Production of hydrocarbon fuels from plastics

A technology for hydrocarbon fuels and plastics, used in liquid carbonaceous fuels, fuels, products, etc., can solve the problems of insufficient engine purity, unsatisfactory heat transfer coefficient, and limited feasibility of diesel extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

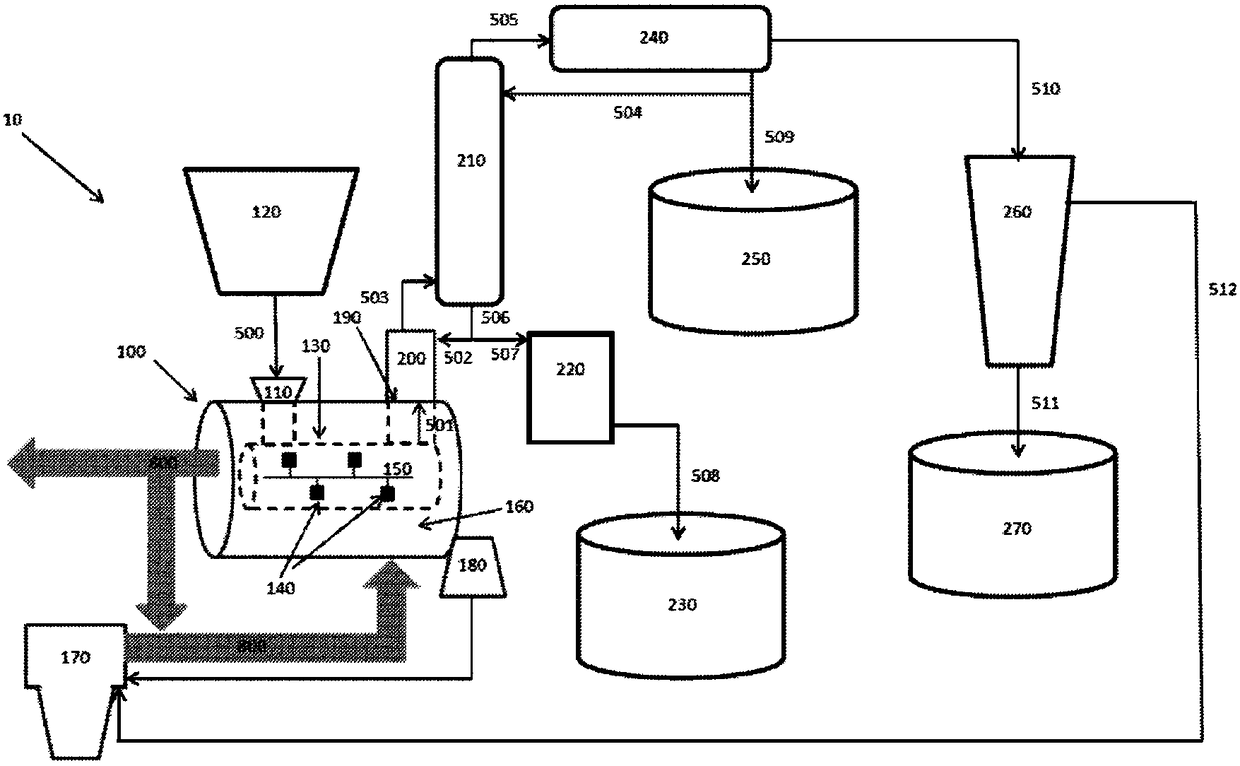

[0101] refer to figure 1 , provides a system 10 for converting plastics into hydrocarbon fuels such as diesel, gasoline and liquefied petroleum gas (LPG). The classification of hydrocarbon fuels is mainly determined by the chain length range of the hydrocarbons in the fuel mixture, for example diesel hydrocarbons usually range from C10-C25, gasoline hydrocarbons are C4-C12 and liquefied petroleum gas (LPG) usually contains propane ( C 3 h 8 ) and butane (C 4 h 10 )mixture.

[0102] System 10 includes plastic feedstock 500 supplied to kiln 100 . Plastic feedstock 500 may be any plastic material formed from long-chain organic polymers, such as waste plastic material (such as plastic packaging or car tires). Prior to introduction into the kiln 100, the plastic feedstock 500 may be pretreated, such as crushed or shredded to improve handling and surface area of the plastic feedstock, or dried to minimize the amount of water introduced into the system. Plastic raw material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com