Automatic lamination device for refractory brick production line

A production line and refractory brick technology, which is applied in the field of refractory brick manufacturing, can solve the problems of single refractory material production process, high risk factor for personnel, and large labor consumption, so as to reduce the cost of automated production, coherent and efficient actions, and reduce personnel input. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

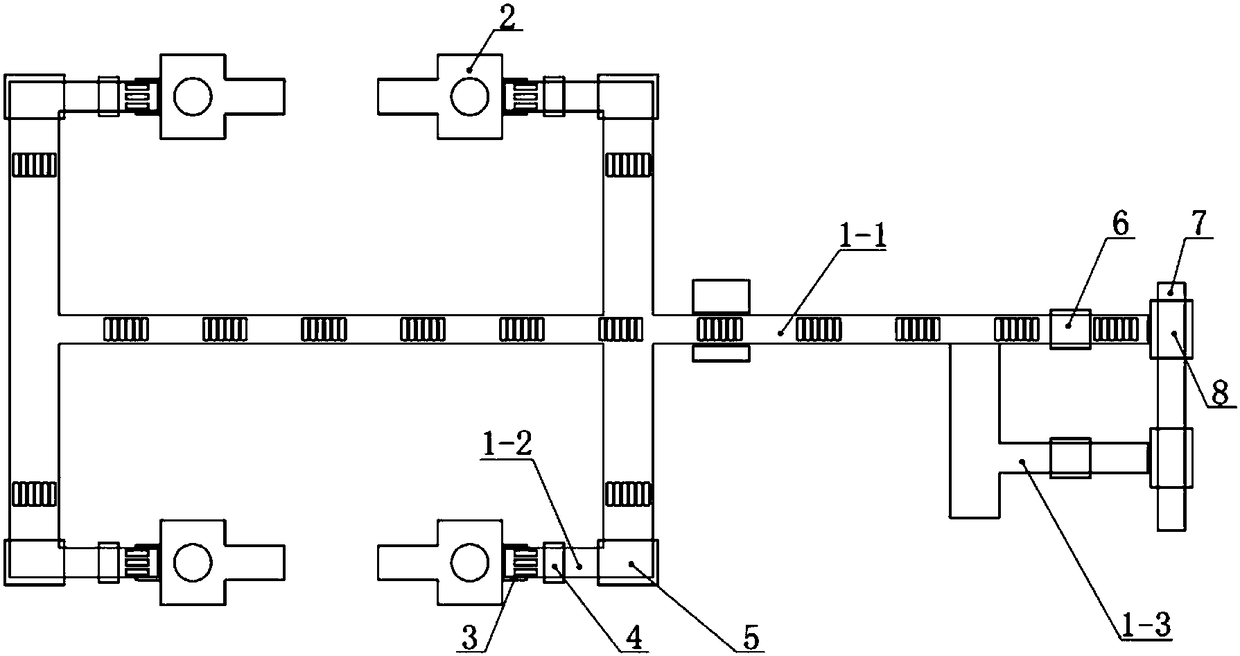

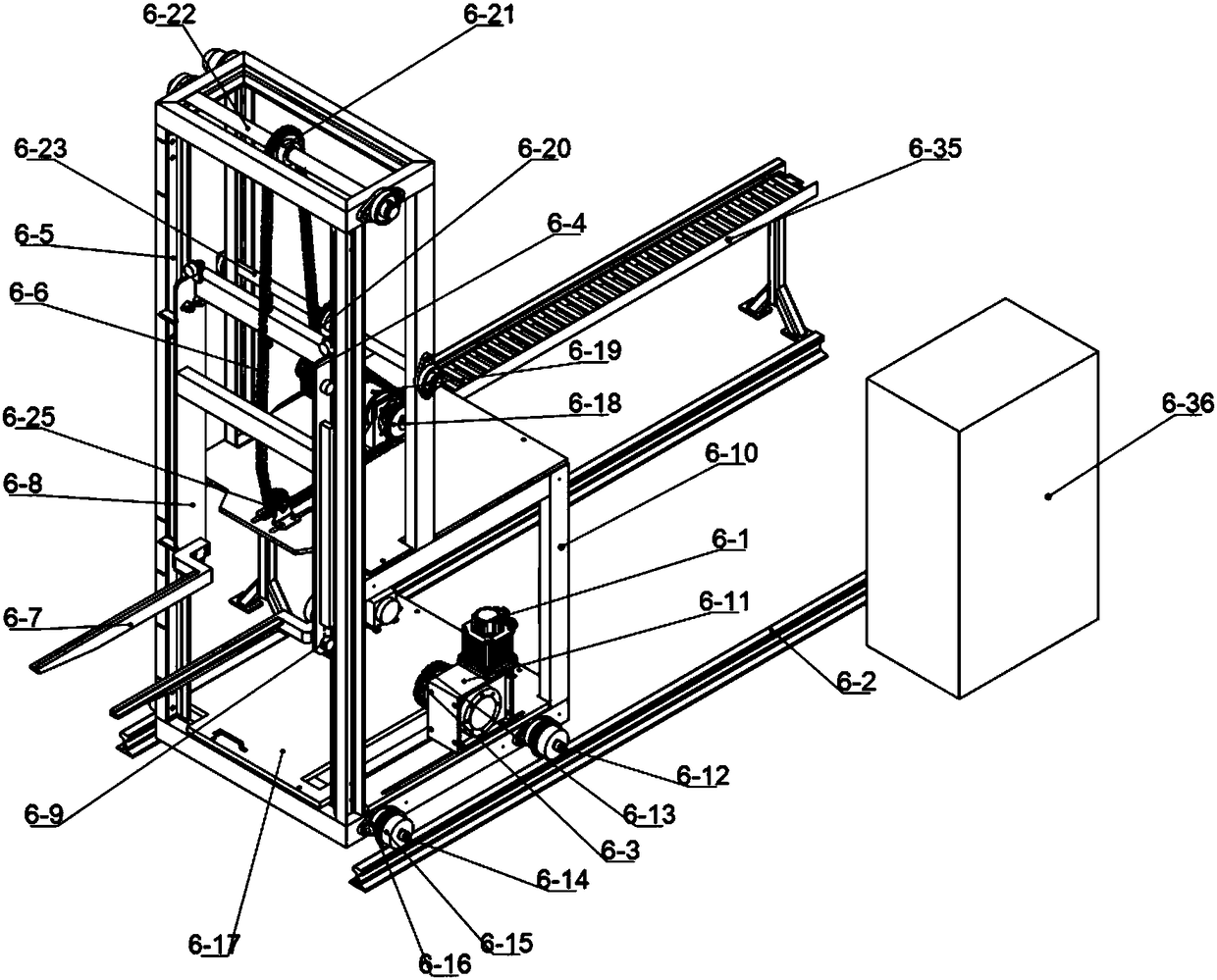

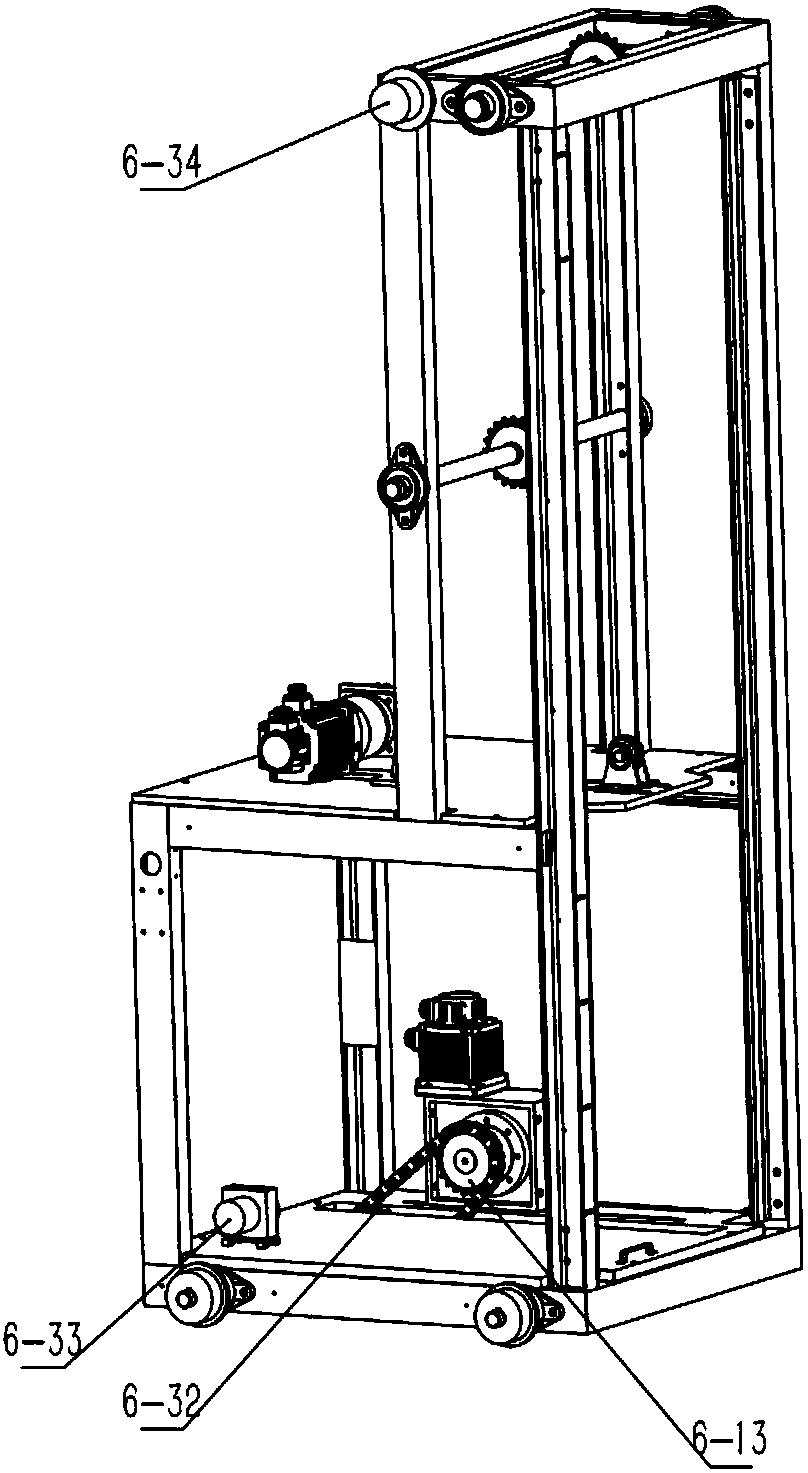

[0040] see figure 1 As shown, the automatic stacking device for a refractory brick production line of this embodiment is figure 1As shown in the winning number 6, it is an important station in the intelligent manufacturing line of refractory bricks. It is located after the automatic line shifting device 5 stations and at the end of the main water line 1-1. It is the last process before the refractory bricks enter the brick kiln. It plays an important role as a link between the preceding and the following. It is mainly responsible for transporting the refractory bricks on the conveying line to the circulation car 8, so as to send the full brick circulation car 8 into the brick kiln for shaping and processing. From figure 1 It can be seen from the figure that after the automatic brick pressing device 2 has pressed the refractory bricks, the automatic brick clamping manipulator 3 moves to the refractory brick output position, and holds the refractory bricks, and transports the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com