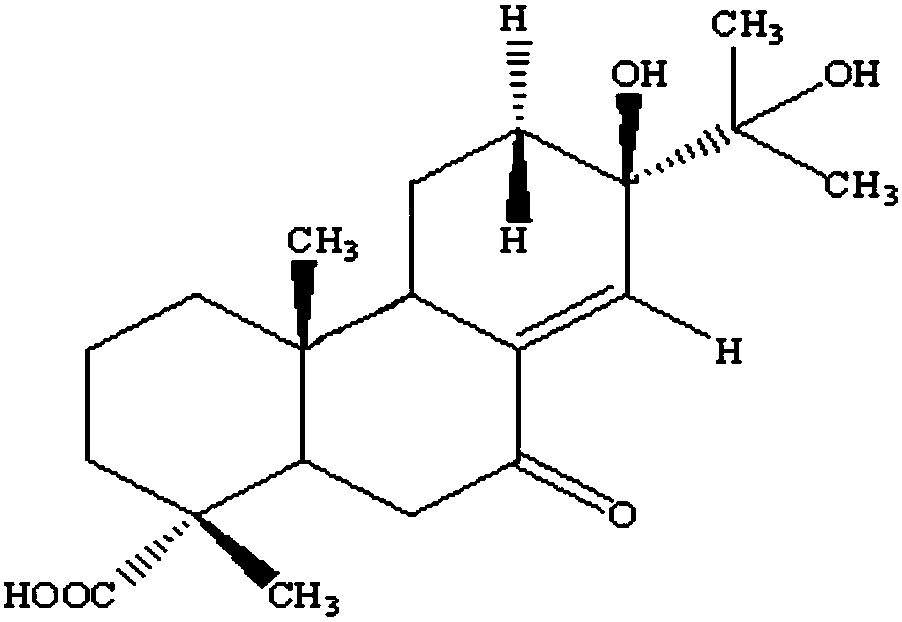

Extraction and separation method of red pinecone essential oil and red pine diterpenoic acid A

A separation method and technology of diterpene acids, which are applied in the separation/purification of carboxylic acid compounds, essential oils/fragrances, fat production, etc., can solve the problems of cumbersome steps, high energy consumption, and loss of essential oils, so as to reduce production costs, Avoid the effects of the purification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Pulverize the Korean pine tower flakes into particles of 150-840 μm, put them into a subcritical extraction tank, turn on stirring, inject 50L of methanol with a concentration of 80% in a vacuum, pressurize and inject 1000L of butane, maintain a pressure of 0.1MPa, and a temperature of 20 ℃ of extraction for 1 hour, recover butane and methanol under reduced pressure to obtain a mixed extract, and discard the solid phase; put the mixed extract into a subcritical extraction tank, turn on stirring, pressurize and inject 800 L of butane, maintain a pressure of 0.1 MPa, and a temperature of 0.1 MPa. Extraction was carried out at 20° C. for 1 hour, butane was recovered under reduced pressure, and the mixed extract and solid phase were obtained again. The above-mentioned obtained mixed extract is frozen for a period of time at -30°C, and the supernatant is obtained by centrifugation to obtain the high-purity Korean pine tower essential oil; the above-mentioned obtained solid ph...

Embodiment 2

[0024] Pulverize the Korean pine tower flakes into particles of 180-600 μm, put them in a subcritical extraction tank, turn on stirring, inject 500L of absolute ethanol in a vacuum, inject 1000L of propane under pressure, maintain a pressure of 2MPa, and extract at a temperature of 40°C for 2 hours. The propane and ethanol were recovered under reduced pressure to obtain a mixed extract, and the solid phase was discarded; the mixed extract was placed in a subcritical extraction tank, stirring was started, and 800 L of propane was injected under pressure, maintaining a pressure of 2 MPa, and the temperature was 40 ° C for extraction for 2 hours, and the reduction of The propane was recovered under pressure, and the mixed extract and solid phase were obtained again. The mixed extracts obtained above were frozen at -20°C for a period of time, and the supernatant was centrifuged to obtain the essential oil of Pinus pagoda; the solid phase obtained above was purified by column chroma...

Embodiment 3

[0026] Pulverize the Korean pine tower flakes into particles of 200-400 μm, put them in a subcritical extraction tank, turn on stirring, inject 500L of anhydrous propanol in a vacuum, pressurize and inject 500L of butane, maintain a pressure of 3MPa, and extract at a temperature of 60°C for 3 After 1 hour, the butane and propanol were recovered under reduced pressure to obtain a mixed extract, and the solid phase was discarded; the mixed extract was put into a subcritical extraction tank, stirring was started, and 800 L of butane was injected under pressure, maintaining a pressure of 3 MPa and a temperature of 60 ° C. Extract for 3 hours, recover butane under reduced pressure, and obtain the mixed extract and solid phase again; freeze the above-obtained mixed extract for a period of time at -10 °C, and centrifuge the supernatant to obtain the essential oil of the Korean pine tower; The solid phase was purified by column chromatography to obtain pure pine diterpene acid A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com