Bio-fiber for cigarette filter tips and preparation method of bio-fiber

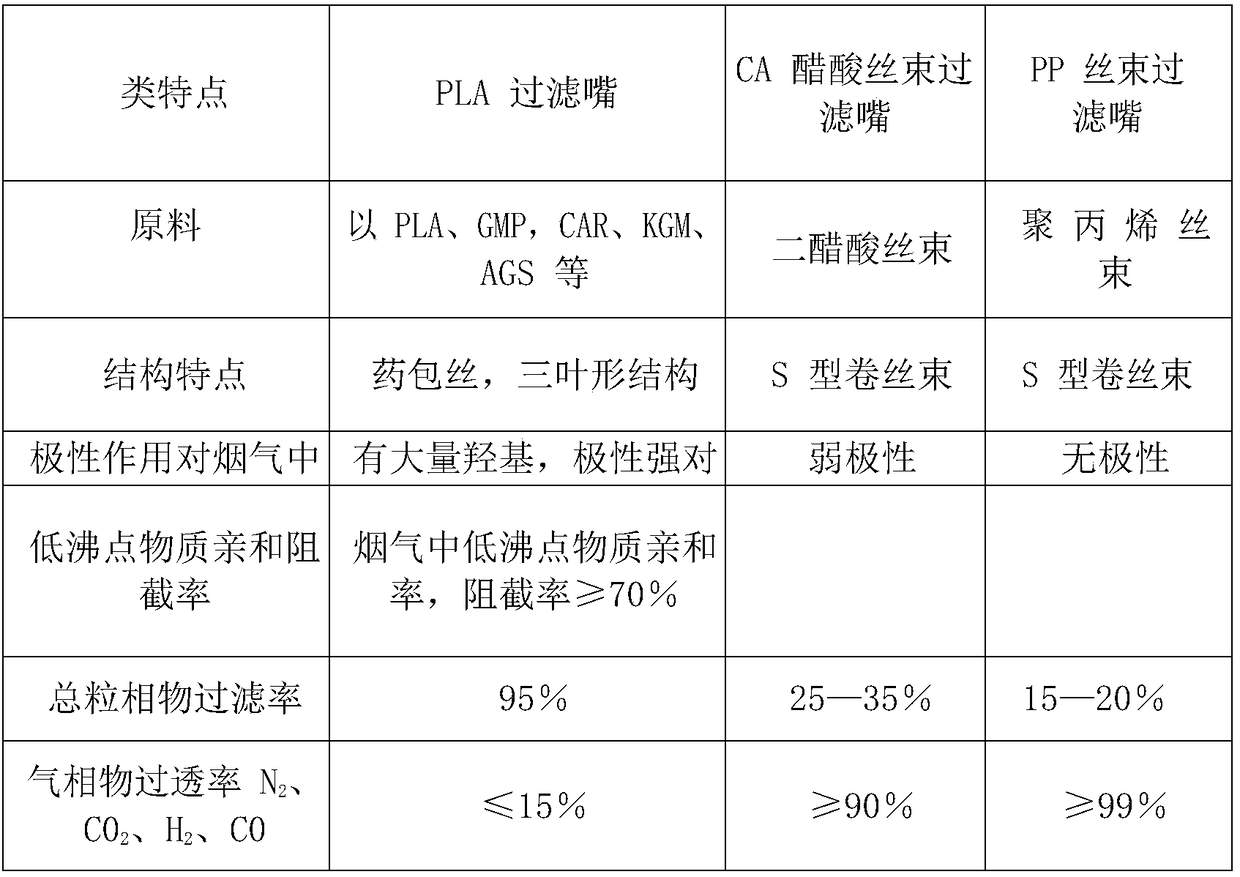

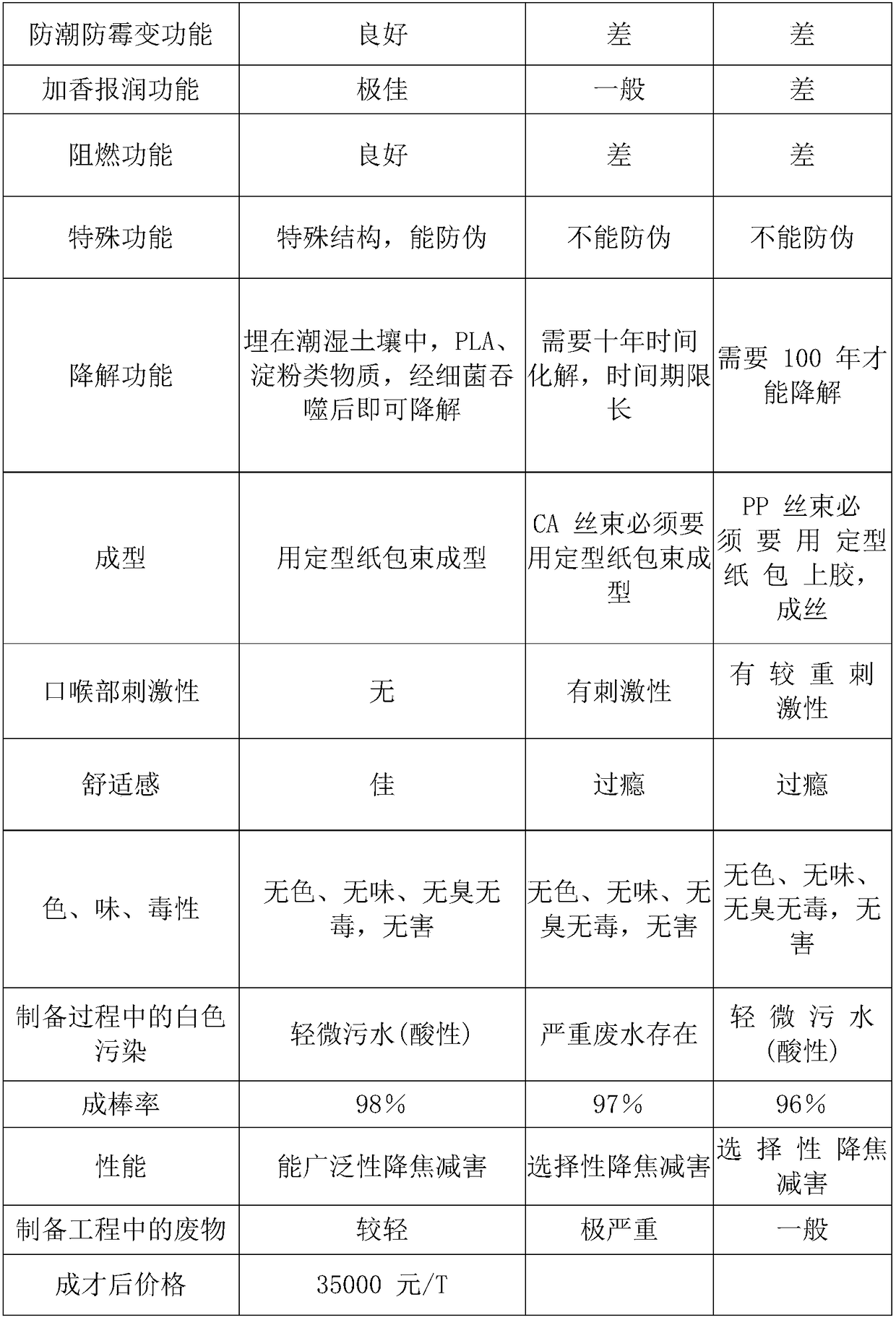

A bio-fiber and filter technology, applied in e-liquid filter, application, tobacco and other directions, can solve the problems of low adsorption capacity, limited filtration performance, and no tapioca starch bio-fiber, etc., and achieve the effect of excellent effect and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing biological fibers for cigarette filters, comprising the following steps:

[0026] (1) Mixing: put 10Kg of canna starch and 20Kg of tapioca starch in the mixer, and fully mix for 40 minutes at a speed of 16 rpm;

[0027] (2) Mixing material: pour 7Kg of cigarette gum into the blender and continue stirring for 30 minutes;

[0028] (3) Molding: The stirred material is poured into the molding machine, and the material is extruded from the ejection port by screw extrusion at a speed of 170°C and 380 rpm, and then enters the air cooling system for cooling at a temperature of 16°C. Put the cooled fiber filament into the crimping machine for crimping, packing, and it is ready.

Embodiment 2

[0030] A method for preparing biological fibers for cigarette filters, comprising the following steps:

[0031] (1) Mixing: put 9Kg of plantain taro starch and 21Kg of tapioca starch in the mixer, and fully mix for 42 minutes at a speed of 15 rpm;

