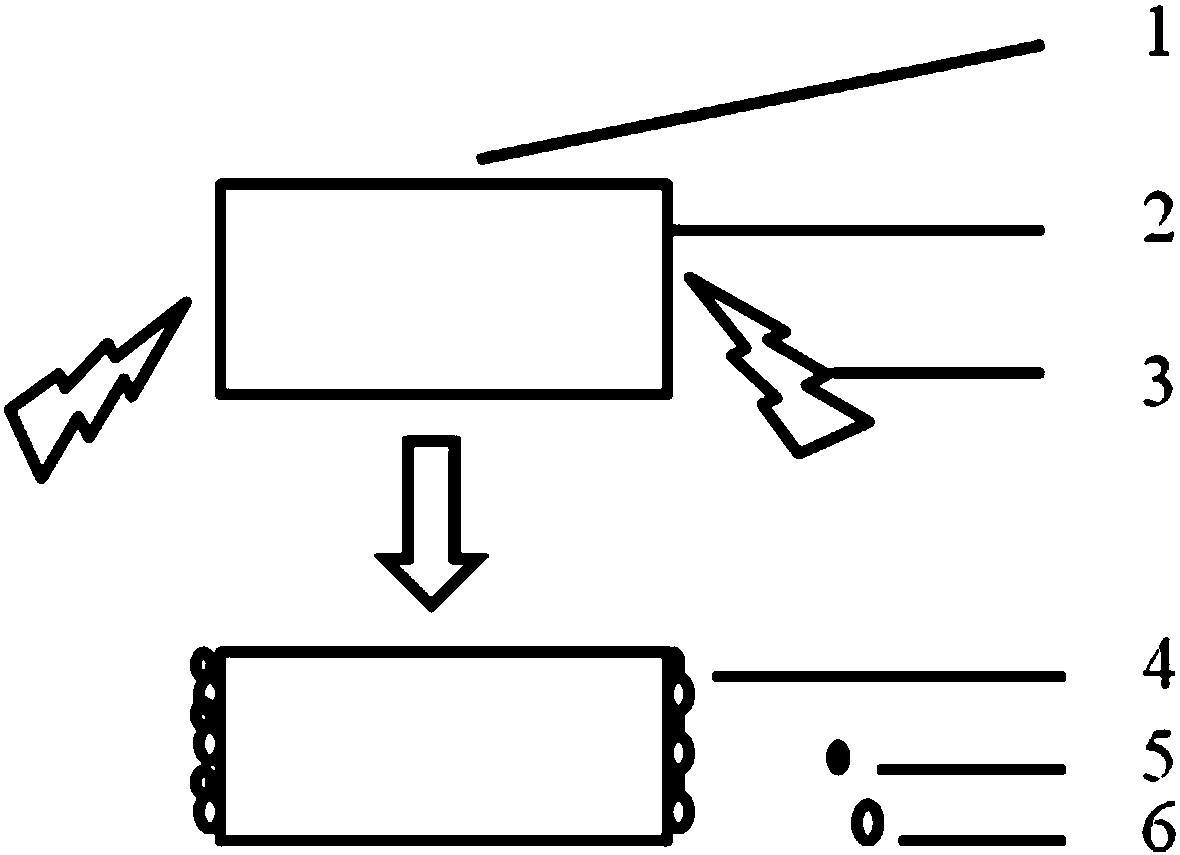

[0013] The present invention proposes a semiconductor laser material passivation method, the method first carries out ion bombardment cleaning to the cavity surface of the semiconductor laser cavity, and then uses ALD technology to deposit a passivation layer on the cavity surface of the cleaned semiconductor laser cavity to improve the efficiency of the semiconductor laser cavity. The cavity surface is protected, and the method mainly includes 3 steps: 1. The semiconductor laser epitaxial wafer is cleaved into Bar strips; 2. The semiconductor laser Bar strips are entered in the semiconductor laser resonator cavity surface processing device proposed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com