Modified carbon capable of efficiently removing formaldehyde at normal temperature and preparation method of modified carbon

A modified carbon, high-efficiency technology, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve the problems of small molecular weight of formaldehyde, can not meet application requirements, strong polarity, etc., and achieve a simple and easy preparation method. , long-term performance, and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

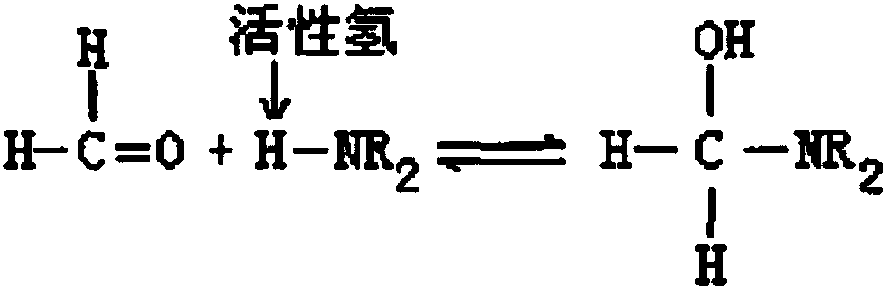

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment 1 provides a method for preparing modified carbon with high efficiency in removing formaldehyde at room temperature, comprising the following steps:

[0024] ① Prepare an organic amine solution with a mass concentration of 1%, and the organic amine is diethylamine;

[0025] ②Adjust the pH value of the above-mentioned organic amine solution to 10.0 with 1mol / L sulfuric acid solution to obtain an organic amine impregnation solution;

[0026] ③ Slowly add activated carbon into the above organic amine impregnation solution with a solid-to-liquid ratio of 1:1, mix well, and impregnate for 40 minutes;

[0027] ④Take out the impregnated activated carbon, and dry it at 110°C for 2 hours to obtain a modified carbon with high efficiency of removing formaldehyde at room temperature.

Embodiment 2

[0029] This Example 2 provides a method for preparing modified carbon with high-efficiency removal of formaldehyde at room temperature, comprising the following steps:

[0030] ① Prepare an organic amine solution with a mass concentration of 3%, and the organic amine is diethylenetriamine;

[0031] ②Adjust the pH value of the above-mentioned organic amine solution to 10.5 with 1mol / L sulfuric acid solution to obtain an organic amine impregnation solution;

[0032] ③ Slowly add activated carbon into the above organic amine impregnation solution with a solid-to-liquid ratio of 1:3, mix well, and impregnate for 35 minutes;

[0033] ④Take out the impregnated activated carbon, and dry it at 105°C for 2 hours to obtain a modified carbon with high efficiency of removing formaldehyde at room temperature.

Embodiment 3

[0035] This embodiment 3 provides a method for preparing modified carbon with high-efficiency removal of formaldehyde at room temperature, comprising the following steps:

[0036] ① Prepare an organic amine solution with a mass concentration of 5%, and the organic amine is triethylenetetramine;

[0037] ②Adjust the pH value of the above-mentioned organic amine solution to 11 with 1mol / L sulfuric acid solution to obtain an organic amine impregnation solution;

[0038] ③ Slowly add activated carbon into the above organic amine impregnation solution with a solid-to-liquid ratio of 1:5, mix well, and impregnate for 30 minutes;

[0039] ④Take out the impregnated activated carbon, and dry it at 95°C for 2 hours to obtain a modified carbon with high efficiency of removing formaldehyde at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com