Degradable metal composite plate for cranio-maxillofacial bone restoration and preparation method thereof

A metal composite plate, craniofacial technology, applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of slow degradation of iron-based metals, difficult to control the degradation time, etc., to achieve excellent biocompatibility The effect of sex and guided defect bone regeneration, simple processing method, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

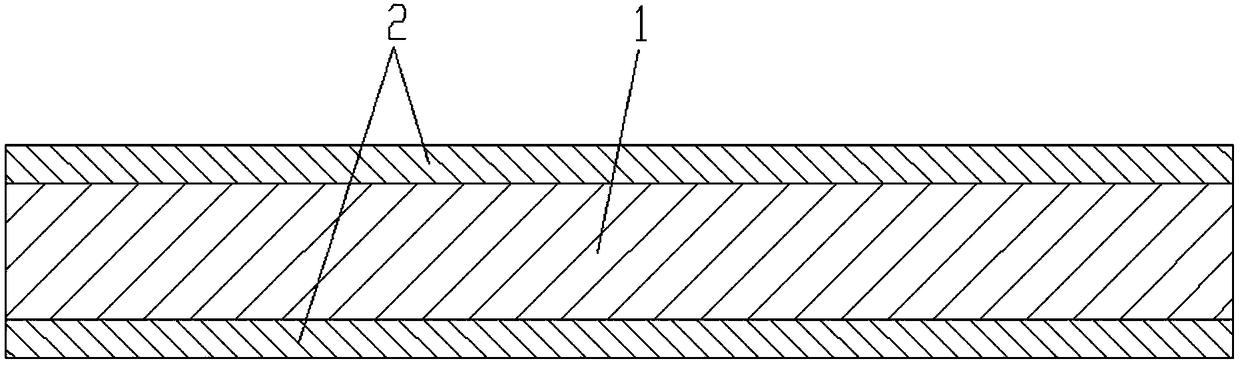

[0022] A method for preparing a degradable metal composite plate for repairing craniomaxillofacial bone, which is mainly made by coating the surface of a magnesium-based or iron-based metal plate 1 with a zinc-based metal plate 2 and then stacking and rolling. The processing method is simple, The parameters of the formed metal composite board are easy to control, and the manufacturing cost is low. Specifically include the following steps:

[0023] Step 1: Before rolling, a plurality of grooves or tetrahedral pits are uniformly and densely distributed on the two surfaces of the magnesium-based or iron-based metal plate 1, and two layers of zinc-based metal plates 2 are respectively coated on the surface. The two surfaces of the magnesium-based or iron-based metal plate 1 with grooves or tetrahedron-shaped pits, and then the rolled front-end faces of the zinc-based metal plate 2 and the magnesium-based or iron-based metal plate 1 clad together are welded together; Wherein, the ...

Embodiment 1

[0028] Take a magnesium-zinc-zirconium alloy plate with a length, width, and thickness of 150mm, 100mm, and 3mm respectively, and a zinc-magnesium-copper alloy plate with a thickness of 0.4mm, and press tetrahedral pits with a depth of 0.15mm on both sides of the magnesium-zinc-zirconium alloy plate. Cover the magnesium-zinc-zirconium alloy plate with a cleaned zinc-magnesium-copper alloy plate with a thickness of 0.4mm, and weld the zinc-magnesium-copper alloy plate and the magnesium-zinc-zirconium alloy plate coated on the rolling front end. Heat the clad plate to 250°C, and control the rolling deformation in a single pass at 10% to 30%. After 6 passes of hot stack rolling, the final plate thickness is controlled to be 1.0mm, so that the thickness of the magnesium-zinc-zirconium alloy plate is about 0.8mm, the single-layer zinc-magnesium-copper alloy plate thickness is about 0.1mm, and the thickness ratio of the magnesium-based metal plate and the zinc-based metal plate in th...

Embodiment 2

[0030]Take a magnesium-zinc-calcium alloy plate with a length, width, and thickness of 80mm, 40mm, and 7.5mm respectively, and a pure zinc plate with a thickness of 0.5mm, and press a tetrahedral pit with a depth of 0.2mm on both sides of the magnesium-zinc-zirconium alloy plate. Cover the magnesium-zinc-calcium alloy plate with a cleaned pure zinc plate with a thickness of 0.5mm, and weld the pure zinc plate coated on the front end of the rolling with the magnesium-zinc-calcium alloy plate. Heat the clad plate to 250°C, and control the rolling deformation in a single pass at 10% to 30%. After 5 passes of hot stack rolling, the final plate thickness is controlled to be 3.4mm, so that the thickness of the magnesium-zinc-calcium alloy plate is about 3mm, the thickness of a single-layer pure zinc plate is about 0.2mm, and the thickness ratio of the magnesium-based metal plate and the zinc-based metal plate in the composite plate is 15. The prepared plate can be used for jaw bone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com