Magnetic-force material-pushing-type rapid decolorization device for producing epoxy soybean oil plasticizer

A technology of epoxidized soybean oil and plasticizer, applied in feeding device, chemical/physical/physical-chemical fixed reactor, chemical/physical/physical-chemical process, etc., can solve the problem of poor decolorization effect of epoxidized soybean oil, Can not fundamentally remove pigment, can not improve the decolorization effect and other problems, achieve the effect of obvious decolorization effect and decolorization efficiency, improve decolorization effect and decolorization efficiency, and good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

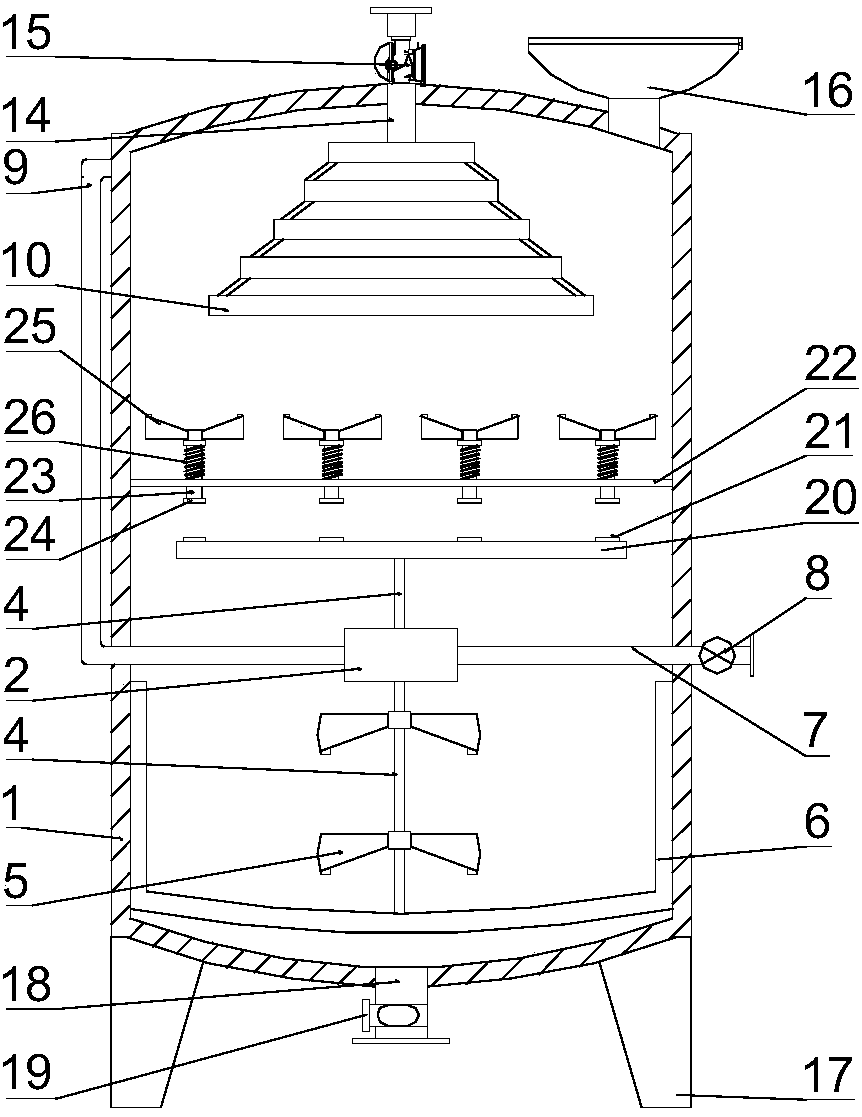

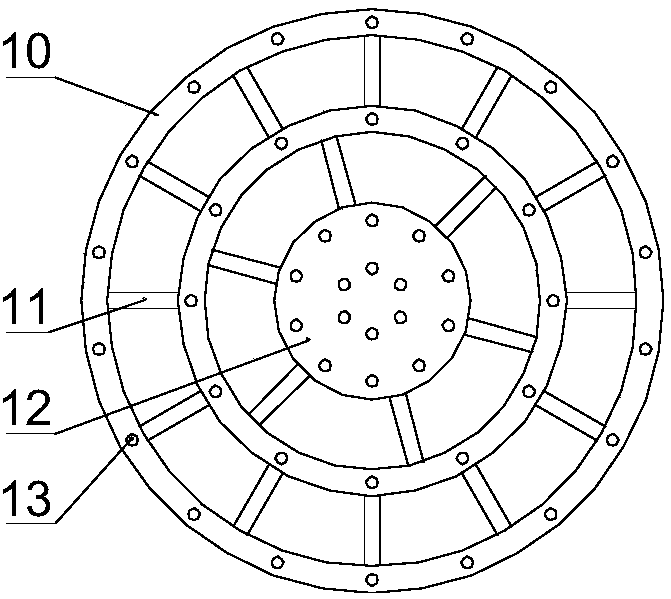

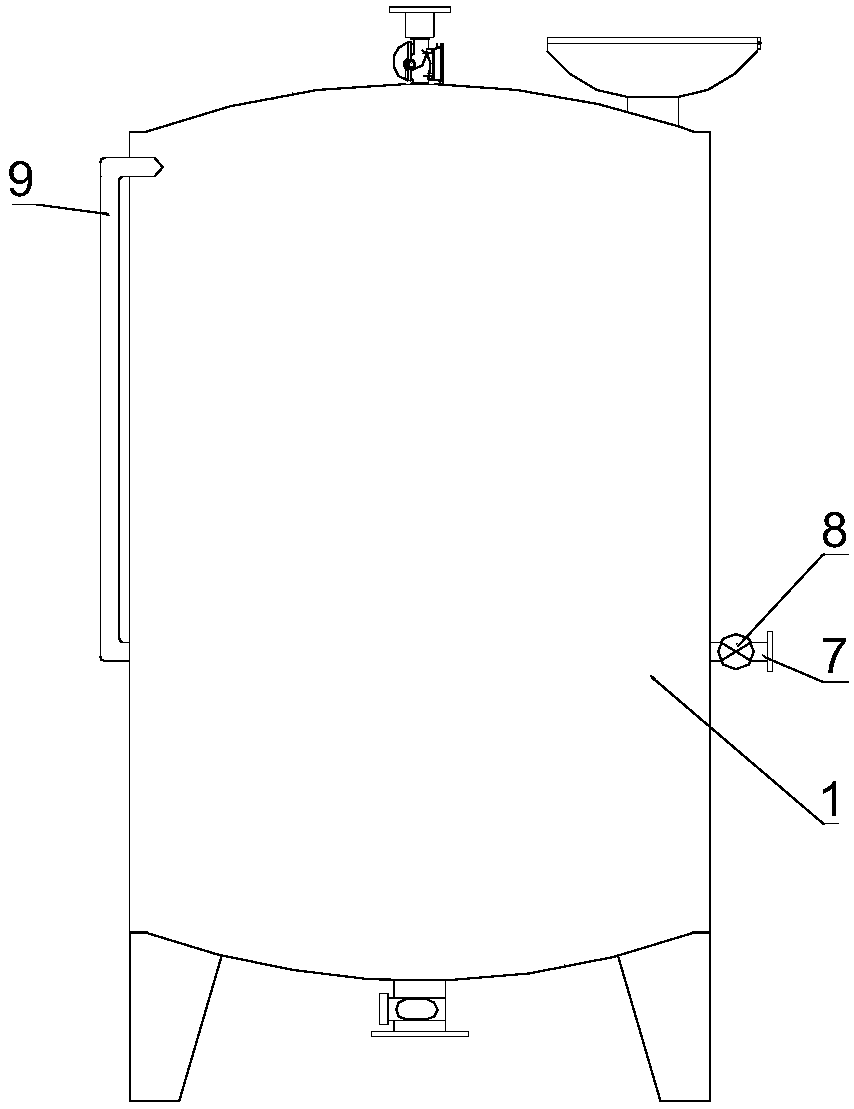

[0027] see Figure 1-3 , a kind of epoxy soybean oil plasticizer production uses the magnetic force pushing type fast decolorizing device, comprises tank body 1, and the inside of described tank body 1 is provided with fixed box 2, and the inside of fixed box 2 is equipped with rotating impeller 3, and the rotating The lower output end of the impeller 3 is fixedly connected with a rotating column 4, the rotating column 4 extends out of the lower side wall of the fixed box 2 and the bottom end of the rotating column 4 is fixedly connected with a U-shaped stirring frame 6, and the surface of the rotating column 4 is fixedly connected There are a number of stirring paddles 5, and the right side wall of the fixed box 2 is fixedly connected with a hydrogen peroxide inlet pipe 7 that runs through the tank body 1, and the hydrogen peroxide inlet pipe 7 lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com