[0032] (2) Mixing material: pour 6Kg of cigarette glue into the blender and continue stirring for 32 minutes;

[0033](3) Molding: The stirred material is poured into the molding machine, and the material is extruded from the ejection port by screw extrusion at a speed of 160°C and 400 rpm, and then enters the air cooling system for cooling at a temperature of 15°C. Put the cooled fiber filament into the crimping machine for crimping, packing, and it is ready.

Embodiment 3

[0035] A method for preparing biological fibers for cigarette filters, comprising the following steps:

[0036] (1) Mixing: put 8Kg of canna starch and 22Kg of tapioca starch in the blender, and fully mix for 44 minutes at a speed of 14 rpm;

[0037] (2) Mixing material: pour 5Kg of cigarette glue into the blender and continue stirring for 34 minutes;

[0038] (3) Molding: The stirred material is poured into the molding machine, and the material is extruded from the ejection port by screw extrusion at a speed of 150°C and 420 rpm, and then enters the air cooling system for cooling at a temperature of 14°C. Put the cooled fiber filament into the crimping machine for crimping, packing, and it is ready.

[0039] The invention uses renewable non-food crops as raw materials, which are green, environmentally friendly, low-carbon, degradable, and resource-renewable, and form an industrial chain from planting to processing, which promotes the development of the canna and cassava indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com